Industry Definition & Scope

The pumps and parts industry encompasses the design, manufacturing, distribution, and servicing of devices (pumps) and their components that move fluids (liquids, gases, or slurries) by mechanical action. This foundational industrial sector supports virtually every modern industry—from water supply and energy production to chemical processing and manufacturing—by providing critical fluid handling solutions. The industry combines mechanical engineering, material science, hydraulics, and increasingly, digital technologies to deliver efficient, reliable, and smart pumping systems.

Key Product Categories

-

By Pump Type & Operating Principle:

-

Centrifugal Pumps: Utilize a rotating impeller to impart kinetic energy (most common type).

-

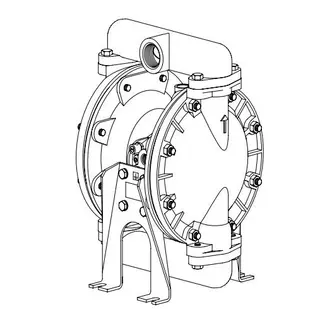

Positive Displacement Pumps: Trap and move fixed volumes of fluid (e.g., gear, piston, diaphragm, peristaltic pumps).

-

Rotary Pumps: Gear, screw, vane, and lobe pumps for viscous fluids.

-

Reciprocating Pumps: Piston/plunger and diaphragm pumps for high pressure.

-

Specialty Pumps: Magnetic drive pumps (sealless), cryogenic pumps, submersible pumps, metering pumps.

-

-

By Key Components & Parts:

-

Hydraulic End Parts: Impellers, casings, volutes, diffusers, wear rings.

-

Mechanical End Parts: Shafts, sleeves, bearings, couplings, seals (mechanical seals, packing).

-

Power & Drive Parts: Motors, drives (VFDs), bases, couplings.

-

Auxiliary & Control Parts: Valves, gauges, sensors, control panels, lubrication systems.

-

Consumables & Wear Parts: O-rings, gaskets, diaphragms, valves (for PD pumps).

-

-

By Application & Industry:

-

Water & Wastewater: Clean water supply, sewage/stormwater, treatment plants.

-

Oil & Gas: Upstream (drilling, crude transfer), midstream (pipeline), downstream (refining).

-

Chemical & Process: Acid/alkali transfer, solvent handling, process circulation.

-

Power Generation: Boiler feedwater, cooling water circulation, condensate, FGD.

-

Mining & Minerals: Slurry transport, tailings, dewatering, mineral processing.

-

Building Services: HVAC, firefighting, plumbing, pressure boosting.

-

Food & Beverage / Pharmaceutical: Sanitary pumps, CIP systems, hygienic fluid transfer.

-

-

By Technology & Features:

-

Standard Pumps: General-purpose designs.

-

Engineered/Process Pumps: Customized for specific duties (API 610, ISO 5199).

-

Smart Pumps: Integrated sensors, IoT connectivity, predictive maintenance capabilities.

-

Energy-Efficient Pumps: Optimized hydraulics and motor-drive systems.

-

Technology & Innovation Trends

-

Advanced Design & Manufacturing:

-

Computational Fluid Dynamics (CFD) and Finite Element Analysis (FEA) for optimized hydraulic and mechanical design.

-

Additive Manufacturing (3D printing) for complex impellers, prototypes, and custom parts.

-

Advanced coatings (thermal spray, CVD/PVD) and materials (super duplex, composites) for wear/corrosion resistance.

-

Laser scanning and digital twins for pump performance simulation and lifecycle management.

-

-

Digitalization & Smart Systems:

-

IIoT sensors monitoring vibration, temperature, pressure, and flow in real-time.

-

AI and machine learning for predictive maintenance, fault diagnosis, and efficiency optimization.

-

Cloud-based pump management platforms for fleet monitoring and energy analytics.

-

Integrated motor-pump systems with variable speed drives for optimal system control.

-

-

Sustainability & Energy Efficiency:

-

Development of pumps meeting stringent efficiency regulations (e.g., EU Ecodesign, US DOE standards).

-

Systems approach optimization, moving beyond pump unit efficiency to overall system efficiency.

-

Water and wastewater pumps designed for resource recovery (energy, nutrients).

-

Lightweight designs and recyclable material usage.

-

-

Material & Seal Technology:

-

New elastomers and thermoplastics for challenging chemical services.

-

Advanced mechanical seal designs (dry gas seals, tandem seals) for zero emissions.

-

Magnetic bearing technology in high-speed pumps for oil-free operation.

-

Global Market Drivers

-

Global urbanization and infrastructure development driving water and wastewater investments.

-

Energy transition, including growth in LNG, hydrogen, biofuels, and carbon capture.

-

Strict environmental regulations on emissions, energy use, and water treatment.

-

Aging infrastructure in developed economies requiring replacement and upgrade.

-

Industrialization and water stress in emerging markets.

-

Growth in pharmaceutical, food processing, and data center cooling markets.

-

Increasing focus on operational efficiency (OPEX reduction) and predictive maintenance.

Major Players & Value Chain

-

Global Pump Manufacturers:

-

Broad-line: Grundfos (Denmark), Xylem (US), KSB (Germany), Sulzer (Switzerland), Flowserve (US), Wilo (Germany).

-

Specialists: SPX Flow (APV, Lightnin), ITT Goulds Pumps, Ebara, Torishima.

-

-

Component & Parts Specialists:

-

Seals: John Crane, EagleBurgmann, Flowserve, AESSEAL.

-

Motors & Drives: ABB, Siemens, WEG, Nidec.

-

Bearings & Mechanical Parts: SKF, NSK, Timken.

-

-

Regional Leaders: China (CNP, Shimge), India (Kirloskar, Shakti), Japan.

-

Value Chain:

-

Raw Materials → Component Manufacturing (castings, forgings, machining) → Pump Assembly → Testing → Sales & Distribution (OEM, Distributor, E-commerce) → System Integration & Installation → Aftermarket Services (MRO, Parts, Repair) → End Users.

-

Challenges & Opportunities

-

Challenges:

-

Intense competition, especially in standardized pump segments.

-

Volatility in raw material costs (metals, polymers).

-

Skilled labor shortage for service, repair, and system engineering.

-

Long replacement cycles and price sensitivity in aftermarket parts.

-

Complexity of integrating pumps into smart industrial ecosystems.

-

-

Opportunities:

-

Growth in smart pump and pump-as-a-service business models.

-

Expansion in renewable energy and decarbonization-related applications.

-

Digital services (remote monitoring, predictive maintenance, digital twins).

-

Water scarcity and circular economy driving advanced treatment and reuse.

-

Emerging market infrastructure build-out.

-

Customization and system solutions for complex industrial processes.

-

Lightweight and compact designs for new applications (e.g., electric vehicle thermal management).

-