Industry Definition & Scope

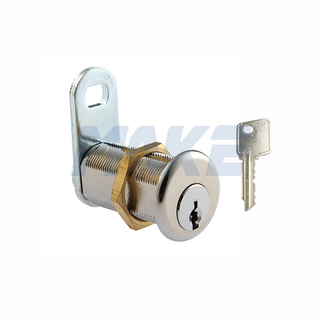

The cam locks industry specializes in the design, manufacturing, and distribution of specialized locking mechanisms featuring a rotating cam (typically 90°-180°) that engages with a strike plate or directly with the structure being secured. These compact, versatile locks are widely used in furniture, cabinets, enclosures, vending machines, industrial equipment, and various access control applications where space constraints, ease of installation, and cost-effectiveness are critical considerations.

Key Product Categories

-

By Mechanism Type:

-

Single-Bitted Cam Locks: Standard key-operated with simple pin tumbler mechanisms

-

Double-Bitted Cam Locks: Higher security with dual-sided keyways

-

Tubular Cam Locks: Circular keyways offering enhanced pick resistance

-

Barrel Cam Locks: Cylindrical design for specific mounting requirements

-

Electronic Cam Locks: Keypad, RFID, or biometric activation with electric cam rotation

-

-

By Cam Configuration:

-

Standard Cams: Fixed position or reversible (left/right hand)

-

Adjustable Cams: Variable throw length or adjustable rotation angle

-

Special Cams: Offset, folding, or customized shapes for unique applications

-

Spring-Return Cams: Self-retracting for automatic latching

-

-

By Application Area:

-

Furniture & Cabinetry: File cabinets, lockers, display cases, office furniture

-

Industrial & Equipment: Control panels, machine guards, tool chests, junction boxes

-

Retail & Vending: Cash drawers, vending machines, kiosks, POS systems

-

Automotive & Transportation: Glove compartments, storage compartments, utility vehicles

-

Electronics & IT: Server racks, network cabinets, data center security

-

Medical & Laboratory: Medicine cabinets, equipment enclosures, specimen storage

-

-

By Security Level:

-

Basic Security: Standard pin tumbler mechanisms for low-risk applications

-

Medium Security: Anti-pick pins, restricted keyways, reinforced construction

-

High Security: Drill-resistant materials, mushroom/spool pins, key control systems

-

UL/CEN Certified: Meeting specific industry standards for safety and reliability

-

Technology & Innovation Trends

-

Advanced Security Features:

-

Anti-drill hard plates and rotating ball bearing mechanisms

-

Sidebar and magnetic interaction systems for enhanced pick resistance

-

Laser-cut keys with complex bitting patterns

-

Key control systems with registered keyways and restricted duplication

-

-

Electronic & Smart Integration:

-

RFID and NFC-enabled cam locks for access logging

-

Wireless connectivity for remote management and audit trails

-

Battery-powered electronic cam locks with low-power modes

-

Integration with building management and IoT security systems

-

-

Material & Manufacturing Innovations:

-

Zinc alloy die casting with corrosion-resistant coatings

-

Stainless steel construction for harsh environments

-

PVD (Physical Vapor Deposition) coatings for enhanced durability

-

Precision CNC machining for tight tolerances and smooth operation

-

-

Design & Usability Improvements:

-

Tool-less installation and adjustment systems

-

Universal mounting kits for diverse applications

-

Ergonomic key designs and easy-grip heads

-

Color-coded systems for visual management and organization

-

Global Market Drivers

-

Growth in office furniture and commercial cabinetry markets

-

Increasing security requirements for retail and vending equipment

-

Expansion of data centers and IT infrastructure requiring rack security

-

Rising demand for industrial equipment protection and safety compliance

-

Growth in automotive and transportation storage solutions

-

DIY and professional installation trends in furniture security

-

Replacement and upgrade cycles in existing installations

-

Global standardization of security requirements in various industries

Major Players & Value Chain

-

Global Specialists: ABUS, COMPX (Timberline), Southco, CISA, JPM

-

Industrial Focus: ASSA ABLOY (Viking), Hafele, Lowe & Fletcher

-

Electronics Integration: Digilock, Locinox, E-Lock

-

Regional Manufacturers: Chinese (Zhejiang, Guangdong hubs), Indian manufacturers

-

Value Chain: Raw materials → component manufacturing → assembly → key cutting systems → distribution → OEM integration → aftermarket/retail

Challenges & Opportunities

-

Challenges:

-

Price competition from low-cost manufacturers

-

Standardization issues across different regions and industries

-

Key management complexities in large installations

-

Rapid technological changes requiring continuous R&D investment

-

Counterfeit products affecting brand reputation and security

-

-

Opportunities:

-

Smart lock integration in furniture and cabinetry

-

Growth in data center and IT infrastructure security

-

Customization for specialized industrial applications

-

Emerging markets with growing commercial and industrial sectors

-

Service models including key management and access control solutions

-

Sustainable manufacturing and recyclable material initiatives

-

Integration with digital twin and asset management systems

-