Ductile Iron GGG40 Diaphragm Valve, BS 5156, DN40, PN10, RF

Key Specifications / Features

Detail Information

Product Name: Ductile Iron GGG40 Diaphragm Valves

Type: Straight Through Diaphragm Valve

Design Standard: BS 5156

Body Material: Ductile Iron GGG40

Size: DN40, 1-1/2 Inch

Pressure: PN10, Class 150 LB

End Connection: RF Flanged

Operation: Handwheel

Temperature Range: -29°C to 80°C

In a straight-through diaphragm valve, the diaphragm lifts completely when opened, allowing unobstructed flow in either direction. When closed, the diaphragm forms a tight seal, ensuring reliable shutoff even in pipelines containing gravel or fibrous materials. Compared to weir-type diaphragm valves, this design demands greater diaphragm elasticity, which limits the selection of suitable diaphragm materials to those with high flexibility and durability.

1. Corrosion Resistance

Our diaphragm valves are the ideal choice for applications requiring corrosion resistance. We offer a wide selection of body linings and diaphragm materials to suit various media and operating conditions. This comprehensive range allows for cost-effective solutions without the need for expensive exotic alloys. Our options include elastomer and fluoropolymer linings, specifically engineered to resist aggressive chemicals and corrosive environments.

2. Abrasion Resistance

Our advanced polymer technology ensures exceptional abrasion resistance. Our straight-through diaphragm valves can handle up to 100% solids and, when paired with a soft rubber diaphragm, still maintain a reliable tight shutoff. This performance meets the requirements of MSS SP-88 and BS EN 12266-1 standards.

3. Leak-Tight Performance

Our diaphragm valves provide 100% leak-tight sealing in both pressure and vacuum service conditions, even after thousands of cycles. This performance reduces emissions, minimizes processing losses, and lowers handling costs. All internal operating mechanisms are completely isolated from the process media, ensuring dependable sealing even with frequent cycling or when particulates are present.

4. Easy Maintenance

Designed with a three-part construction, KOSEN diaphragm valves allow for easy maintenance and actuator upgrades without removing the valve body from the pipeline. This modular design simplifies servicing and reduces overall ownership costs.

5. Control Capabilities

Our diaphragm valves offer excellent throttling and flow control performance. The cavity-free, streamlined flow path enhances control accuracy, making these valves suitable for regulating flow across a wide range of applications.

Standards Compliance and Design Features

» Size: 3/4-16 Inch (DN20-DN400)

» Pressure Rating: ANSI Class 125 LB, Class 150 LB, PN6, PN10, PN16

» All Standards: MSS SP-88, BS 5156, ASME B16.34, DIN 3202, ASME B16.1, BS EN 558, ASME B16.5 CL150, EN 1092, EN 12226, ISO 5208, API 598, BS 4504 or equivalents

» Materials: Cast Iron, Ductile Iron, Carbon Steel, Stainless Steel, or Other Specials

» Optional Lining: Natural Rubber, Butyl, EDPM, Hard Rubber and etc.

» Ends Connections: Flanged RF or FF, Screwed

» Optional Locking Device Position indicator

» Optional Direct Mounting to ISO 5211

» Regular Bore

» Handwheel, Electric or Pneumatic operated

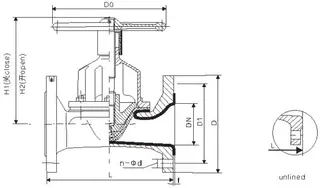

Structural Diagram

Main Material

|

Item No |

Part Name |

Material |

|

1 |

Body |

Cast Iron, carbon steel, Stainless steel |

|

2 |

Bonnet |

Cast Iron, carbon steel, Stainless steel |

|

3 |

Lining |

Rubber lining and fluorine lining |

|

4 |

Diaphragm |

Rubber |

|

5 |

Disc |

Cast Iron, carbon steel |

|

6 |

Stem |

carbon steel, Stainless steel |

|

7 |

Handweel |

Cast Iron |