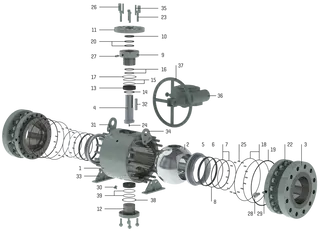

AISI 4130 Ball Valves, API 6A, 2-1/16 Inches, 3000 PSI, BW

Key Specifications / Features

We are a ball valve factory in China specializing in 3000 PSI valves designed to API 6A standards. This 2-1/16 inch ball valve features a robust AISI 4130 forged steel body and butt-weld (BW) end connections for secure pipeline integration. The valve offers seat options in PEEK, TCC, or STL to suit various service conditions. With high-performance trim materials such as 17-4PH and Inconel, it ensures excellent corrosion and wear resistance. Operated by lever for manual control, it is ideal for demanding oil and gas applications requiring durability and reliability.

Detail Information

Valve Description:

181104023 API 6A Ball Valve

Design Standard: API 6A

Structure: Bolted Bonnet

Nominal Size: 1-13/16 Inch to 11 Inch

Nominal Class: 2000 PSI-15000 PSI

Seat Insert: PEEK or Hardfaced

Face to Face: ASME B16.10/MFG'S

Bore Type: Full Bore or Reduced Bore

End Connection: RTJ, BW, and Hub

Operation: Lever/Gear/Bare Shaft

Body Material: AISI 4130/ASTM A694 F60/ASTM A694 F65

Trim Material: AISI 4140/F51/17-4PH/Inconel Trim

Test and Inspection: API 6A

Key Features: Double Block&Bleed(DBB), Anti-static Device, Fire Safe, Anti-Blowout Stem, Emergency sealant injection, Low Emission(Optional), DIB (Optional), full welded bonnet, SPE and DPE Seat Design (SPE x SPE, DIB-1, DIB-2), Bubble-Tight Shut-Off

Material Class: AA, BB, CC, DD, EE, FF, HH

Temperature Class: L, N, P, S, T, U, V, X, Y

Specification: PSL1 - PSL3G

Performance: PR1, PR2

Product Range:

Body Material: Carbon Steel, Stainless Steel, Alloy Steel

Normal Diameter: 1-13/16 Inch - 11 Inch

Pressure Range: 2000 PSI - 15000 PSI

End Connection: RF, RTJ, BW, HUB

Working Temperature: -26°C - +150°C

Operation: Manual(lever, gear), Pneumatic Actuator, Motor Actuator

Design Features:

Bolted body with 2-piece and 3-piece construction

Double block and bleed capability

SPE and DPE seat configurations (SPE x SPE, DIB-1, DIB-2)

Available with metal-to-metal or soft seat options

Anti-blowout stem design for enhanced safety

Integrated anti-static devices

Ensures bubble-tight shutoff for reliable sealing