Steam Jacketed Safety Valve, API 526, A351 CF8, DN50, PN16

Key Specifications / Features

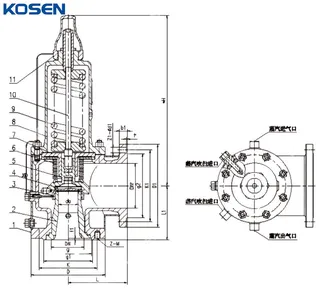

The Steam Jacketed Safety Valve, designed with balanced bellows and built to API 526 standards, features a stainless steel ASTM A351 CF8 body for strength and corrosion resistance. With a 2-inch (DN50) size, it supports PN16 and Class 150 LB pressure ratings, and comes with RF flanged ends for easy installation. Ideal for steam applications, this safety valve ensures reliable pressure relief, maintaining system integrity and safety under high-pressure conditions.

Detail Information

Product Name: Steam Jacketed Balanced Bellows Safety Valve

Design Standard: API 526

Body Material: ASTM A351 CF8

Size: DN50, 2 Inch

Pressure: PN16, Class 150 LB

End Connection: RF Flanged

The Safety Valve is specifically designed for use in polyester, ethylene, urea, and other industrial processes. This safety valve is equipped with an Insulation Jacket and a steam purge joint to ensure safe and reliable operation of the system.

The discharge area of the safety valve is calculated based on the cylindrical or conical surface formed between the valve disc and the valve seat. This design makes it particularly suitable for applications with small discharge capacities, large back pressures, and stable system pressures. The Safety Valve provides a reliable solution for maintaining system safety and efficiency in demanding industrial environments.

Technical Specifications

» Normal Size Range: 1/2-12 Inch (DN15-DN300)

» Normal Pressure Rating: Class 150-300 LB (PN10-PN40)

» Materials: Carbon Steel, Stainless Steel, Alloy Steel, Duplex, or Other Specials

» Design and Manufacture: GB/T 12243-1989, API RP 520, 521, API 526, API 527

» Face to Face (End to End): GB/T 14087, JB/T 6441, JB/T 2203, JB/T 9624, JB/T 53170

» Flanged Connection: ASME B16.5, DIN 2543 to 2545, EN 12627

» Test and Inspection: API 598, DIN 3230, MSS SP-117

» Ends Connections: RF Flange

» Working medium: used for polyester, ethylene, urea

Main Parts and Materials

|

No |

Name of Parts |

Carbon steel |

Stainless steel |

Stainless steel |

|

1 |

Body |

A216 WCB |

A351 CF8 |

A351 CF8M |

|

2 |

Nozzle |

SS 304 |

SS 304 |

SS 316 |

|

3 |

Adjusting Ring |

SS 304 |

SS 304 |

SS 316 |

|

4 |

Disc |

SS 304 |

SS 304 |

SS 316 |

|

5 |

Disc Holder |

SS 304 |

SS 304 |

SS 304 |

|

6 |

Bellows |

SS 316L |

SS 316L |

SS 316L |

|

7 |

Guide Sleeve |

50CrVA |

50CrVA |

50CrVA |

|

8 |

Bonnet |

ZG230-450 |

SS 304 |

SS 316 |

|

9 |

Spring |

50CrVA |

50CrVA+Coated Teflon |

|

|

10 |

Stem |

2Cr13 |

SS 304 |

SS 316 |

|

11 |

Cap |

ZG230-450 |

SS 304 |

SS 316 |

|

12 |

Sealing surface |

Overlay STL |

Overlay STL |

Overlay STL |

Send your message to this supplier

FAQs

What is a Non-Rising Stem Gate Valve?

A valve where the stem does not move vertically but rotates internally to raise or lower the gate. This design is ideal for installations with limited vertical space.

How Does a Non-Rising Stem Gate Valve Work?

The handwheel turns the stem, which in turn moves the gate up or down inside the valve body without changing the external height of the stem.

How Does a Rising Stem Gate Valve Work?

The handwheel lifts the stem and gate together, providing a visual indication of whether the valve is open or closed.

Which Valve Should I Choose?

Use a rising stem valve for above-ground applications where visibility and ease of maintenance are important.

Use a non-rising stem valve for underground or space-limited installations.

Conclusion

The choice between rising stem and non-rising stem gate valves depends on your specific application needs. For clear valve status indication and easy maintenance, go with a rising stem valve. For compact installations, a non-rising stem valve is the better option.