Industry Definition & Scope

The abrasives industry encompasses the design, manufacturing, and distribution of hard materials used for grinding, polishing, cutting, honing, and surface preparation across virtually all manufacturing and maintenance sectors. As essential consumables in material processing, abrasives enable precision shaping, finishing, and surface treatment of metals, ceramics, glass, wood, composites, and various other materials. This industry combines materials science, precision engineering, and application technology to provide critical solutions for manufacturing efficiency, quality control, and surface integrity.

Key Product Categories

-

By Product Form:

-

Coated Abrasives: Sandpaper, abrasive belts, discs, sheets, rolls

-

Bonded Abrasives: Grinding wheels, cutting wheels, honing stones, mounted points

-

Superabrasives: Diamond and cubic boron nitride (CBN) products

-

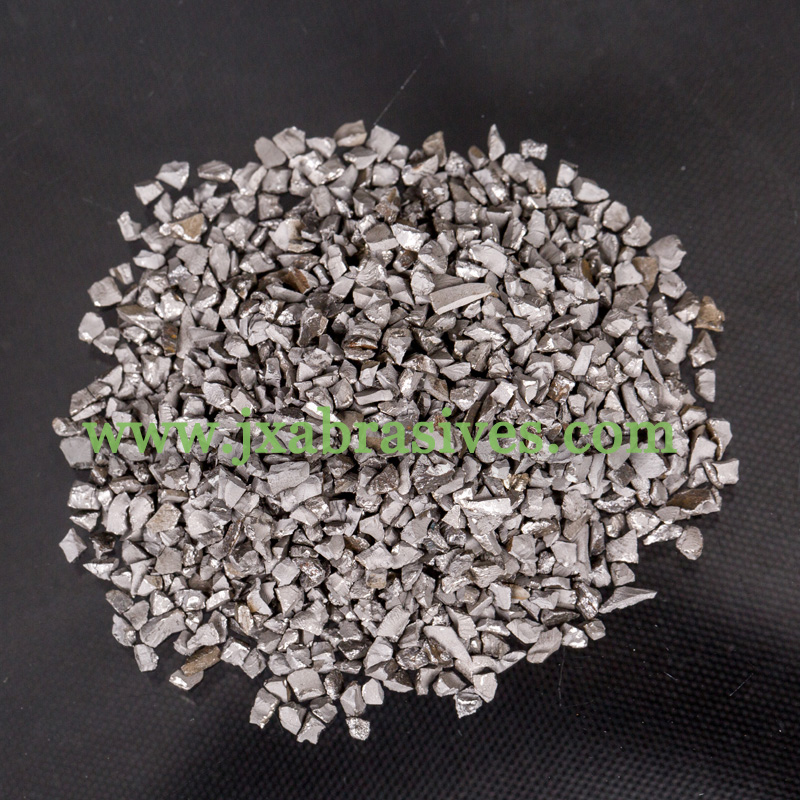

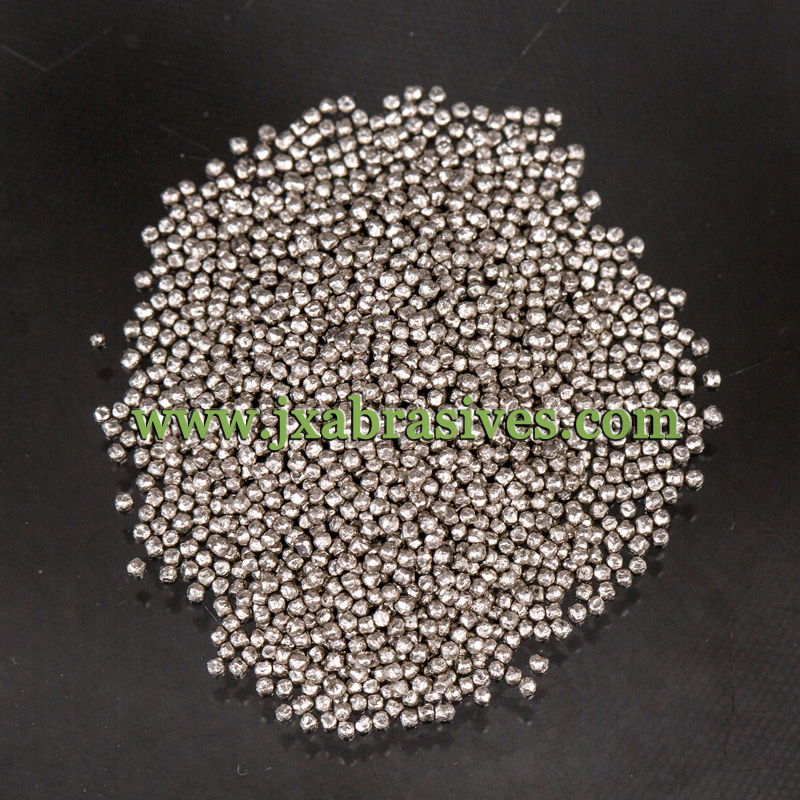

Loose Abrasives: Grains, powders, compounds for lapping and polishing

-

Non-Woven Abrasives: Scouring pads, finishing pads, surface conditioning products

-

-

By Material Composition:

-

Conventional Abrasives: Aluminum oxide, silicon carbide, garnet, emery

-

Superabrasives: Synthetic diamond, CBN for hard materials and precision applications

-

Natural Abrasives: Pumice, quartz, flint, natural diamonds

-

Composite Abrasives: Ceramic abrasives, seeded gel abrasives, hybrid formulations

-

-

By Application Sector:

-

Metalworking: Grinding, deburring, surface preparation in automotive, aerospace, machinery

-

Woodworking: Sanding, shaping, finishing of wood and wood composites

-

Construction: Surface preparation, concrete grinding, stone polishing

-

Electronics: Wafer polishing, component finishing, micro-abrasion

-

Precision Manufacturing: Optical lens polishing, medical device finishing, mold making

-

Maintenance, Repair & Operations (MRO): General maintenance, refurbishment, repair work

-

-

By Grain Technology:

-

Conventional Grains: Standard friable and semi-friable abrasives

-

Engineered Grains: Precisely shaped, uniform particles for consistent performance

-

Micro-abrasives: Ultrafine grains for high-precision finishing

-

Agglomerated Grains: Clustered abrasives for controlled breakdown and extended life

-

Technology & Innovation Trends

-

Advanced Material Development:

-

Sol-gel and seeded gel ceramic abrasives for superior performance

-

Nano-crystalline diamond and CBN for extreme hardness and wear resistance

-

Bio-based abrasive materials from agricultural byproducts

-

Self-sharpening abrasive grains maintaining consistent cutting action

-

-

Manufacturing Innovations:

-

3D printing of abrasive tools with complex internal structures

-

Laser marking and sorting for quality traceability

-

Automated grain alignment in coated abrasives

-

Precision bonding technologies for uniform distribution and retention

-

-

Digital Integration:

-

IoT-enabled abrasive tools with wear sensors and usage monitoring

-

AI-based abrasive selection systems matching materials and applications

-

Digital twin simulations for abrasive tool performance prediction

-

Blockchain for supply chain transparency and quality certification

-

-

Sustainability & Safety:

-

Low-dust and dust-extraction compatible abrasive formulations

-

Water-based and solvent-free bonding systems

-

Recyclable abrasive products and closed-loop material recovery

-

Reduced energy consumption in abrasive manufacturing processes

-

Global Market Drivers

-

Growth in global manufacturing, particularly automotive, aerospace, and machinery sectors

-

Increasing demand for precision components in electronics and medical devices

-

Infrastructure development and construction activity worldwide

-

Rising automation requiring consistent, reliable abrasive performance

-

Stringent quality standards in surface finish and dimensional accuracy

-

Growth in renewable energy sectors (wind turbine blade finishing, solar panel manufacturing)

-

Replacement demand in maintenance and repair markets

-

Technological advancements enabling new applications and efficiency improvements

Major Players & Value Chain

-

Global Leaders: Saint-Gobain (Norton), 3M, Tyrolit, Hermes Schleifmittel, Fujimi

-

Superabrasive Specialists: Element Six, ILJIN Diamond, Henan Huanghe Whirlwind

-

Regional Powerhouses: Chinese abrasives manufacturers (Zhengzhou, Shandong clusters)

-

Value Chain: Raw material mining/synthesis → grain production → bonding/coating → tool manufacturing → testing/classification → distribution → end-user application

Challenges & Opportunities

-

Challenges:

-

Raw material price volatility and supply chain disruptions

-

Intense competition, especially in standard abrasive segments

-

Environmental regulations on dust emissions and waste disposal

-

Skilled labor shortage in abrasive application and tool manufacturing

-

Rapid technological change requiring continuous R&D investment

-

-

Opportunities:

-

Growth in precision manufacturing and nanotechnology applications

-

Sustainable and eco-friendly abrasive product development

-

Digitalization and smart abrasive tool integration

-

Emerging market industrialization driving demand

-

Customized solutions for specific applications and materials

-

Additive manufacturing support with specialized abrasive tools

-

Circular economy models through abrasive recycling and reconditioning

-