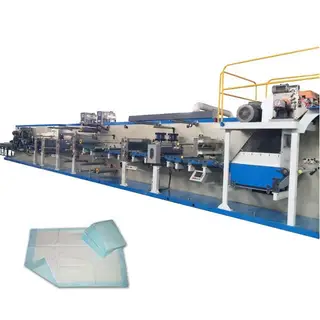

Economical Disposable Underpad Making Machine

Key Specifications / Features

Detail Information

Functions and Features

1. Reasonable structure and refined parts make it reliable when being used and the assembled function makes the transportation and installation much easier.

a) It is controlled under the touch screen. It is easier to operate and adjust.

b) During the process of operation, the quantity of velvet laid for the core can be under non-step adjustment and the combine roller can be used to ensure appropriate thickness of the core. Besides, wastes of fluff pulp can also be recycled and re-feeding.

c) All the products are fully embossed, making them bright and good-looking.

d) Machine can produce products of different sizes. Release paper can be added to the back sheet as optional .

e) Tissue paper, air-laid paper and fluff pulp can be used to produce under pads.

f) SAP can be supplied at a fixed amount in designed locations or in a fixed position.

Option Device

1. The length of products can be realized through frequency adjustment without stopping and changing any spare parts, so as to reduce the wastage rate and increase the work efficiency.

2. Back side release paper or tape can be chosen to use.

Main Technical Parameters

a) Model: DNW-CFD

b) Designed speed: 100 M/Min

c) Real production Speed: 80 M/Min

d) Product size: L: (350-1500)mmxW(300-900)mm customer needs choosing to fix several sizes.

e) Electricity: 380V 50HZ,

f) Cable: (3x50mm2+1x25mm2+1x10mm2)

g) Air compressor: ≥0.6mpa ,1.2m3/min

h) Installation Capacity: 100kw(including glue applicators)

i) Real running capacity: 80KW .Breaker: 250A

j) Machine size(without crusher): (20x4x3)M(LxWxH)

k) Machine operation area: (24x8x4)M(LxWxH)

l) Weight: 20T

m) Container: 2x40HQ

Send your message to this supplier

FAQs

Taking the petroleum refining industry as an example, if a conventional valve has a daily average leakage rate of 500 standard cubic meters (calculated based on the volume of gas under standard conditions), for a large refinery with 100,000 valves, the annual media emission loss can be quantified in the following dimensions.

1. Direct Material Loss

Annual leakage volume = 100,000 valves × 500 Nm³/valve•day × 365 days = 1.825 billion standard cubic meters of gas. If the unit price of natural gas is 3 yuan/Nm³, the annual direct economic loss reaches 5.475 billion yuan (without considering the cost of media recovery).

2. Increased Operation and Maintenance Costs

High leakage rates lead to a 3-5 times increase in on-site inspection frequency, with an additional annual maintenance cost of 2,000-3,000 yuan per valve, resulting in an extra 200 million - 300 million yuan in annual O&M costs for the entire plant; emergency shutdowns and repairs caused by sudden leaks can result in average losses of millions of yuan per incident.

3. Compliance Risk Costs

Leakages exceeding environmental emission standards (such as the volatile organic compound leakage limits specified in China's "Pollutant Emission Standards for the Petroleum Chemical Industry") may face:

Single administrative penalty: 100,000 - 1 million yuan

Production suspension and rectification: Daily value loss can reach tens of millions of yuan

Brand reputation loss: Leading to downstream customer loss or restricted financing

4. Release of Hidden Value

Using low emission valves (leakage rate ≤0.1 Nm³/valve•day) can achieve:

Annual emission reduction of over 1.8 billion cubic meters, meeting the carbon trading market quota requirements and creating additional revenue

More than 40% improvement in operation and maintenance efficiency, with a 5%-8% increase in overall equipment utilization rate

Avoidance of the risk of downgraded environmental credit rating, ensuring project approval and expansion qualifications

Conclusion: Low Emission Valves, through a three-dimensional value system of "material conservation control, operation and maintenance efficiency optimization, compliance risk isolation", can not only directly reduce losses of hundreds of millions of yuan but also build a sustainable development capability that meets ESG (environmental, social, and corporate governance) requirements. Especially under the "dual carbon" goals, they have become a core cost control tool for industries with high leakage risks.