ASTM A694 F60 Ball Valve, API 6A, 3000 PSI, 17-4PH Trim, RTJ

Key Specifications / Features

As a leading ASTM A694 F60 ball valve manufacturer in China, we offer high-performance valves designed to meet API 6A standards. Our 3-1/16 inch ball valves are rated for 3000 PSI and feature a durable ASTM A694 F60 body for reliable operation in demanding environments. Available with either soft or metal seats, these valves are suitable for various service conditions. Equipped with precision-engineered 17-4PH trim and RTJ end connections for secure sealing, they also feature gear operation for smooth, controlled handling. Ideal for oil and gas applications requiring strength, performance, and long-term reliability.

Detail Information

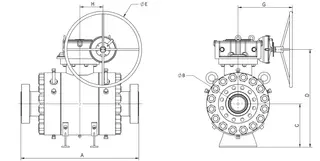

Valve Description:

181104025 API 6A Ball Valve

Design Standard: API 6A

Nominal Size: 1-13/16 Inch to 11 Inch

Nominal Class: 2000 PSI-15000 PSI

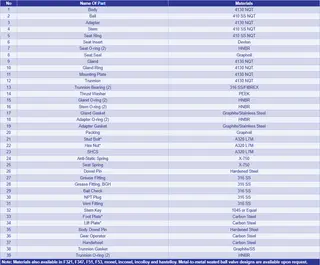

Body Material: AISI 4130/ASTM A694 F60/ASTM A694 F65

Trim Material: AISI 4140/F51/17-4PH/Inconel Trim

Bore Type: Full Bore or Reduced Bore

End Connection: RTJ, BW, and Hub

Operation: Lever/Gear/Bare Shaft

Structure: Bolted Bonnet

Seat Insert: PEEK or Hardfaced

Face to Face: ASME B16.10/MFG'S

Test and Inspection: API 6A

Key Features: Double Block&Bleed(DBB), Anti-static Device, Fire Safe, Anti-Blowout Stem, Emergency sealant injection, Low Emission(Optional), DIB (Optional), full welded bonnet, SPE and DPE Seat Design (SPE x SPE, DIB-1, DIB-2), Bubble-Tight Shut-Off

Material Class: AA, BB, CC, DD, EE, FF, HH

Temperature Class: L, N, P, S, T, U, V, X, Y

Specification: PSL1 - PSL3G

Performance: PR1, PR2

Product Range:

Body Material: Carbon Steel, Stainless Steel, Alloy Steel

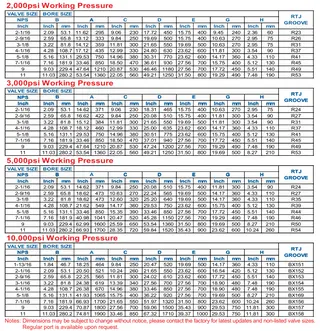

Normal Diameter: 1-13/16 Inch - 11 Inch

Pressure Range: 2000 PSI - 15000 PSI

End Connection: RF, RTJ, BW, HUB

Working Temperature: -26°C - +150°C

Operation: Manual(lever, gear), Pneumatic Actuator, Motor Actuator

Design Features:

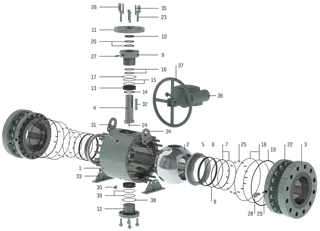

Bolted body with 2-piece and 3-piece construction

Available with metal-to-metal or soft seat options

Anti-blowout stem design for enhanced safety

Double block and bleed capability

SPE and DPE seat configurations (SPE x SPE, DIB-1, DIB-2)

Integrated anti-static devices

Ensures bubble-tight shutoff for reliable sealing