Industry Definition & Scope

The batteries industry encompasses the research, development, manufacturing, and distribution of electrochemical energy storage devices that convert chemical energy into electrical energy. This critical industry serves as the foundational technology for energy storage across consumer electronics, electric mobility, renewable energy integration, and industrial applications. The sector is undergoing a profound transformation driven by electrification and the global energy transition.

Key Product Categories

By Chemistry & Technology:

-

Lead-Acid Batteries: Traditional technology using lead electrodes and sulfuric acid electrolyte, widely used in automotive starting-lighting-ignition (SLI), uninterruptible power supplies (UPS), and some stationary storage. Characterized by low cost and mature recycling infrastructure.

-

Lithium-Ion Batteries: Dominant advanced battery technology using lithium compounds. Subtypes include:

-

Lithium Cobalt Oxide: High energy density, common in consumer electronics.

-

Lithium Iron Phosphate: Superior safety, long cycle life, common in energy storage and EVs.

-

Lithium Nickel Manganese Cobalt Oxide: Balanced performance for EVs and power tools.

-

Lithium Nickel Cobalt Aluminum Oxide: High energy density for premium EVs.

-

-

Nickel-Based Batteries: Including Nickel-Metal Hydride (common in early hybrids) and Nickel-Cadmium (for industrial tools), known for durability but with environmental concerns (Cd).

-

Flow Batteries: Large-scale energy storage technology where energy is stored in liquid electrolytes (e.g., vanadium redox), ideal for long-duration grid storage.

-

Solid-State Batteries: Emerging next-generation technology using solid electrolytes, promising higher energy density, faster charging, and improved safety compared to liquid Li-ion.

-

Sodium-Ion Batteries: Alternative chemistry using abundant sodium, emerging for stationary storage and lower-range EVs as a cost-effective option.

By Application & Market:

-

Consumer Electronics: Batteries for smartphones, laptops, tablets, wearables, and power tools.

-

Electric Vehicles: High-power, high-energy battery packs (battery electric vehicles) and modules (hybrid electric vehicles) for automotive propulsion.

-

Stationary Energy Storage: Systems for grid services, renewable energy integration (solar/wind), backup power, and commercial/industrial peak shaving.

-

Industrial & Motive Power: Batteries for material handling equipment (forklifts), robotics, railway, and marine applications.

Technology & Innovation Trends

-

Next-Generation Chemistries: Intensive R&D on solid-state, lithium-sulfur, and silicon-anode batteries to break current energy density limits.

-

Cell-to-Pack & Structural Battery Technology: Advanced battery pack designs that integrate cells directly into vehicle or system structures to improve volumetric efficiency and reduce weight/cost.

-

Advanced Manufacturing & Gigafactories: Scaling production through highly automated, large-scale factories to achieve economies of scale and drive down costs.

-

Battery Management & Digitalization: Sophisticated BMS with AI/ML for state-of-charge estimation, health monitoring, predictive maintenance, and thermal management optimization.

-

Second-Life & Circular Economy: Repurposing used EV batteries for less demanding stationary storage applications, and developing efficient closed-loop recycling processes for critical materials.

-

Fast-Charging Technology: Development of cell chemistries and system architectures enabling ultra-fast charging (e.g., 10-15 minutes to 80% charge) while maintaining safety and longevity.

Global Market Drivers

-

Global Electrification of Transport: Unprecedented demand from the automotive industry driven by EV mandates, consumer adoption, and corporate fleets transitioning to electric.

-

Renewable Energy Expansion: Critical need for energy storage to manage intermittency of solar and wind power, enabling grid stability and decarbonization.

-

Consumer Electronics Proliferation: Continuous growth in portable electronic devices and the Internet of Things.

-

Government Policies & Incentives: Substantial subsidies, R&D funding, and regulatory frameworks supporting battery manufacturing and EV adoption (e.g., US Inflation Reduction Act, EU Green Deal).

-

Grid Modernization & Resilience: Investments in grid infrastructure to incorporate storage for peak shaving, frequency regulation, and backup power.

-

Decarbonization of Industrial Processes: Electrification of heating, machinery, and heavy transport creating new storage demand.

Industry Value Chain

-

Raw Material Mining & Refining: Extraction and processing of lithium, cobalt, nickel, graphite, manganese, and other critical minerals.

-

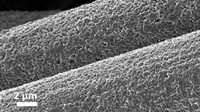

Material Production: Manufacturing of cathodes, anodes, electrolytes, separators, and other cell components.

-

Cell Manufacturing: Production of individual battery cells through electrode coating, assembly, formation, and aging processes.

-

Module & Pack Assembly: Integration of cells into modules and complete battery packs with BMS, thermal management, and enclosure.

-

System Integration: Incorporation of battery packs into final products (EVs, energy storage systems).

-

End-of-Life Management: Collection, testing, repurposing (second-life), and recycling of spent batteries.

Key Industry Challenges

-

Supply Chain Security & Geopolitics: Concentration of raw material mining and processing in a few countries creating supply risks and price volatility.

-

High Capital Intensity: Massive investments required for gigafactories and R&D, creating high barriers to entry.

-

Safety & Thermal Runaway Risks: Managing safety incidents (fires) remains a critical engineering and reputational challenge, especially at scale.

-

Cost Pressure & Commoditization: Intense competition, especially in consumer electronics and evolving EV segments, pressures margins.

-

Performance Trade-offs: Balancing energy density, power density, cycle life, safety, and cost across different applications.

-

Recycling Infrastructure Scale-Up: Building cost-effective, large-scale recycling capacity to handle the coming wave of battery waste and secure material supply.

Future Outlook

The batteries industry is poised for decades of transformative growth, becoming a cornerstone of the modern economy.

-

Terawatt-Hour Scale Production: Manufacturing capacity will expand orders of magnitude to meet demand across transport and energy sectors.

-

Diversification of Chemistries: No single chemistry will dominate all applications; the portfolio will expand based on application-specific needs (cost, energy, power, safety).

-

Deep Integration with Energy Systems: Batteries will become fundamental grid assets, enabling higher renewable penetration and new utility business models.

-

Advanced AI-Powered BMS: Battery management will evolve into predictive health analytics platforms, maximizing value over the entire lifecycle.

-

Sustainability as Core Competency: Supply chain transparency, low-carbon manufacturing, and circular design will become key competitive differentiators.

-

Standardization & Interoperability: Industry-wide standards for form factors, interfaces, and second-life testing will emerge to facilitate scaling and recycling.