1. Industry Definition & Scope

The Packaging Labels Industry is a specialized segment within the broader packaging and printing sectors, dedicated to the design, production, and application of functional and decorative labels adhered to various products and packaging. Labels serve as the critical interface between a product and its consumer, conveying essential information (ingredients, usage), ensuring compliance (regulatory, safety), enabling supply chain operations (tracking, scanning), and providing powerful brand identification and marketing.

2. Major Product Categories

-

By Primary Function & Application:

-

Product Labels (Primary Labels): Applied directly to the product container (e.g., beverage bottle, shampoo bottle, food can). Focus on branding, ingredients, and net weight.

-

Packaging Labels (Secondary Labels): Applied to the outer packaging (e.g., corrugated box, folding carton). Often used for shipping information, barcodes, and handling instructions.

-

Variable Data & Barcode Labels: Contain unique information such as serial numbers, QR codes, batch/lot codes, expiry dates. Critical for traceability and inventory management.

-

Security & Authentication Labels: Feature holograms, tamper-evident seals, RFID tags, or specialty inks to prevent counterfeiting and ensure product integrity (pharmaceuticals, electronics, luxury goods).

-

Promotional & Interactive Labels: Include peel-off coupons, augmented reality (AR) triggers, NFC tags for consumer engagement.

-

-

By Label Construction & Material:

-

Paper Labels: Economical, versatile, used for dry products (boxes, cans).

-

Film Labels (Plastic Labels): Made from PP, PE, PET, vinyl. Offer moisture resistance, flexibility, and clarity, essential for beverage bottles, personal care products, and frozen foods.

-

Foil Labels: Provide a premium, metallic appearance for luxury branding.

-

Clear ("No-Look") Labels: Create a "printed directly on container" aesthetic for premium products.

-

Specialty Materials: Tyvek (durable), fabric, and biodegradable/compostable films.

-

-

By Adhesive Type:

-

Permanent Adhesive: For a long-lasting bond.

-

Removable/Repositionable Adhesive: Allows for label removal without residue.

-

Freezer-Grade Adhesive: Performs in cold, wet environments.

-

3. Industry Chain Structure

Upstream:

-

Raw Material Suppliers: Manufacturers of label stocks (paper, film, foil), adhesives, release liners (the backing paper), and printing inks (including specialty UV, water-based, and security inks).

-

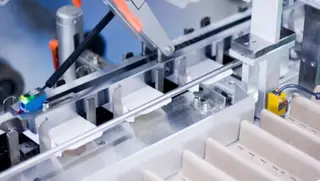

Equipment Manufacturers: Suppliers of label printing presses (digital, flexo, letterpress), die-cutting machines, applicators (automated labeling machines), and inspection systems.

Midstream (Label Converters):

-

Label Manufacturers/Converters: The core of the industry. They purchase raw materials, print, die-cut, and convert them into finished labels. They range from large multinationals to small regional shops.

-

Specialized Converters: Focus on specific niches like pharmaceutical labels, prime labels for food & beverage, or industrial durable labels.

-

-

Design & Prepress Services: Creating the label artwork and preparing files for plate-making (for flexo) or digital printing.

Downstream:

-

End-User Industries (Brand Owners):

-

Food & Beverage (Largest Segment)

-

Pharmaceutical & Healthcare

-

Personal Care & Cosmetics

-

Chemicals & Industrial Products

-

Wine & Spirits

-

E-commerce & Logistics

-

-

Label Applicators: Companies or in-house lines that apply labels to products/packaging at high speeds.

-

Packaging Machinery Integrators: Companies that design production lines, integrating labeling stations.

-

Consumers & Regulatory Bodies: The final interaction point and the source of compliance requirements.

4. Key Market Dynamics & Characteristics

-

Non-Discretionary Demand: Labels are mandatory for almost all consumer and industrial products, providing steady demand despite economic cycles.

-

Stringent Regulatory Environment: Heavily regulated by agencies like the FDA (nutrition facts, drug facts), FTC, and EU regulations (ingredient listing, allergen warnings). Compliance is non-negotiable.

-

Short-Run & Just-in-Time Trend: Driven by SKU proliferation, limited editions, and agile marketing, increasing demand for digital printing's flexibility.

-

High Importance of Adhesive Performance: Label failure (falling off, wrinkling, not sticking in cold/wet conditions) is a critical quality defect, making adhesive science crucial.

-

Brand-Centric Innovation: Labels are a primary vehicle for brand differentiation through unique shapes, materials, textures, and finishes.

5. Development Trends

-

Digital Printing Dominance for Short Runs:

-

High adoption of digital inkjet and electrophotographic presses enabling cost-effective, quick-turnaround production of customized and variable data labels.

-

Web-to-print platforms for easy online ordering and proofing.

-

-

Sustainability & Circularity Focus:

-

Development of linerless label technologies to eliminate silicone-coated backing paper waste.

-

Use of recycled and bio-based label materials and compostable adhesives.

-

Design for Recycling: Labels that are easily separable from containers to improve packaging recyclability.

-

-

Smart & Connected Labels:

-

Integration of QR codes, NFC, and RFID for supply chain visibility, anti-counterfeiting, and direct consumer engagement (accessing recipes, brand stories, authenticity verification).

-

Freshness indicator labels using color-changing inks for food quality monitoring.

-

-

Enhanced Visual & Tactile Appeal:

-

Use of specialty inks (metallic, fluorescent, tactile), embossing, foil stamping, and textured substrates to create premium shelf impact.

-

Extended Color Gamut (ECG) printing for more vibrant, consistent brand colors.

-

-

Automation & Intelligent Finishing:

-

High-speed digital finishing lines with integrated die-cutting, laminating, and inspection for complex labels.

-

Vision inspection systems using AI to detect print defects and ensure 100% accuracy on variable data (like barcodes and expiry dates).

-

6. Major Challenges & Opportunities

Challenges:

-

Raw Material Cost Volatility: Prices for paper, film resins, and adhesives are subject to market fluctuations.

-

Intense Price Competition: Especially for standard, high-volume commodity labels (e.g., simple prime labels for canned goods).

-

Meeting Complex Regulatory Requirements: Navigating and complying with ever-changing global and industry-specific regulations is costly and complex.

-

Adhesive & Application Failures: Risk of product recalls or brand damage if labels fail under specific conditions (e.g., condensation on cold bottles, chemical exposure).

-

Talent Gap: Need for skilled operators for advanced digital and hybrid printing/finishing equipment.

Opportunities:

-

Growth in Pharmaceutics & Healthcare: Increasing demand for complex, compliant, and anti-tamper labels, especially with serialization requirements.

-

Craft & Premium Brand Proliferation: The rise of craft beverages, artisanal foods, and niche cosmetics drives demand for small-batch, high-design labels where digital printing excels.

-

E-commerce & Direct-to-Consumer (DTC) Growth: Brands need distinctive labels that stand out in mailboxes and support unboxing experiences.

-

Smart Label Integration: Providing value-added services by integrating track-and-trace, authentication, and interactive features into labels.

-

Sustainability Leadership: Offering innovative, sustainable label solutions (linerless, recyclable, compostable) as a key differentiator for eco-conscious brands.