1. Industry Definition & Scope

The Plastic Pipes Industry encompasses the manufacturing, distribution, and application of tubular products made from synthetic polymers, designed for the conveyance of fluids (water, gas, chemicals), solids, or for protective electrical and telecommunications conduit. It is a critical component of global infrastructure, serving construction, agriculture, utilities, and industrial sectors, and has increasingly replaced traditional materials like metal and clay due to its cost-effectiveness, durability, and installation advantages.

2. Major Product Categories (By Material & Application)

-

By Primary Polymer Type:

-

PVC (Polyvinyl Chloride) & CPVC (Chlorinated Polyvinyl Chloride):

-

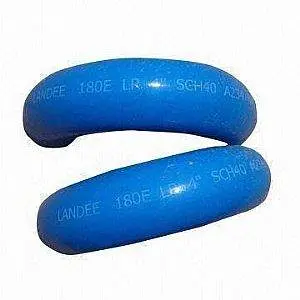

PVC-U (Unplasticized): For pressure water mains, sewer/drainage, irrigation. Dominant in non-potable and drainage.

-

CPVC: For hot and cold potable water distribution (higher temperature resistance).

-

-

PE (Polyethylene):

-

HDPE (High-Density PE): For gas distribution, potable water mains, mining/slurry lines, geothermal. Known for flexibility and joint integrity (butt fusion).

-

MDPE & LDPE: Used in lower pressure applications, agriculture.

-

PEX (Cross-linked Polyethylene): Primarily for indoor potable water plumbing (hot/cold) and radiant floor heating systems.

-

-

PP (Polypropylene):

-

PP-R (Random Copolymer): For hot and cold potable water systems, especially in Europe and Asia. Good chemical/heat resistance.

-

-

ABS (Acrylonitrile Butadiene Styrene): For drain-waste-vent (DWV) systems, primarily in residential construction in some regions.

-

PB (Polybutylene): Historically used for potable water, now largely replaced due to failure issues.

-

-

By Application & Market:

-

Potable Water Supply: Municipal water distribution networks, house service connections.

-

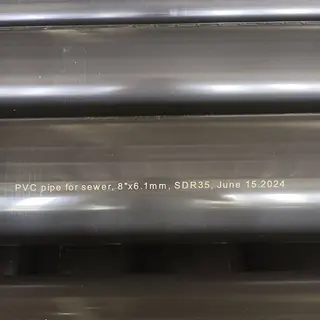

Sewerage & Drainage: Sanitary sewers, stormwater drainage, soil and waste systems in buildings.

-

Gas Distribution: Network for natural gas and LPG (primarily HDPE and MDPE).

-

Industrial & Process Piping: For chemicals, slurries, compressed air in factories.

-

Agriculture & Irrigation: Drip and sprinkler systems, water transfer.

-

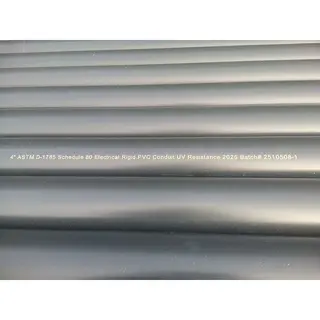

Electrical & Telecom Conduit: Protection for cables and fiber optics (mainly PVC).

-

Heating & Plumbing: Indoor systems (PEX, PP-R, CPVC).

-

Mining & Geothermal: HDPE for abrasive/corrosive slurry and geothermal loops.

-

3. Industry Chain Structure

Upstream:

-

Petrochemical Industry: Producers of base monomers (ethylene, propylene, vinyl chloride) and polymer resins.

-

Additive Suppliers: Manufacturers of stabilizers (e.g., for heat/UV resistance), plasticizers, colorants, lubricants, and modifiers.

Midstream:

-

Pipe & Fitting Manufacturers: The core of the industry. Use extrusion processes for pipes and injection molding for fittings (elbows, tees, couplings).

-

Global Leaders: Uponor, Wavin (part of Mexichem), Georg Fischer, Aliaxis, China Lesso, Sekisui Chemical.

-

-

Machinery Suppliers: Companies supplying extruders, dies, haul-offs, and printing/coding equipment.

Downstream:

-

Distributors & Wholesalers: Stock and supply pipes/fittings to contractors and retailers.

-

Utilities & Municipalities: Major buyers for large-diameter water, sewer, and gas infrastructure projects.

-

Construction Contractors & Plumbers: Install pipes in residential, commercial, and industrial projects.

-

Engineering & Consulting Firms: Specify pipe materials and designs for projects.

-

End Users: Homeowners, farmers, industrial plant operators.

4. Key Market Dynamics & Characteristics

-

Strong Correlation with Construction & Infrastructure Investment: Demand is directly tied to new construction activity and government spending on water, sewer, and gas networks.

-

Material Substitution Driver: Plastic pipes continue to gain market share from ductile iron, concrete, and steel due to lower installed cost, corrosion resistance, and longer design life.

-

Price Sensitivity to Raw Materials: Profit margins are heavily influenced by the volatile prices of petrochemical feedstocks (ethylene, propylene).

-

Regulation & Standard Intensive: Products must comply with stringent national and international standards for pressure ratings, safety (e.g., for potable water contact), fire performance (in buildings), and environmental impact.

-

Long Product Lifecycle & Durability Focus: Pipes are expected to last for decades, making material performance and certification critical.

5. Development Trends

-

Sustainability & Circular Economy:

-

Increased use of recycled content (post-industrial and post-consumer) in pipe production, especially for non-pressure applications.

-

Development of fully recyclable mono-material pipe systems.

-

Energy efficiency in production and the lower pumping energy requirement of smooth plastic pipes.

-

-

Large-Diameter & Advanced Applications:

-

Expansion into larger diameter pipes for major municipal gravity sewers and water mains, competing directly with concrete and steel.

-

Growth in trenchless technology (e.g., HDPE sliplining) for rehabilitating old pipelines, favoring plastic's flexibility.

-

-

Smart Piping Systems:

-

Integration of sensors and RFID tags during manufacture for asset management, leak detection, and maintenance tracking in utility networks.

-

-

Material & Compound Innovation:

-

Development of enhanced PVC and PE compounds for higher pressure ratings, better crack resistance, and improved sustainability profiles.

-

Bio-based and biodegradable plastics exploration for specific, non-structural applications.

-

-

Modular & Prefabricated Construction:

-

Rise of prefabricated plumbing modules using plastic pipes, improving construction speed and quality on-site.

-

6. Major Challenges & Opportunities

Challenges:

-

Raw Material Volatility: Managing costs amidst fluctuating oil/petrochemical prices.

-

Environmental Scrutiny on Plastics: Public and regulatory pressure regarding plastic waste, microplastics, and the carbon footprint of virgin plastics.

-

Competition in Mature Markets: Intense price competition, particularly in standard PVC and PE segments.

-

Technical Misconceptions & Code Adoption: Overcoming outdated perceptions about plastic pipe performance and navigating slow updates to local building codes.

-

Recycling Infrastructure for End-of-Life Pipes: Developing efficient collection and reprocessing systems for pipes removed from service.

Opportunities:

-

Global Water & Sanitation Infrastructure Gap: Massive investment needed in emerging economies for clean water and sewage systems.

-

Replacement of Aging Infrastructure: In developed nations, the need to replace old metal and concrete pipes drives demand.

-

Urbanization & Mega-City Development: Creating unprecedented demand for dense utility networks.

-

Renewable Energy & District Energy Systems: Growth in geothermal and district heating/cooling networks utilizing HDPE and PEX pipes.

-

Digitalization & Smart Cities: Offering value-added smart pipe solutions for efficient utility management.