High Pressure Thermodynamic Steam Trap, ISO 6552, ASTM A105

Key Specifications / Features

Detail Information

Product Name: High Pressure Thermodynamic Steam Trap

Design Standard: ISO 6552

Body Material: ASTM A105

Size: Custom

Pressure: Custom

End Connection: Threaded

Medium: Steam Condensate

The high-pressure thermal steam trap operates based on thermodynamic principles, utilizing the differences in flow rate and volume between steam and condensate. As these fluids pass through the valve orifice, the resulting pressure and velocity changes drive the valve disc to open or close the seat, effectively separating steam from condensate. According to Boergli’s thermodynamic theory, the distinct behaviors of steam and condensate create dynamic and static pressure variations, both kinetic and potential, which generate a pressure differential across the valve disc. This differential causes the disc to actuate, achieving reliable steam trapping and condensate discharge. The CS69Y is widely used in high, medium, and low-pressure steam pipelines and steam tracing systems.

Technical Specification

» Product model: CS69Y Thread

» Nominal diameter: DN15-DN50 (1/2-2 Inch)

» Nominal pressure: PN64-PN160 (Class 600 LB, 900 LB)

» Applicable temperature: -20°C to +550°C

» Applicable medium: Saturated Steam; Superheated Steam

» Connection method: flange connection GB/9113

» Body material: ASTM A216 WCB, A217 WC6, A105, A182 F11, F22

» Disc material: ASTM A276 420

» Seat material: ASTM A276 420

» Filter screen: ASTM A240 304

» Design standard: ISO 6552,GB/T 22654

» Connection length: EN 26554,GB/T 12250

» Experimental verification: EN 26948,GB/T 12251

» Maximum pressure difference: 35 Bar/160 Bar

Product features

» The body material is made of forged chromium molybdenum vanadium steel, which is corrosion-resistant, wear-resistant, high-temperature and high-pressure resistant, and durable.

» Suitable for saturated steam and high-temperature and high-pressure superheated steam conditions, without adjustment throughout the entire working pressure range.

» It has a built-in filter and can replace parts on the pipeline, making maintenance simple.

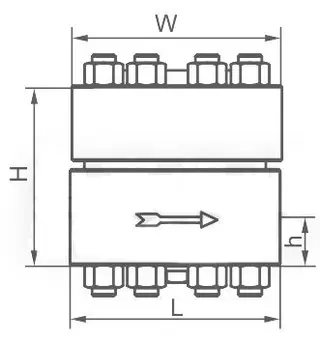

Structural Diagram

Main Dimensions (PN100/CL600)

|

DN |

L |

H |

h |

W |

|

15 |

125 |

112 |

23 |

135 |

|

20 |

125 |

112 |

23 |

135 |

|

25 |

130 |

116 |

27 |

140 |

|

32 |

168 |

153 |

33 |

180 |

|

40 |

168 |

153 |

33 |

180 |

|

50 |

185 |

160 |

40 |

200 |

Main Dimensions (PN160/CL900)

|

DN |

L |

H |

h |

W |

|

15 |

125 |

112 |

23 |

135 |

|

20 |

125 |

112 |

23 |

135 |

|

25 |

145 |

119 |

30 |

155 |

|

32 |

185 |

157 |

37 |

195 |

|

40 |

185 |

157 |

37 |

195 |

|

50 |

205 |

163 |

43 |

220 |