ASTM B148 C95400 Concentric Butterfly Valve, API 609, 4 Inch

Key Specifications / Features

Detail Information

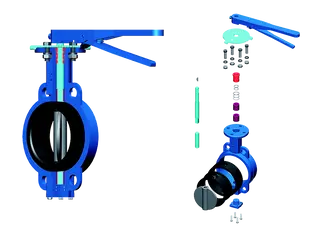

Product Name: Wafer Concentric Butterfly Valve

Design Standard: API 609

Body Material: ASTM B148 C95400

Size: 4 Inch, DN100

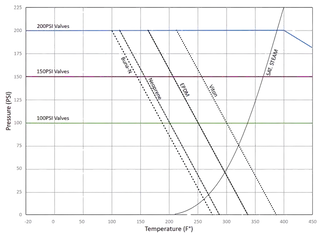

Pressure: Class 150 LB, PN20

End Connection: Wafer

Operation: Lever

The Wafer Concentric Butterfly Valve is designed to maintain a seal against bi-directional pressure differentials, preventing backflow in systems intended for unidirectional flow. It achieves this with a tightly fitting seal, gasket, O-ring, and precision machining, featuring flat valve faces on both the upstream and downstream sides. The valve includes threaded inserts on both sides of the valve body, allowing installation using two sets of bolts without the need for nuts. The valve is installed between two flanges, with a separate set of bolts for each flange. This configuration enables either side of the piping system to be disconnected without disturbing the other side.

Technical Specifications

» Size Range: 2-24 Inch (DN50-DN600)

» Pressure Ratings: Class 150 LB, PN10, PN16

» Materials: GG25, GGG40, ASTM A216 WCB, A351 CF8, CF8M, CF3, CF3M

» Optional Seat Materials: Resilient NBR, EPDM, VITON

» Operation: Handle, Handwheel, Pneumatic, Electric

» End Connections: Wafer, Lug, RF Flange

» Design and Manufacture Standards: GB/T 12228, API 609

» Face-to-Face (End-to-End) Standard: GB/T 12221

» Flanged Connection Standards: ANSI B16.5, GB/T 9113

» Test and Inspection Standards: API 598, GB/T 13927

» Temperature Range: -29°C to 120°C

» Medium: Water, Gas, Oil, etc.

Concentric Lining Butterfly Valve

Concentric Lining butterfly valve adopts lining on all the parts that contact with medium inside of body, the stainless steel which is resistance of corrosion is used as stem and disc to ensure the corrosion resistance of different strong corrosive medium. The valve body and disc materials can be made of cast iron, carbon steel or stainless steel to ensure the bearing strength. Many kinds of soft sealing material such as NBR, EPDM or PTFE etc can be used as lining material to adapt to different corrosive medium or working temperature.

Structural Features

- The indicator plate has multiple opening angles ranging to 90 degrees, which is convenient to locate the gate.

- Top flange as per ISO 5211 to allow for the easy installation of gear box and actuators.

- O-rings provide positive stem sealing performance.

- Note: Alternative packing solutions available.

- Dual stem design reduces valve operating torque.

- Upper and lower bearings minimize operating torque.

- The semi-circular butterfly plate design reduces operating torque and promotes extended service life.The seal ring is supported to achieve disassembly and prevent leakage of the seal ring.

- The seal ring extends to the end of the body and is installed without additional gaskets.

ISO 5211 Top Mounting

Different End Connections Available:

Pressure/Temperature Ratings Chart: