Y-Type Three-Way Ball Valve, A351 CF8, DN65, PN16, Pneumatic

Key Specifications / Features

Detail Information

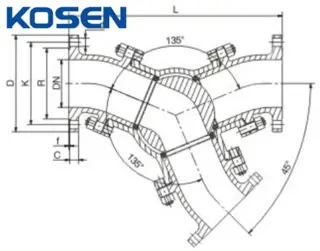

Product Name: Y-Type Three-Way Ball Valve, 135 Degree Port

Body Material: ASTM A351 CF8

Size: DN65, 2-1/2 Inch

Pressure: PN16, Class 150 LB

End Connection: Flanged

Operation: Pneumatic Actuator

The Y-type 135-degree 3-way ball valve is a versatile and reliable solution designed for efficient flow-switching in various industries, including automotive, power, and lithium battery manufacturing. This valve enables precise flow control and media distribution, making it an ideal choice for applications that require flow-switching capabilities in complex systems.

Working Process of Pneumatic Diverter Valve

A pneumatic diverter valve consists of an inlet, an outlet, and a mechanism (such as a rotating disc or sliding gate) that directs powder flow to the desired outlet. When activated, the valve adjusts the direction of the powder flow, allowing it to be diverted to a different location or process within the handling system. This functionality is crucial for controlling the distribution of powdered materials in various industrial applications.

Product Range

» Body Material: Stainless steel and carbon steel, offering high strength and durability.

» Body Style: Available in Y 120° or Y 135° port

» Sealing Material: PTFE, RPTFE, metal seal + STL for reliable sealing.

» Size Range: 2-12 Inch (DN50-DN300)

» Pressure Range: PN16, PN25, PN40, Class 150 LB, Class 300 LB

» Temperature Range: Up to 180°C

» Media Compatibility: Suitable for solid powders, liquid bulk, rubber, and other media.

» Control Options: Pneumatic actuator and electric actuator for precise flow control and management.

» Unique Design: The three-way Y-type 135-degree configuration ensures even flow distribution and facilitates medium switching without residue.

Main Connection Dimensions

|

DN |

L |

D |

K |

R |

C |

f |

n-d |

|

50 |

340 |

160/165 |

125 |

100 |

20 |

3 |

4-18 |

|

65 |

400 |

180/185 |

145 |

120 |

20 |

3 |

4-18 |

|

80 |

410 |

195/200 |

160 |

135 |

20 |

3 |

8-18 |

|

100 |

460 |

215/220 |

180 |

155 |

22 |

3 |

8-18 |

|

125 |

560 |

245/250 |

210 |

185 |

22 |

3 |

8-18 |

|

150 |

660 |

280/285 |

240 |

210 |

24 |

3 |

8-23 |

|

200 |

800 |

335/340 |

295 |

265 |

24 |

3 |

12-23 |

|

250 |

1030 |

405 |

355 |

320 |

30 |

3 |

12-25 |

|

300 |

1140 |

460 |

410 |

375 |

30 |

4 |

12-25 |

Send your message to this supplier

FAQs

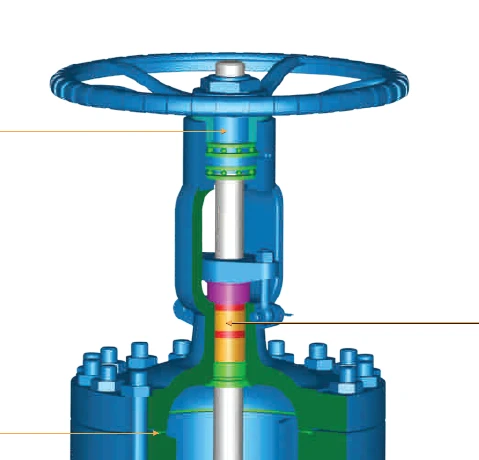

OS&Y stands for Outside Screw and Yoke. This design places the threaded stem outside the valve body, with the yoke supporting the stem. It allows users to visually verify whether the valve is open or closed by observing the stem’s position.

OS&Y gate valves are commonly used in fire protection systems, including sprinklers, hydrants, and standpipes, due to their reliability and clear open/close indication.

"Outside Screw and Yoke" (наружный винт и вилочный рычаг) — это конструкция клапана, при которой резьбовой шток (винт) находится снаружи корпуса клапана, а вилочный рычаг (йок) удерживает шток на месте. В отличие от других типов затворных клапанов, положение клапана OS&Y (открыт или закрыт) можно визуально определить по положению штока.

Затворные клапаны OS&Y широко используются в системах пожаротушения, системах гидрантов и стояковых системах. Их способность чётко показывать, открыт клапан или закрыт, делает их важными для безопасности и соблюдения нормативных требований.

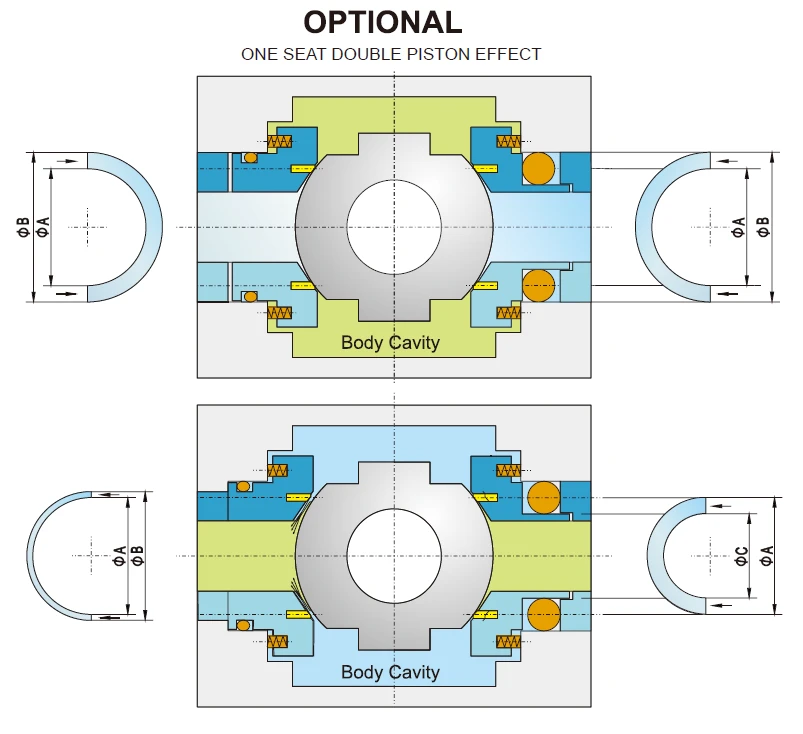

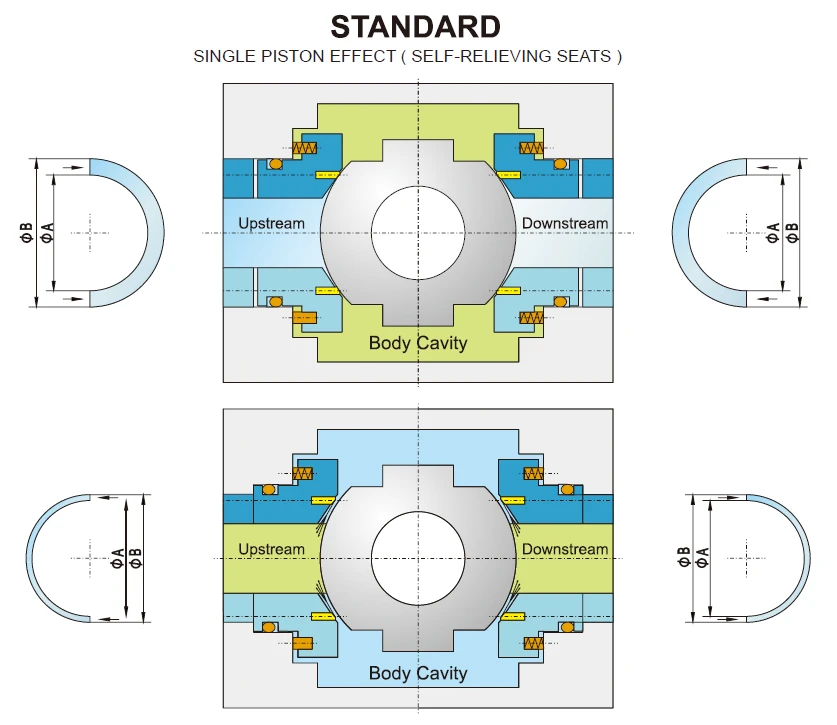

DBB - Doble Bloqueo y Purga (dos asientos de pistón simple)

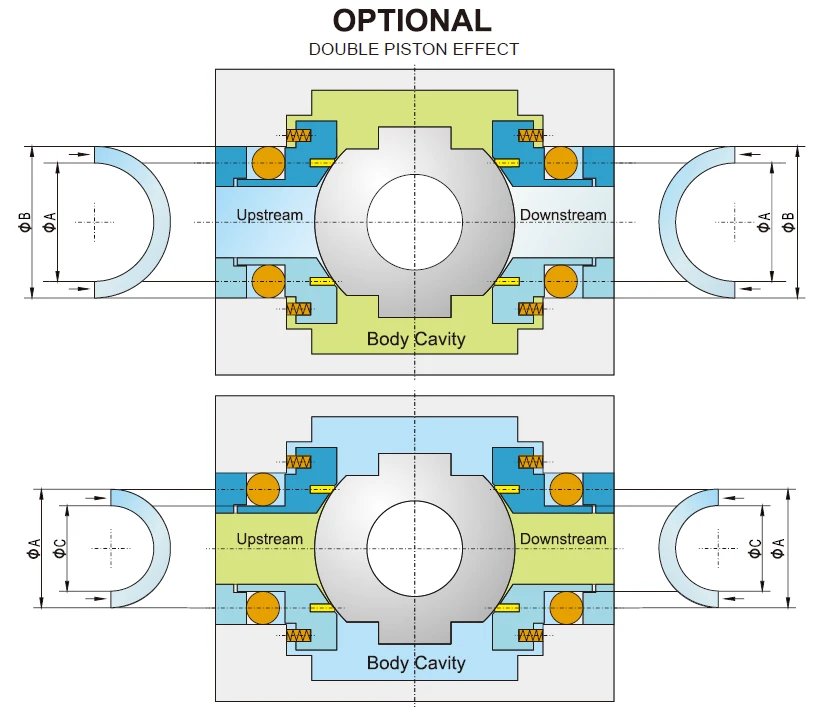

DIB-I (dos asientos de pistón doble)

DIB-II (un asiento de pistón doble y un asiento de pistón simple)