Industry Definition & Scope

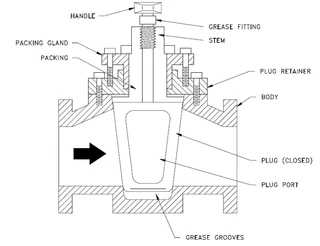

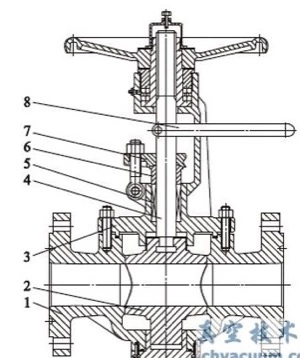

The plug valves industry encompasses the design, manufacturing, and application of quarter-turn valves that use a cylindrical or conical plug with a through-port to control fluid flow. Characterized by straight-through flow, minimal pressure drop, and self-cleaning action, plug valves are versatile shut-off and isolation devices particularly suited for abrasive, viscous, and slurry media in demanding industrial applications.

Key Product Categories

-

By Design Configuration:

-

Lubricated Plug Valves: Seal maintained by injected lubricant between plug and body (API 6D)

-

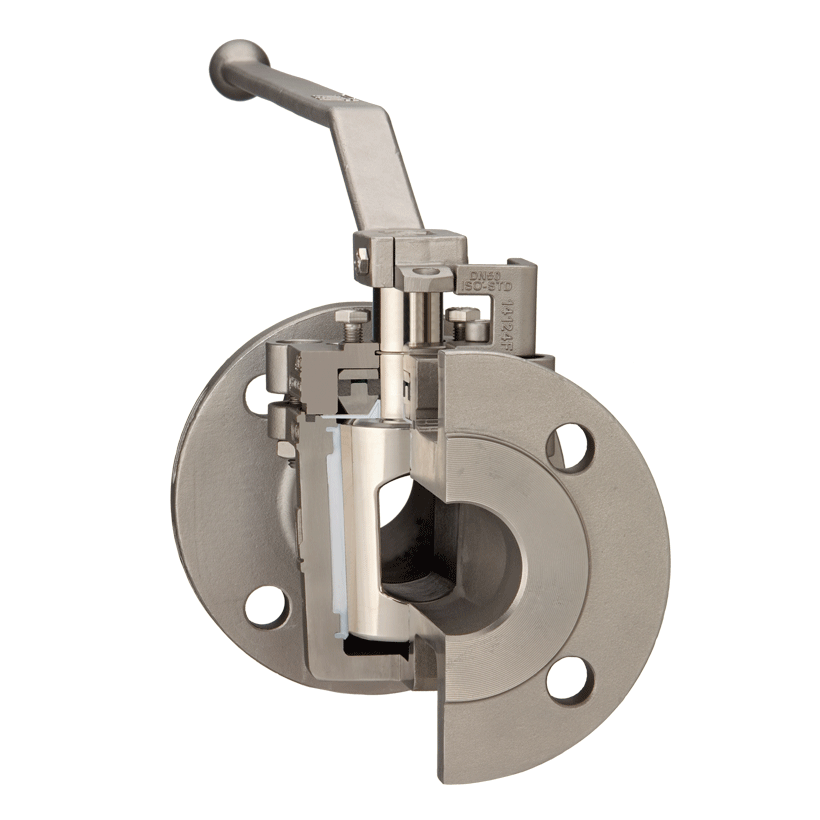

Non-Lubricated/Sleeved Plug Valves: PTFE or elastomeric sleeve provides sealing

-

Eccentric Plug Valves: Cam-action design with partial contact for longer life

-

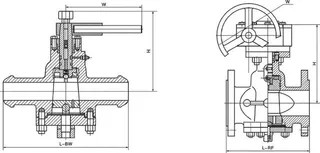

Multi-Port Plug Valves: 3-way, 4-way designs for flow diversion/mixing

-

Full-Bore/Regular-Port Designs: Port diameter matching or smaller than pipe ID

-

Jacketed Plug Valves: Steam/cooling jackets for temperature control

-

-

By Plug Design:

-

Cylindrical Plug: Straight-through design for minimal turbulence

-

Tapered Plug: Traditional design with tapered sealing surfaces

-

Rectangular Port Plug: High flow capacity for gas applications

-

V-Port Plug: Precise throttling and control capabilities

-

Fire-Safe Plug: Metal-to-metal secondary sealing (API 6FA/607)

-

-

By Material Construction:

-

Body Materials: Carbon steel (A216 WCB), stainless steel (A351 CF8/CF8M), alloy steel, bronze, ductile iron

-

Plug Materials: 13% Cr SS, Stellite-faced, Monel, Inconel, ceramic-coated

-

Sleeve/Liner Materials: Reinforced PTFE, PEEK, Nylon, UHMWPE, elastomers

-

Lubricants: Specialized grease systems for sealing and corrosion protection

-

Stem Materials: 316SS, 17-4PH, Monel, Titanium

-

-

By Application Specifications:

-

Oil & Gas: Pipeline block valves, wellhead controls, pigging operations

-

Chemical Processing: Corrosive and abrasive media handling

-

Mining & Minerals: Slurry transportation, tailings lines

-

Water & Wastewater: Mud, sludge, and abrasive water applications

-

Power Generation: Fly ash handling, bottom ash systems

-

Marine: Ballast systems, tanker loading/unloading

-

Cement Industry: Raw meal, clinker, cement powder handling

-

Technology & Innovation Trends

-

Advanced Sealing Technology:

-

PTFE composite sleeves with improved wear resistance

-

Pressure-assisted sealing systems for higher pressure ratings

-

Fire-safe designs with automatic sealing upon elastomer failure

-

Cryogenic plug valves for LNG (-196°C) with special material treatment

-

-

Digital Integration:

-

Smart valve position indicators with wireless connectivity

-

Lubrication monitoring systems with automated alerts

-

IoT-enabled condition monitoring for predictive maintenance

-

Digital twins for flow optimization and wear prediction

-

-

Material Innovations:

-

Nanocomposite sleeve materials extending service life

-

Ceramic-coated plugs for extreme abrasion resistance

-

Corrosion-resistant alloys for sour service (H₂S environments)

-

High-temperature materials for thermal oil applications

-

-

Manufacturing Excellence:

-

Precision CNC machining for tight tolerance plug-body fit

-

Robotic plasma spray coating for consistent surface treatment

-

Automated assembly with laser alignment verification

-

Additive manufacturing for complex internal geometries

-

Global Market Drivers

-

Oil and gas pipeline construction and maintenance activities

-

Mining industry expansion and mineral processing growth

-

Chemical industry capacity additions and plant upgrades

-

Water infrastructure development for abrasive media handling

-

Power plant environmental control systems (FGD, ash handling)

-

Increasing adoption in challenging media applications

-

Replacement demand for outdated valve technologies

Major Players & Value Chain

-

Global Leaders: Flowserve, Emerson, Cameron, KITZ, Crane, Weir Group

-

Specialized Manufacturers: Xomox, DeZURIK, Georg Fischer, Clarkson

-

Regional Leaders: China (Zhejiang, Jiangsu clusters), India (Audco, L&T)

-

Lubrication Specialists: Sealweld, Jet-Lube, Superior Products

-

Value Chain: Raw material suppliers → component manufacturing → valve assembly → lubrication systems → testing/certification → distributors → system integrators → end-users

Challenges & Opportunities

-

Challenges:

-

Lubrication system maintenance requirements

-

High torque operation in larger sizes

-

Limited throttling capabilities compared to specialized control valves

-

Competitive pressure from ball valves in some applications

-

Technical skill gap in proper selection and maintenance

-

-

Opportunities:

-

Abrasive and slurry handling market expansion

-

Digital lubrication management services

-

Hydrogen and CCUS infrastructure development

-

Mining industry automation and remote operation

-

Aftermarket services: re-sleeving, refurbishment, retrofitting

-

Emerging market infrastructure projects in Asia and Africa

-

.jpg)

-320x321.webp)