DIN 3352 Gate Valves, ASTM A216 WCB, DN250, 10 IN, PN16, RF

Key Specifications / Features

This DN250 (10-inch) wedge gate valve from our China DIN 3352 factory is cast in rugged ASTM A216 WCB carbon steel, rated to PN16 / Class 150 LB, and finished with raised-face RF flanges for easy, reliable installation. A smooth handwheel drive gives positive shut-off in water, oil or steam lines, combining robust cast body integrity with the proven sealing performance of a solid wedge design.

Detail Information

Product Name: DIN 3352 Wedge Gate Valves

Design Standard: DIN 3352

Body Material: ASTM A216 WCB

Size: DN250, 10 Inch

Pressure: PN16, Class 150 LB

End Connection: RF Flanged

Operation: Handwheel

Medium: Water, Oil, Gas, etc

Temperature Range: -29°C to 595°C

Wedge Gate Valves are engineered and manufactured to achieve volatile organic compound (VOC) leakage rates of less than 100 ppm. Comprehensive baseline laboratory testing, including static and cycle evaluations, has identified critical design parameters essential for ensuring low-emission sealing in both the stem packing and bonnet gasket areas. An in-house testing procedure has been developed and is routinely conducted to verify that standard design and manufacturing processes consistently meet the maximum 100 ppm VOC leakage requirement before shipment.

Technical Specification

» Type: Wedge Gate Valve

» Nominal Diameter: DN50-DN1000

» Design Pressure: PN6-PN25

» Body/Bonnet/Wedge: Cast Steel (EN 1.0619), Stainless Steel (EN 1.4308; EN 1.4408), Alloy Steel EN 1.7335 (WC6)

» Stem: X20Cr13 or EN 1.4021, Stainless Steel (EN 1.4308; EN 1.4408)

» Seat: 13Cr, 18Cr, Stellite

» End Connections: RF Flange, Groove Flange, BW

» Operation: Handwheel, Bevel Gear, Electric, Pneumatic

» Structural Formation: BB-BG-OS & Y

» Design Standard: DIN 3352

» Face-to-Face Dimension: According to EN 558-1 15 (DIN 3202 F5 series)

» Flange Ends: DIN 2543 to 2547, EN 1092-1, GOST 12815, GOST 12819

» Butt Welded End: EN 12627

» Test & Inspection: DIN 3230

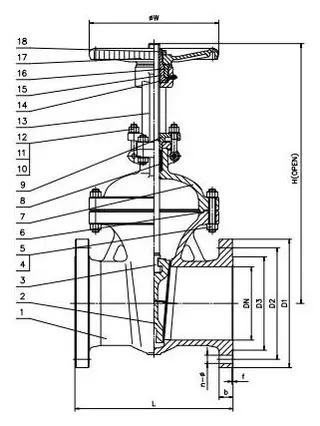

Structural Diagram

Product Features

» Anti-friction ball thrust bearing: Minimizes friction between mating components for smooth operation.

» Grub screw: Secures the yoke nut within the bonnet.

» Grease nipple: Provides lubrication to critical mating parts.

» OS&Y (Outside Stem and Yoke): External stem design for enhanced visibility and maintenance.

» Metal-sealed trims: Available in Trim #1, #5, #8, #10, and other configurations.

» Optional features:

Locking device or stem extension for added security/accessibility.

Direct mounting capability to ISO 5211 standards.

Full port design: Ensures unrestricted flow and minimal pressure drop.