Industry Definition & Scope

The electrical instruments industry encompasses the design, manufacturing, and distribution of devices used to measure, monitor, test, analyze, and display electrical parameters, signals, and energy-related phenomena. This specialized sector provides essential tools for electrical system operation, maintenance, safety verification, quality control, and research across power utilities, industrial facilities, commercial buildings, and residential applications. The industry bridges fundamental electrical theory with practical engineering applications through precision measurement technology.

Key Product Categories

By Core Measurement Function:

-

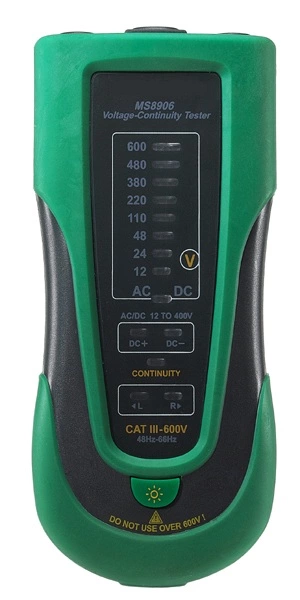

Basic Electrical Parameter Meters: Multimeters (digital/analog), clamp meters, voltage testers, and continuity testers for measuring voltage, current, resistance, and basic circuit characteristics.

-

Power & Energy Measurement Instruments: Power quality analyzers, energy meters (watt-hour meters), power factor meters, and harmonic analyzers for monitoring electrical consumption, efficiency, and waveform distortion.

-

Insulation & Safety Test Equipment: Insulation resistance testers (meggers), dielectric testers, ground resistance testers, and earth continuity testers for evaluating electrical safety and component integrity.

-

Electrical Protection & Relay Test Sets: Specialized equipment for testing circuit breakers, protective relays, and overcurrent devices to ensure proper operation of electrical protection systems.

-

Electrical Installation Testers: Multifunction test instruments for verifying compliance with electrical codes (e.g., IEC 60364, NEC), including loop impedance testers, RCD/GFCI testers, and prospective fault current testers.

-

Process & Industrial Electrical Instruments: Panel meters, transducers, signal conditioners, and process indicators for monitoring electrical parameters in industrial control systems.

By Technology & Form Factor:

-

Handheld/Portable Instruments: Battery-operated, field-serviceable devices designed for troubleshooting, commissioning, and maintenance work.

-

Benchtop/Laboratory Instruments: Higher-precision stationary devices for calibration, research, and development applications.

-

Panel-Mounted/Installation Instruments: Fixed instruments integrated into switchboards, control panels, and electrical distribution boards for continuous monitoring.

-

Modular & System Instruments: Configurable measurement systems for automated testing and data acquisition applications.

-

Smart & Connected Instruments: Network-enabled devices with data logging, wireless connectivity, and cloud integration capabilities.

Technology & Innovation Trends

-

True-RMS & High-Accuracy Measurement: Advanced analog-to-digital conversion and signal processing enabling accurate measurements on non-linear loads and complex waveforms.

-

Wireless Connectivity & IoT Integration: Bluetooth, Wi-Fi, and cellular connectivity for remote monitoring, data sharing, and integration with building management systems.

-

Enhanced Safety Features: Higher category safety ratings (CAT IV), arc flash detection, non-contact voltage detection, and insulated designs for safer operation.

-

Data Logging & Advanced Analysis: Built-in memory, GPS tagging, and sophisticated software for long-term trending, event capture, and report generation.

-

Multi-Function Instrument Platforms: Single devices combining multiple testing functions (e.g., insulation resistance, loop impedance, RCD testing) to reduce instrument count and improve efficiency.

-

Low-Power & Energy Harvesting Designs: Efficient circuits enabling extended battery life and instruments powered by ambient energy sources.

-

Augmented Reality & Mobile Integration: Smartphone apps and AR interfaces providing guided measurements, documentation support, and remote expert assistance.

Global Market Drivers

-

Electrical Infrastructure Modernization: Aging power grids, substation upgrades, and smart grid deployments driving demand for advanced monitoring and testing equipment.

-

Renewable Energy Integration: Growth in solar, wind, and energy storage systems requiring specialized measurement and protection testing.

-

Stringent Safety Regulations & Electrical Standards: Compliance requirements (OSHA, NFPA 70E, IEC standards) mandating regular electrical testing and documentation.

-

Industrial Automation & Industry 4.0: Increased need for electrical monitoring in automated manufacturing processes and predictive maintenance programs.

-

Building Electrification & EV Charging Infrastructure: Expansion of electrical systems in buildings and installation of EV charging stations creating new testing requirements.

-

Energy Efficiency & Sustainability Initiatives: Demand for instruments that help optimize energy consumption and reduce electrical losses.

-

Skilled Labor Shortage: Need for more efficient, user-friendly instruments that help less-experienced technicians perform complex measurements accurately.

Industry Value Chain

-

Component Suppliers: Semiconductor manufacturers (ADC/DAC chips), display makers, sensor producers, and precision component suppliers.

-

Instrument Design & Manufacturing: Companies specializing in electrical design, mechanical engineering, firmware development, and final assembly.

-

Calibration & Metrology Services: Accredited laboratories providing traceable calibration and performance verification services.

-

Distribution & Sales Channels: Electrical wholesalers, specialized distributors, direct sales teams, and online platforms.

-

System Integrators & Service Providers: Companies that incorporate instruments into larger testing solutions and provide field services.

-

End Users: Electric utilities, industrial plants, electrical contractors, facility managers, maintenance teams, and electrical inspectors.

Key Industry Challenges

-

Balancing Performance with Cost: Meeting demanding accuracy and safety specifications while maintaining competitive pricing for diverse market segments.

-

Rapid Technological Evolution: Keeping pace with changes in electrical systems (e.g., higher voltages, power electronics) and measurement technologies.

-

Global Standards & Certification Complexity: Navigating different regional safety standards, measurement accuracy requirements, and certification processes.

-

Product Differentiation: Distinguishing offerings in a market with many competitors offering similar basic functionality.

-

Supply Chain Constraints: Dependence on specialized electronic components and susceptibility to semiconductor shortages.

-

Training & Knowledge Transfer: Ensuring users understand proper instrument operation, safety procedures, and interpretation of measurement results.

-

Data Security Concerns: Protecting measurement data and network-connected instruments from cybersecurity threats.

Future Outlook

-

Convergence with IT & Data Analytics: Electrical instruments becoming data sources for comprehensive energy management and predictive maintenance platforms.

-

Increased Automation in Testing: Development of automated testing routines, robotic measurement systems, and AI-assisted diagnostics.

-

Enhanced User Experience: More intuitive interfaces, voice control, and contextual help systems to reduce training requirements and minimize operator error.

-

Sustainability-Focused Measurements: Specialized instruments for carbon footprint tracking, renewable energy system optimization, and circular economy assessments.

-

Digital Twin Integration: Electrical instruments providing real-time data for virtual models of electrical systems, enabling simulation and optimization.

-

Expansion into New Energy Systems: Development of instruments for hydrogen infrastructure, advanced battery systems, and microgrid applications.

-

Servitization & Outcome-Based Models: Shift from product sales to service offerings including instrument-as-a-service, data analytics subscriptions, and performance-based contracts.