Industry Definition & Scope

The nuts industry involves the manufacturing, distribution, and application of internally threaded fastening components designed to mate with bolts, screws, or studs to create secure mechanical joints. As essential elements in assembly and construction, nuts ensure structural integrity, vibration resistance, and load distribution across virtually all industrial sectors, from microelectronics to heavy infrastructure.

Key Product Categories

-

By Product Type:

-

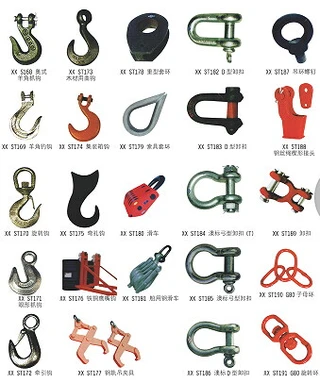

Hex Nuts: Standard six-sided nuts (ANSI/ASME B18.2.2)

-

Lock Nuts: Nylon insert, deformed thread, or all-metal locking designs

-

Flange Nuts: Integrated washer-like flange for load distribution

-

Wing Nuts: Hand-tightenable with wing-like projections

-

Cap Nuts: Decorative dome-shaped covers for exposed threads

-

Square Nuts: Four-sided design for wrenching in constrained spaces

-

Coupling Nuts: Extended length for connecting two threaded rods

-

Specialty Nuts: T-slot, cage, slotted, and weld nuts

-

-

By Material Grades:

-

Carbon Steel: Grade 2, 5, 8 (ASTM A563)

-

Alloy Steel: Heat-treated for high strength (ASTM A194 Gr. 2H/2HM)

-

Stainless Steel: 304, 316, 410 (ASTM A194 Gr. 8/8M)

-

Non-Ferrous: Brass, bronze, aluminum, silicon bronze

-

High-Temperature Alloys: Inconel, Monel, Hastelloy

-

Polymer/Nylon: Electrical insulation and corrosion resistance

-

-

By Thread Specifications:

-

Metric Threads: ISO standards (M3-M100 coarse/fine pitch)

-

Unified Threads: UNC/UNF (Imperial system)

-

Left-Hand Threads: Reverse rotation applications

-

Self-Locking Threads: Prevailing torque designs

-

-

By Application Standards:

-

Structural Bolting: ASTM A563 for construction applications

-

Pressure Equipment: ASTM A194 for high-pressure/temperature service

-

Aerospace: NAS, MS, AN standards

-

Automotive: ISO 4032, DIN 934, SAE J995

-

Railway: EN 15048, AREMA standards

-

Electrical: UL recognized components

-

Technology & Innovation Trends

-

Advanced Manufacturing:

-

Multi-station cold forming with progressive dies

-

Automated thread rolling with CNC precision

-

Robotic heat treatment and plating lines

-

Vision inspection systems for 100% quality verification

-

-

Material Science Innovations:

-

Micro-alloyed steels for enhanced strength-to-weight ratio

-

Nanocomposite coatings for corrosion and wear resistance

-

Shape memory alloys for temperature-responsive locking

-

Biodegradable polymers for temporary fastening applications

-

-

Smart Fastening Technology:

-

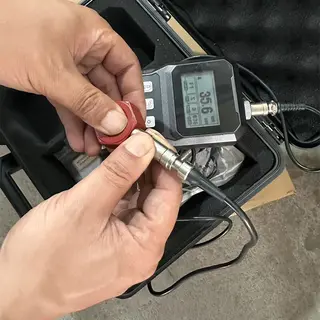

RFID-embedded nuts for torque and tension monitoring

-

IoT-connected smart nuts with wireless load sensing

-

Color-changing indicators for proper installation verification

-

Self-loosening detection systems

-

-

Sustainability & Efficiency:

-

Recycled steel content optimization

-

Water-based and chromium-free plating processes

-

Energy-efficient manufacturing with waste heat recovery

-

Circular economy models through nut reconditioning

-

Global Market Drivers

-

Global infrastructure development and urbanization

-

Automotive production and electric vehicle manufacturing

-

Renewable energy installation (wind turbines, solar farms)

-

Aerospace and defense sector growth

-

Industrial machinery and equipment manufacturing

-

Electronics and consumer goods assembly

-

Maintenance, repair, and operations (MRO) activities

-

Replacement demand in aging structures and equipment

Major Players & Value Chain

-

Global Leaders: Würth Group, Fastenal, ITW, Bossard, KAMAX

-

Specialty Manufacturers: Nucor Fastener, Infasco, Bulten, Acument Global

-

Regional Leaders: China (Zhuji, Yongnian clusters), India (Ludhiana, Mumbai)

-

Automotive Specialists: TRW, SFS Group, Penn Engineering

-

Value Chain: Wire rod production → cold heading → threading → heat treatment → coating/plating → quality testing → packaging → distribution → OEM/MRO → end-use

Challenges & Opportunities

-

Challenges:

-

Raw material price volatility (steel, nickel, copper)

-

Intense competition from low-cost producers

-

Counterfeit and substandard products in some markets

-

Technical complexity in extreme environment applications

-

Environmental compliance costs

-

-

Opportunities:

-

Smart nut technology for structural health monitoring

-

Lightweight materials for automotive and aerospace

-

Digital supply chain and inventory management solutions

-

Customization for specialized industrial applications

-

Emerging market industrialization

-

Aftermarket and maintenance service expansion

-

Sustainable manufacturing and green certifications

-