Bolted Bonnet Swing Check Valve, API 6D, ASTM A216 WCB, 2 IN

Key Specifications / Features

The Bolted Bonnet Swing Check Valve Plant offers a robust Swing Check Valve designed to meet stringent industry standards. This valve is constructed from high-quality Carbon Steel (ASTM A216 WCB) and adheres to API 6D specifications, ensuring reliability and durability. It features a 2-inch (DN50) size with a Class 300 LB pressure rating, equivalent to PN50, and comes with RF (Raised Face) flanged ends for secure and leak-free connections.

Detail Information

Product Name: Bolted Bonnet Swing Check Valve

Type: Swing Check Valve

Design Standard: API 6D

Body Material: ASTM A216 WCB, Carbon Steel

Size: 2 Inch, DN50

Pressure: Class 300 LB, PN50

End Connection: RF Flanged

Medium: Water, Oil, Gas, etc

Temperature Range: -29°C to 595°C

Universal Cast Steel Check Valves are designed and manufactured in strict accordance with International Standards such as API 6D, BS 1868, ASME B16.34, or equivalent. These valves are engineered to minimize flow resistance and pressure drop, ensuring optimal performance. They are specifically designed for horizontal installation only. The lapped and screwed seat ring ensures a tight seal and long-lasting service. The valve’s disc is precisely designed and machined to achieve efficient automatic shut-off at zero pressure, featuring a compact structure and low-emission service. In its standard configuration, the swing check valve has a bolted cover and a free-swinging clapper, which acts as the closing member and responds to flow conditions. Swing check valves are best suited for horizontal pipeline installations. However, for heavier disc weights, chattering issues may occur, necessitating the use of dampers or counterweights.

Technical Specification

» Type: Swing Check Valve

» Nominal Diameter: NPS 2-24 Inch (DN50-DN600)

» Design Pressure: Class 150-2500 LB (PN10-PN420)

» Material: ASTM A216 WCB, WCC, 217 WC6, WC9, C5, C12A, A352 LCB, LCC, A351 CF8, CF8M, CF3M, CF8C

» End Connections: Flanged (FF, RF, RTJ) to international standards

» Design and Manufacture: BS 1868, API 6D, DIN 3352

» Face to Face (End to End): ANSI B16.10, EN 558 series

» Flanged Connection: ASME B16.5, ASME B16.47, EN 1092 series

» Butt Welded End: ANSI B16.25

» Test and Inspection: API 598, ISO 5208, EN 12266-1

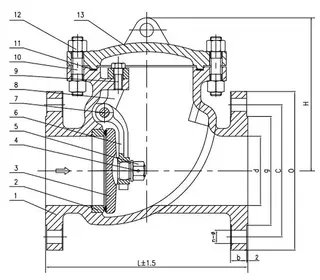

Structural Diagram

Product Features

» Cast steel swing check valve is used to prevent backflow in the line. Flow is in a straight line through the valve, resulting in minimal pressure drop. The disc swings into the open position as the media flows through the line. Back pressure in the line holds the disc in the closed position.

» Cast steel swing check valves may be installed in horizontal or vertical lines, but must be installed in proper relation to the media flow as indicated by the flow direction arrow marked on the body.

» Accessories such as bypasses, locking devices, counterweights, and many others are available to meet customers' requirements.