Industry Definition & Scope

The alloy steel pipes industry encompasses the design, manufacturing, and application of tubular products made from steel alloyed with elements such as chromium, molybdenum, nickel, and vanadium to achieve enhanced mechanical properties and corrosion resistance. These specialized pipes are engineered for extreme service conditions in critical industries where standard carbon steel pipes are insufficient, making them indispensable for high-temperature, high-pressure, and corrosive environments.

Key Product Categories

-

By Alloy Composition:

-

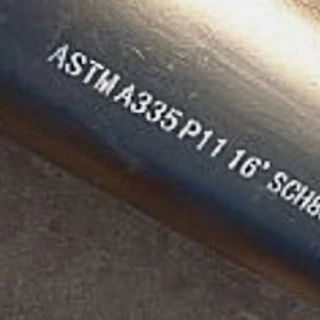

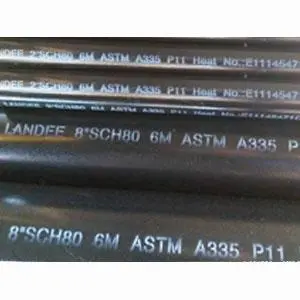

Chromium-Molybdenum (Cr-Mo) Pipes: ASTM A335 Gr.P5/P9/P11/P22/P91 for high-temperature service

-

Nickel Alloy Pipes: Incoloy, Inconel, Hastelloy for severe corrosion resistance

-

Duplex/Super Duplex Pipes: 2205, 2507 grades for chloride-rich environments

-

Low-Temperature Alloy Pipes: 3.5% nickel steel for cryogenic applications

-

Stainless Alloy Pipes: Austenitic (304H, 316H), Ferritic, Martensitic grades

-

-

By Manufacturing Process:

-

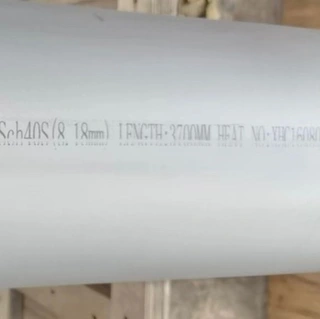

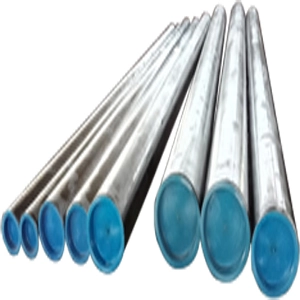

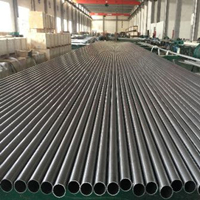

Seamless Alloy Pipes: Hot-extruded or cold-drawn for uniform microstructure

-

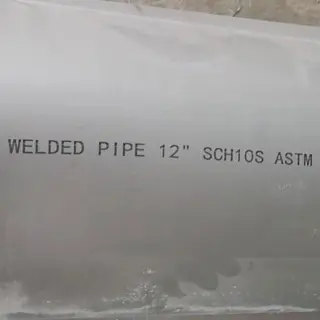

Welded Alloy Pipes: ERW, SAW, or laser-welded with full heat treatment

-

Clad/Bimetallic Pipes: Carbon steel base with alloy inner layer for cost optimization

-

Extruded Pipes: For complex nickel and titanium alloys

-

-

By Application Specifications:

-

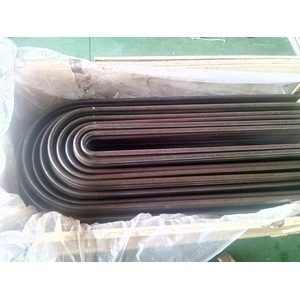

Power Generation: Boiler tubes, superheater/reheater tubes, steam lines (ASME SA213)

-

Oil & Gas: Downhole tubing, flowlines, risers in sour service (NACE MR0175)

-

Chemical Processing: Reactor coils, heat exchanger tubes, process piping

-

Petrochemical: Cracker tubes, reformer tubes, ethylene furnace tubes

-

Aerospace & Defense: Hydraulic lines, structural components

-

Nuclear Industry: Primary coolant pipes, steam generator tubes

-

-

By Standards & Certifications:

-

ASTM Standards: A213, A335, A312, A790, A928

-

ASME Standards: SA213, SA335, SA312

-

API Specifications: 5CT, 5L for OCTG and line pipe applications

-

EN Standards: EN 10216-2, EN 10217-5

-

NACE Compliance: MR0175/ISO 15156 for sour service

-

Technology & Innovation Trends

-

Advanced Metallurgy:

-

Micro-alloying with Nb, V, Ti for grain refinement

-

Clean steel technology with ultra-low sulfur and phosphorus

-

Thermo-mechanical controlled processing (TMCP) for enhanced properties

-

-

Manufacturing Innovations:

-

Rotary forging and pilger mill processes for seamless pipes

-

Laser and plasma welding for precision welded pipes

-

In-line heat treatment systems for consistent microstructure

-

Automated ultrasonic and eddy current testing

-

-

Digital Transformation:

-

IoT-enabled pipe tracking with embedded RFID

-

Digital twins for corrosion and remaining life prediction

-

AI-based non-destructive testing (NDT) analysis

-

Blockchain for material traceability and certification

-

-

Sustainability Focus:

-

Recycled alloy content optimization

-

Energy-efficient heat treatment technologies

-

Lightweight designs for transportation efficiency

-

Life extension technologies through coatings and cladding

-

Global Market Drivers

-

Power plant efficiency improvements driving demand for high-temperature alloys

-

Deepwater and sour oil & gas field developments

-

Chemical industry expansion in corrosive service applications

-

Nuclear power plant construction and life extension programs

-

Aerospace industry growth and lightweight material requirements

-

Hydrogen economy infrastructure development

-

Carbon capture, utilization, and storage (CCUS) projects

-

Strict safety and environmental regulations

Major Players & Value Chain

-

Global Specialists: Vallourec, Tenaris, TMK, Nippon Steel, Sandvik

-

Alloy Experts: Special Metals, Haynes International, Carpenter Technology

-

Regional Leaders: China (Baosteel, TPCO), India (Jindal SAW), Europe (Dalmine)

-

Value Chain: Raw material mining → alloy production → pipe manufacturing → heat treatment → testing/certification → distribution → EPC contractors → end-users

Challenges & Opportunities

-

Challenges:

-

High raw material and manufacturing costs

-

Technical complexity in welding and fabrication

-

Long lead times for specialized alloys

-

Competition from alternative materials (composites, ceramics)

-

Skilled labor shortage in metallurgy and welding

-

-

Opportunities:

-

Ultra-supercritical power plant developments

-

Hydrogen transportation and storage solutions

-

Deepwater and Arctic oil & gas exploration

-

Nuclear fusion reactor material development

-

Digital services for pipe integrity management

-

Circular economy through alloy recycling

-