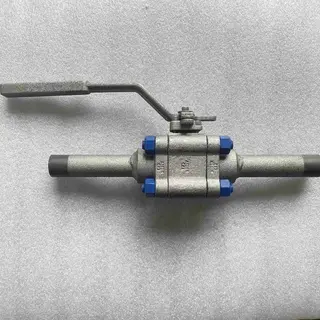

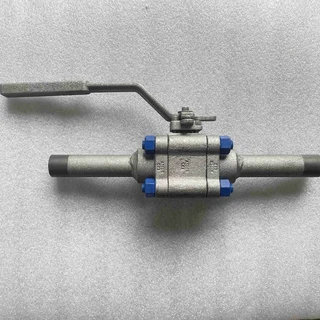

Three-piece Ball Valve, ASTM A182 F304L, 3/4 Inch, 600 LB

Key Specifications / Features

As a reputable Three-piece Ball Valve Fabricator, we take pride in presenting a premium solution for fluid control. Crafted with precision and adherence to industry standards, our valve is engineered for excellence. As a testament to quality, the valve is constructed from ASTM A182 F304L stainless steel, ensuring corrosion resistance and durability.

Request a quote

Detail Information

Size: 3/4 Inch, DN20

Pressure: Class 600 LB, PN100

Material: Stainless Steel ASTM A182 F304L

Standard: API 6D, ASME B16.34

Temperature Of Media: -29℃ To 120℃

Feature: Threaded Stainless Steel Ball Valve

Product Range

Size: 1/4 -4 Inch, DN8-DN100

Standard: API 608, GOST, DIN

Pressure: Class 150, 300, 600, 900, 1500, 2500 LB

Seat Material: PTFE, RPTFE, Devlon, Nylon, Peek

Connection: Thread BSP NPT, Female Thread/OD Size, threaded, Female, RF, RTJ, SW

| Technical data | |||||||

| Design | API 6D, ASME B16.34, ISO 14313, ISO 10423, ISO 17292 | ||||||

| Pressures range | ANSI 150-ANSI 2500, PN10-PN420 | ||||||

| Size range | DN15 (1/2")-DN1200 (48") | ||||||

| Body Material | Carbon Steel, Stainless Steel, Alloy Steel, Duplex Steel, etc. | ||||||

| NACE MR-01-75/NACE MR-01-03 Special Requirements | |||||||

| Face to face | API 6D, ASME B 16.10, EN 558, DIN3202 | ||||||

| Fanged RF, FF, RTJ Ends | ASME B16.5 ≤ DN600 (24") ASME B16.47 A ≥ DN650 (26") | ||||||

| BS 4504, DIN 2543-2545, EN1092 | |||||||

| Butt-Weld BW Ends | ASME B16.25, DIN 3239, BS 2080, EN 12627 | ||||||

| Temperature range | -29°C-425°C | ||||||

| Design feature | |||||||

| Construction | One, Two or Three piece body and Welded body | ||||||

| Port | Full bore and Reduced bore | ||||||

| Ball Type | Floating ball and fixed ball | ||||||

| Stem | Blowout-proof stem | ||||||

| Seat Sealing | Front-seat sealing, Back-seat sealing, bi-directional sealing | ||||||

| Valve Operation | Gear,pneumatic,Hydraulic,Electric actuators. | ||||||

| Bypasses, locking devices, extended stem, etc | |||||||

| Fire Safe | API 607, BS 6755, ISO 10497-5 | ||||||

| Other design | Anti-static design, automatic pressure relief design, emergency grease injection design, drain valve, anti-corrosion design, anti-sulfur design, etc | ||||||

| Inspection and Test | |||||||

| Visual Inspection | MSS SP-55 | ||||||

| Material Inspection |

|

||||||

| Dimension inspection | According to drawings | ||||||

| Valve Inspection and Test | API 598,DIN 3230,EN 12266,BS 5146 | ||||||

Send your message to this supplier

FAQs

While circular knitting machines are generally safe to use, it is important to follow the manufacturer’s instructions and take necessary precautions. This may include wearing protective gloves and avoiding loose clothing near the machine.