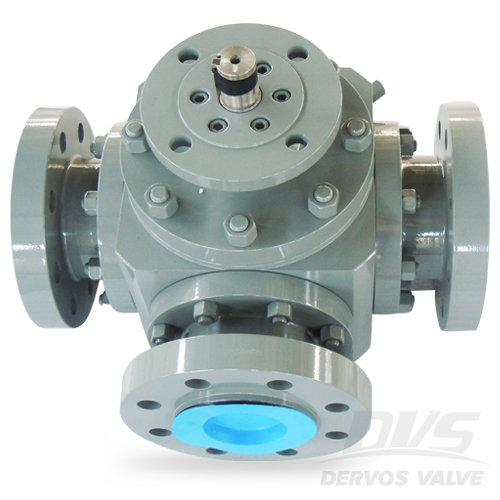

Three Way Ball Valve, ASME B16.34, A351 CF8M, 1000 WOG, NPT

Key Specifications / Features

The Three Way Ball Valve Factory in China specializes in producing high-quality valves that meet ASME B16.34 standards. These valves are crafted from cast stainless steel (ASTM A351 CF8M), ensuring robustness and corrosion resistance. Available in customized sizes, they offer a maximum working pressure of 1000 WOG (Water, Oil, and Gas) and feature a full port design for minimal flow restriction. The valves come with NPT threaded ends for easy integration into existing systems, making them suitable for a wide range of industrial applications.

Detail Information

Product Name: Three Way Ball Valve, FP

Design Standard: ASME B16.34

Body Material: ASTM A351 CF8M

Size: Customized

Pressure: 1000 WOG

End Connection: NPT Threaded

Operation: Lever

Medium: Water, Oil, Gas, etc

Temperature Range: -20°C to 150°C

Multi-port Ball Valves are available in both "T" port and "L" port configurations. The valve assembly consists of a single valve body, a platform bracket, and four side valve covers integrated with a fixed ball core assembly. The ball core, connected to a valve stem, operates by rotating 90 degrees to open or close. These valves are primarily used for pipeline switching and diversion, and can also be designed with an X-shaped ball core to enable medium reversal functionality.

Structural Features

» Product: Three-way Threaded Ball Valve

» Size: 1/2-4 Inch (DN15-DN100)

» Material: SS 201, SS 304, SS 316 (ASTM A351 CF8, CF8M)

» Pressure Rating: 1000 PSI, PN16

» Suitable Media: Water, oil, air, and certain corrosive liquids (WOG)

» Temperature Range: -20°C to 150°C

» Connection: Female/Female threaded

» Sealing Materials: PTFE, RPTFE, PPL, etc.

» Optional: Locking device or stem extension

» Optional: Direct mounting to ISO 5211

» Flow Options: Full port or regular bore

» Design Standards: ANSI B16.34, API 608

» Wall Thickness Standards: ANSI B16.34, EN 12516-3

» Thread Standards: NPT, BSPT, BSP, PT, DIN 2999, etc.

» Testing Standards: API 598, EN 12266

Send your message to this supplier

FAQs

While circular knitting machines are generally safe to use, it is important to follow the manufacturer’s instructions and take necessary precautions. This may include wearing protective gloves and avoiding loose clothing near the machine.