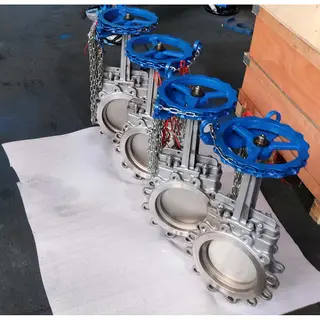

Stainless Steel Knife Gate Valve, A351 CF8M, 12 Inch, CL150

Key Specifications / Features

Detail Information

Product Name: Stainless Steel Slurry Knife Gate Valve

Body Material: ASTM A351 CF8M

Size: 12 Inch, DN300

Pressure: Class 150 LB, PN16

End Connection: Wafer

Operation: Pneumatic Actuator

Temperature Range: -29°C to 120°C

The integral slurry valve features a full-bore design with the entire valve body flow passage lined in wear-resistant polyurethane. This design prevents the flushing medium from contacting the metal body, significantly enhancing wear resistance and extending the valve's service life. With a full-diameter flow path matching the pipeline’s inner diameter, the medium flows smoothly without creating eddy currents, thereby minimizing erosion. When fully open, the valve plate is retracted into the valve chamber, avoiding direct exposure to the medium and further prolonging the disc's lifespan.

Technical Specification

» Nominal Diameter: NPS 2–24 Inch DN50–DN600)

» Design Pressure: PN10, PN16, Class 150 LB

» Working Pressure: 10.3 bar (150 PSI)

» Operating Pressure: 6.2 bar (90 PSI)

» Body Material: GGG40, ASTM A351 CF8, CF8M, Special Alloys, etc.

» Seat Material: EPDM (120°C), NBR (80°C)

» Flange Standard: GB/T 9113.1, JB/T 79.1, HG 20592, ASME B16.5, EN 1092-1

» Face-to-Face: MSS SP-81

» Operation: Manual, Pneumatic, Electric, Hydraulic

» Temperature Range: -29°C to 120°C

Product features

» Self-Cleaning Disc Function: The valve features an internal scraper within the sleeve that automatically cleans the valve plate during each up-and-down movement. This self-cleaning mechanism prevents material buildup, reduces switching torque, and minimizes the risk of blockage.

» Integrated Elastomeric Filler: The sealing filler is integrally molded from wear-resistant, high-rebound rubber. It forms a tight seal with both the stuffing box and the polyurethane-lined valve body, delivering superior sealing performance, extended service life, and simplified replacement.

» Self-Flushing Valve Seat Structure: Designed with a self-flushing seat, the valve prevents slurry sedimentation at the bottom. This ensures complete closure with zero leakage every time, enhancing operational reliability.

» Easy Seat Replacement: The valve seat and upper seal are designed for easy removal. If wear is detected during operation, these components can be replaced on-site. This restoration process returns the valve to its original performance level at only 15–20% of the cost of a full unit replacement.