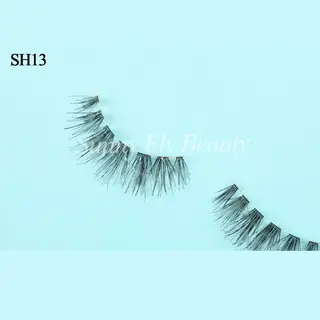

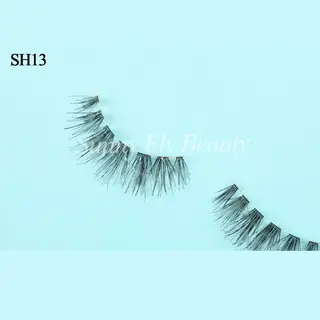

100% Hand-knotted False Eyelashes

Key Specifications / Features

Detail Information

Furthermore, as a professional wholesale eyelash vendor based in China, we provide custom private-label eyelash boxes at no extra cost. Our team assists in designing bespoke lash boxes, ensuring optimal packaging for your brand. With a track record of helping numerous clients establish their own eyelash brands, we've earned a reputation as China's premier eyelash wholesale vendor.

Send your message to this supplier

FAQs

At first, manufacturing low emission valves was pretty much the same for us as it was for other regular valve manufacturers in China. If we ran into problems like valves not passing tests or having leak rates that kept changing, we'd just try to get better packing materials from a different supplier. We didn't really stop to think about the bigger picture, like how the whole manufacturing process or the properties of the materials we were using might be causing the issues.

Over time, we figured out that the metal parts of the valves were pretty reliable, but we hadn't been paying enough attention to the non-metal parts that actually do the sealing. And those parts are super important for making sure the valves don't leak. So, back in 2008, we decided to focus on manufacturing low emission valves from start to finish.

First, we created a special team just for figuring out better ways to seal valves. They dug deep into how to make the seals work really well and how to build them. At the same time, we started working closely between the people who design the seals and the people who manufacture the valves. By tweaking the design of the seals and how we put the valves together, we made a system where everything works together perfectly. After that, we tested a bunch of different valves to see how well they sealed in all kinds of situations: different sizes, pressures, and temperatures. All the data we collected from these tests helped us keep improving our valves.

Now, when we manufacture a bunch of valves and check them randomly, they all meet the tough standards of API 624 and ISO 15848-1. We've gone from just following a process to really understanding and controlling the technology ourselves.