DIN 3352 Wedge Gate Valve, ASTM A216 WCB, DN150, PN25, BB

Key Specifications / Features

The DIN 3352 Wedge Gate Valve Plant offers a robust and reliable wedge gate valve designed for industrial applications. This valve is constructed from ASTM A216 WCB cast carbon steel. With a nominal diameter of DN150 (6 inches) and a pressure rating of PN25 (Class 300 LB), it is suitable for a wide range of fluid control needs. The bolted bonnet design provides easy maintenance access, while the RF (Raised Face) flanged ends ensure secure connections.

Detail Information

Product Name: DIN 3352 Wedge Gate Valve, Bolted Bonnet

Design Standard: DIN 3352

Body Material: ASTM A216 WCB

Size: DN150, 6 Inch

Pressure: PN25, Class 300 LB

End Connection: RF Flanged

Operation: Handwheel

Medium: Water, Oil, Gas, etc

Temperature Range: -29°C to 595°C

The Wedge Gate Valves are designed and manufactured to ensure that the leakage of volatile organic compounds (VOCs) is less than 100 parts per million (ppm). Extensive baseline laboratory testing, including both static and cycle tests, has been conducted to establish the critical design parameters necessary for achieving low-emission sealing in the stem packing seal area and the bonnet gasket sealing area. An in-house testing procedure has been developed and is periodically performed to ensure that the standard product design and manufacturing criteria consistently result in the Wedge Gate Valve meeting a maximum of 100 ppm VOC leakage before shipment.

Technical Specification

» Type: Wedge Gate Valve

» Nominal Diameter: DN50-DN1000

» Design Pressure: PN6-PN16

» Body/Bonnet/Wedge: Cast Steel (EN 1.0619), Stainless Steel (EN 1.4308; EN 1.4408), Alloy Steel EN 1.7335 (WC6)

» Stem: X20Cr13 or EN 1.4021, Stainless Steel (EN 1.4308; EN 1.4408)

» Seat: 13Cr, 18Cr, Stellite

» End Connections: RF Flange, Groove Flange, BW

» Operation: Handwheel, Bevel Gear, Electric, Pneumatic

» Structural Formation: BB-BG-OS & Y

» Design Standard: DIN 3352

» Face-to-Face Dimension: According to EN 558-1 15 (DIN 3202 F5 series)

» Flange Ends: DIN 2543 to 2547, EN 1092-1, GOST 12815, GOST 12819

» Butt Welded End: EN 12627

» Test & Inspection: DIN 3230

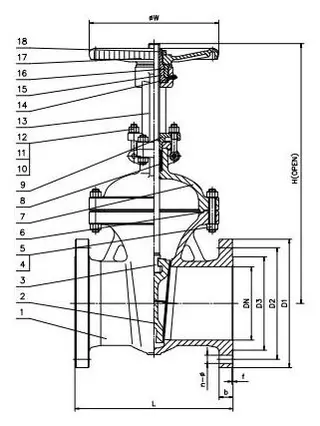

Structural Diagram

Product Features

» Anti-friction ball thrust bearing: Reduces friction between mating parts to ensure smooth operation

» Grub screw: Secures yoke nut in the bonnet

» Grease nipple: Supplies lubricant to the mating parts

» OS&Y, Outside Stem and Yoke

» Metal-sealed, Trim # 1, #5, #8, #10 and etc.

» Optional Locking Device or Stem Extension

» Optional Direct Mounting to ISO 5211

» Full Port