DBB Floating Ball Valve, EEMUA 182, 1500 LB, RTJ+FNPT, Lever

Key Specifications / Features

Detail Information

Product Name: DBB Floating Ball Valve

Features: Double Block and Bleed, Side Entry, Forged Steel

Design Standard: EEMUA 182

Body Material: Customized

Size: Customized

Pressure: Class 1500 LB, PN250

End Connection: RTJ Flanged + FNPT

Operation: Lever

Double Block and Bleed Valves are designed to ensure double isolation by incorporating two obturators within a single body, with a bleed/vent system positioned between the obturators (body port and ball, gate, or needle valve). Derived from the floating ball valve design, these DBB valves are available in various constructions to meet diverse application needs.

Double block and bleed ball valves (DBB ball valves) effectively isolate a pipe section from both ends, providing a secure and reliable shut-off. This design minimizes the risk of accidental leaks, ensuring safety in critical applications such as the oil and gas industry. In addition to robust safety features, these valves optimize system efficiency by reducing the need for additional valves, saving both space and costs.

Technical Specification

» Size Range: NPS 1/2–2 Inch (DN15–DN50)

» Design Pressure: Class 150–2500 LB (PN10–PN420)

» Temperature Range: -46°C to 350°C

» Materials:

Body: Forged Carbon Steel, Stainless Steel, Duplex, or Other Special Alloys (ASTM A105N, A352 LF2, A182 F11, F22, F304, F304L, F316, F316L)

Trim: 13%Cr, SS 304, SS 304L, SS 316, SS 316L, and other specials

» Medium: Water, Gas, Oil, etc.

» End Connections: Flanged x Flanged, Flanged x FNPT

» Operation: Handle, Worm Gear, Electric, Pneumatic

» Standards

Design and Manufacture: API 6D, BS 5351, ASME B16.34

Face to Face (End to End): Manufacturer's Standard

Flanged Connection: ASME B16.5

Threaded Ends: ASME B1.20.1

Test and Inspection: EEMUA 182, API 598

Fire Safety: API 607, API 6A

Product Features

» DBB Integrated Body with Dual Type Design

» Side Entry Forged Steel Valves

» Optional Top-Entry Design upon Request

» Low Pressure Loss Through the Valve

» Low Actuation Torque

» Available in Full Bore or Reduced Bore

» Materials with Anti-Corrosion Properties as per NACE MR 0175

» Metal Sealed Seat Pocket Area Overlay, Seal Area Overlay, or Complete Cladding on Wetted Surface (Welded Overlays in Inconel 625, Stainless Steel 316, etc., or Electroless Nickel Plating)

Send your message to this supplier

FAQs

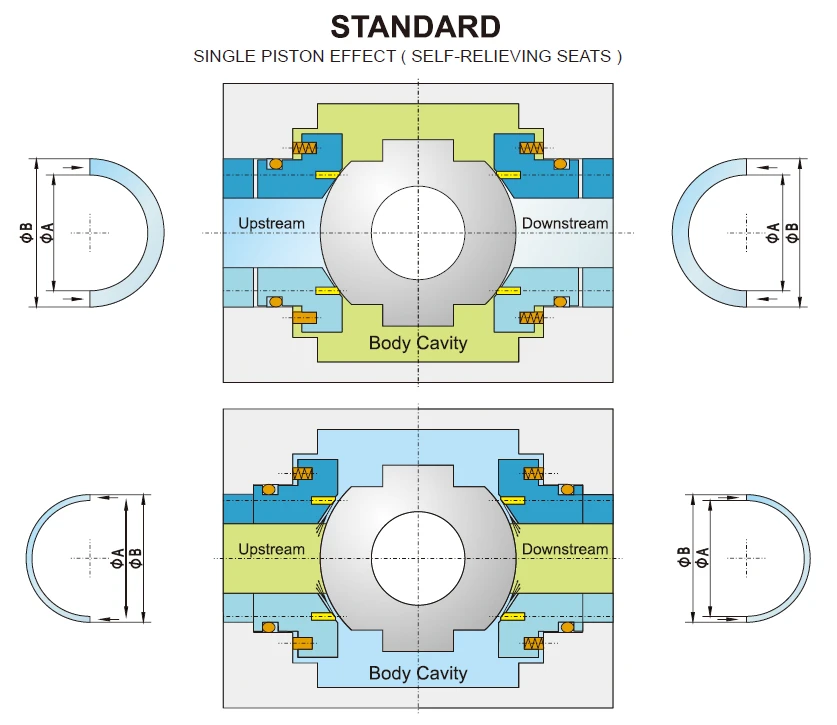

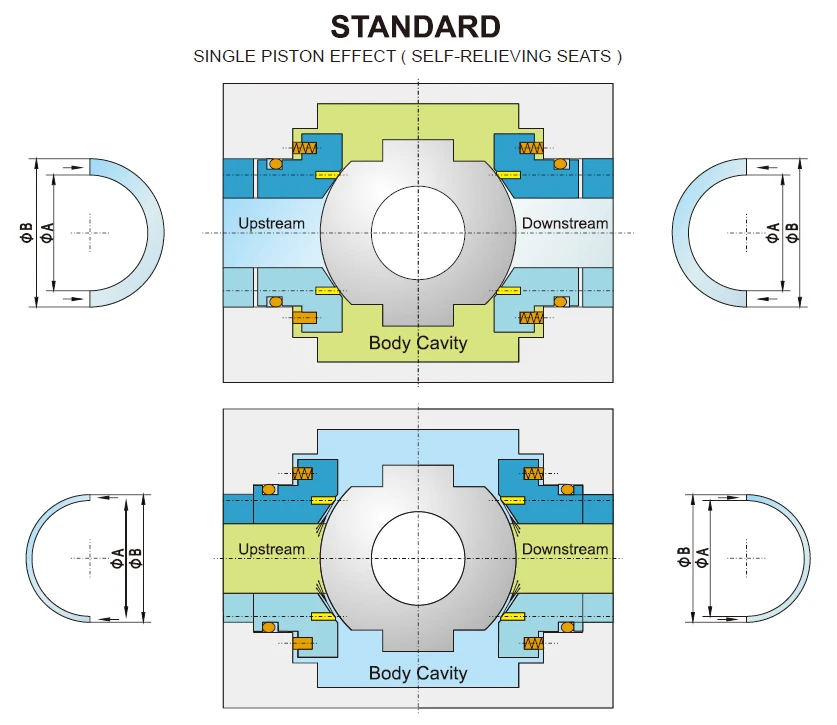

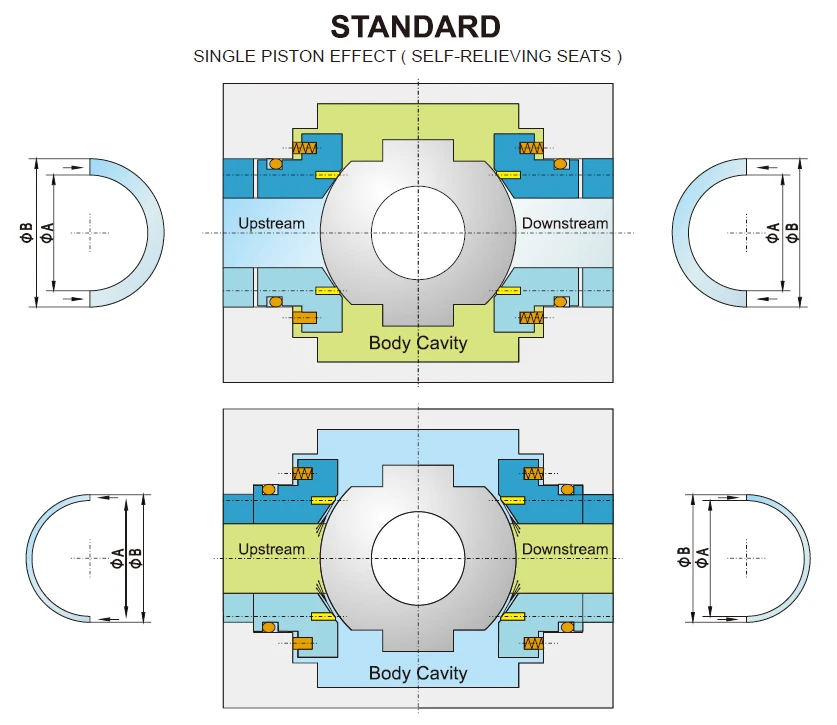

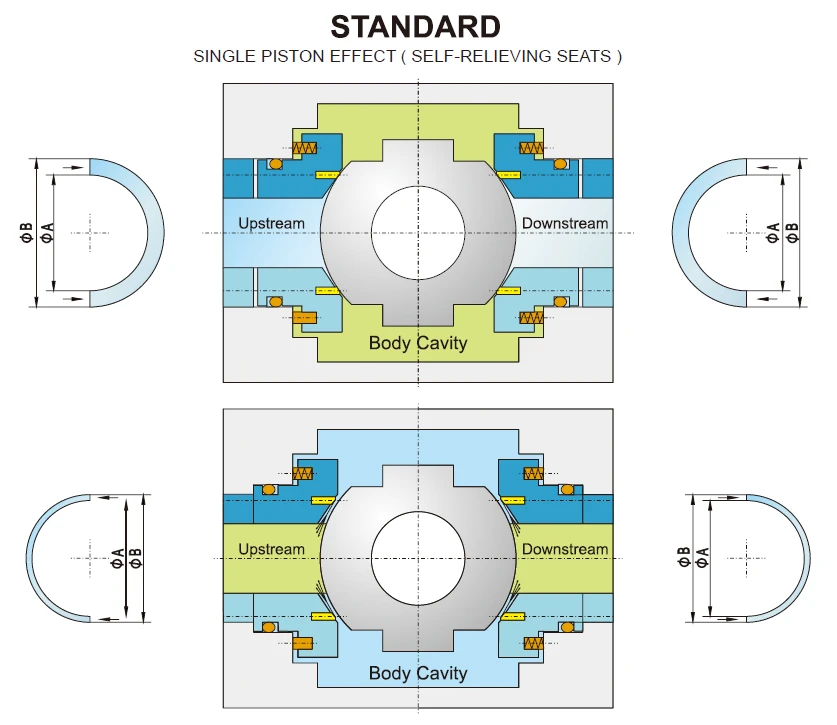

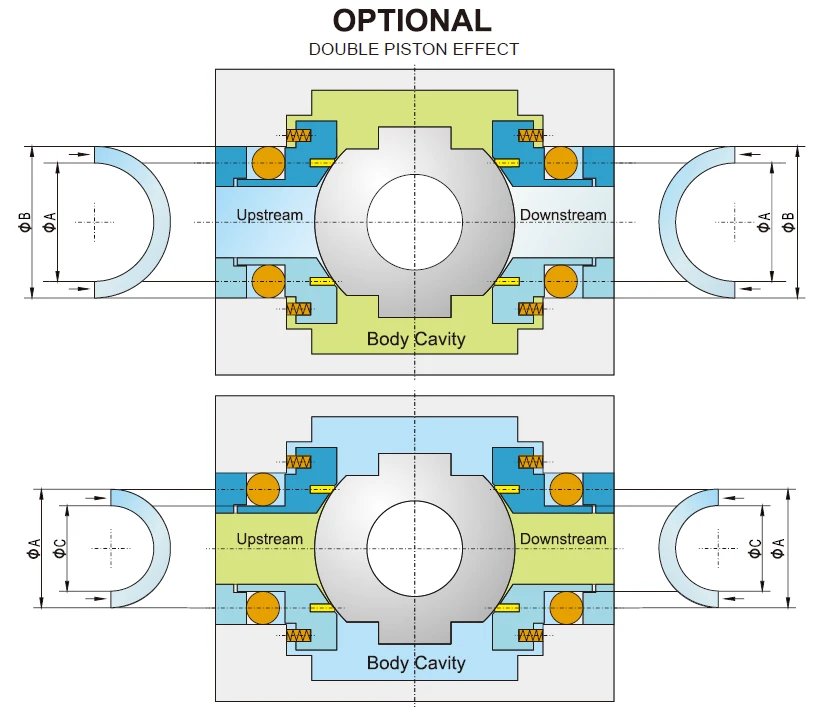

DBB (Double Block and Bleed): Two single piston-effect seats.

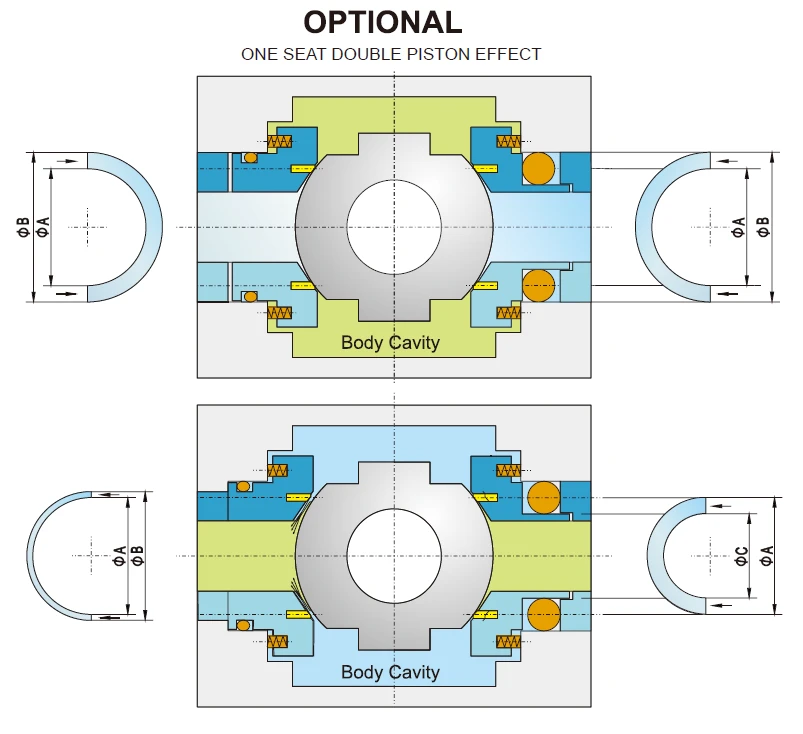

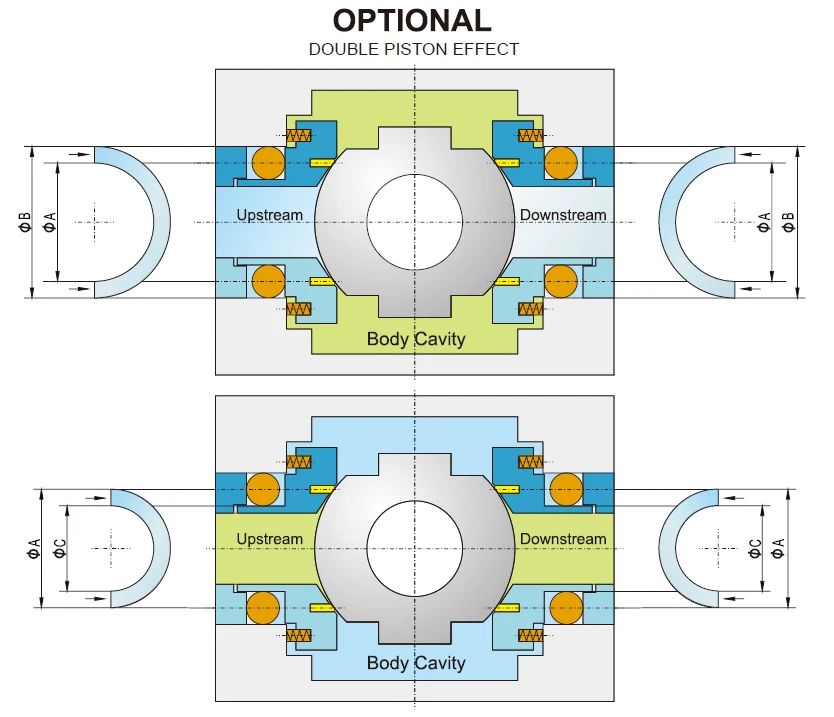

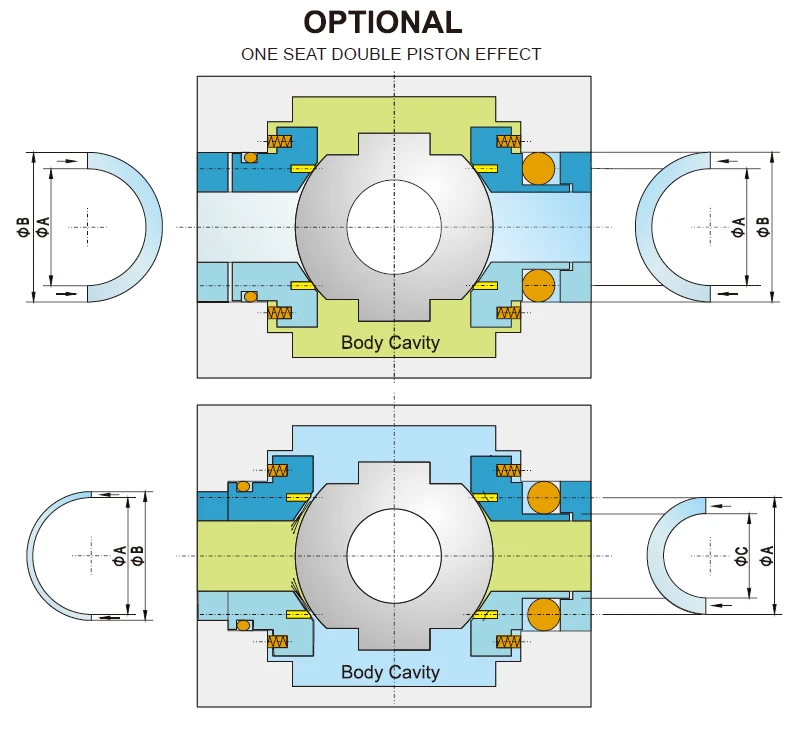

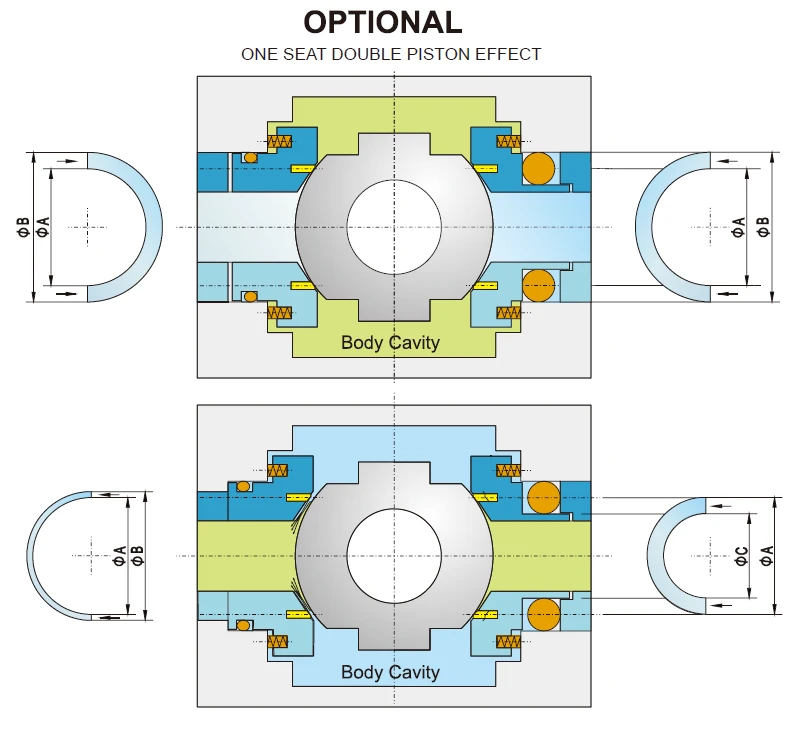

DIB-I (Double Isolation and Bleed Type I): Two double piston-effect seats.

DIB-II (Double Isolation and Bleed Type II): One double piston-effect seat and one single piston-effect seat.

DBB — двойной запор и сброс (два отдельных поршневых седла)

DIB-I (двойные двойные поршневые седла)

DIB-II (одно двойное поршневое седло и одно одинарное поршневое седло)

DBB - Doble Bloqueo y Purga (dos asientos de pistón simple)

DIB-I (dos asientos de pistón doble)

DIB-II (un asiento de pistón doble y un asiento de pistón simple)