Factors to Be Considered in Butterfly Valves' Design (Part Four)

7. Service lives

Normal failure of butterfly valves is leakages, and butterfly valves' leakages include external leakages and internal leakages. External leakages are mainly caused by erosion or corrosion, and internal leakages are caused by damage to sealed auxiliaries. Service lives usually refer to sealed auxiliaries' using time or times of actions, which depend on types, temperatures, pressure, opening and closing frequency and opening and closing speeds of butterfly valves. Thus, we can choose materials which can meet working conditions, materials with scratch resistance, fatigue resistance and electrochemical corrosion resistance, and have necessary heat treatments for these materials. In addition, the service life of the sealing auxiliary is closely related to the rationality of the structural design and the manufacturing accuracy.

8. Selection of main parts' materials

The main part of the butterfly valve includes the valve body, the butterfly plate, the valve stem, the valve seat and the sealing ring. We choose materials based on working conditions, and we should especially pay attention to corrosion resistance and applicable temperatures of materials. The following table shows the applicable temperature and the applicable medium of the commonly used material.

Normal failure of butterfly valves is leakages, and butterfly valves' leakages include external leakages and internal leakages. External leakages are mainly caused by erosion or corrosion, and internal leakages are caused by damage to sealed auxiliaries. Service lives usually refer to sealed auxiliaries' using time or times of actions, which depend on types, temperatures, pressure, opening and closing frequency and opening and closing speeds of butterfly valves. Thus, we can choose materials which can meet working conditions, materials with scratch resistance, fatigue resistance and electrochemical corrosion resistance, and have necessary heat treatments for these materials. In addition, the service life of the sealing auxiliary is closely related to the rationality of the structural design and the manufacturing accuracy.

8. Selection of main parts' materials

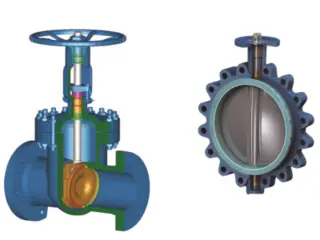

The main part of the butterfly valve includes the valve body, the butterfly plate, the valve stem, the valve seat and the sealing ring. We choose materials based on working conditions, and we should especially pay attention to corrosion resistance and applicable temperatures of materials. The following table shows the applicable temperature and the applicable medium of the commonly used material.

Applicable temperatures and applicable media of commonly used materials

| Parts' name | Grades | Applicable temperatures | Applicable media |

| HT200 | From -10 to 200 ℃ | Water, steam, air and gas | |

| Valve bodies | ZG230-450 | From -30 to 450℃ | Water, steam, air and gas |

| ZG12Cr18Ni9 | From-196 to 600℃ | Corrosive media | |

| HT200 | From-10 to 200℃ | Water, steam, air and gas | |

| Butterfly plates | ZG230-450 | From-30 to 450℃ | Water, steam, air and gas |

| ZG12Cr18Ni9 | From-196 to 600℃ | Corrosive media | |

| Valve stems | 2Cr13 | Lower than or equal to 700℃ | Corrosive media |

| 40Cr | Lower than or equal to 450℃ | Water, steam, air and gas | |

| Valve seats | 1Cr18Ni9 | From -196 to 600℃ | Water, gas and corrosive media |

| SFB-1 | 150℃Lower than or equal to 150℃ | Corrosive media | |

| Sealing rings | MQ | From-60 to 200℃ | Water, steam and air |

| FPM | From -20 to 200℃ | Corrosive media |

The conclusion

With the improvement of the global energy conservation and the environmental awareness, the process system of the large-scale project constantly changes to the system with high parameters, which puts the higher and more demanding requirement on the technological parameter of the valve. In order to be adapted to functional requirements of working conditions such as high pressure, high temperatures, low temperatures and multiphase flows, structures of butterfly valves are also constantly upgraded and special butterfly valves with high performance appear one after another. However, butterfly valves remain essentially the same despite all apparent changes. Only by knowing process systems' functional requirements on butterfly valves and all parameters of working conditions, can we design butterfly valve products which can meet functional requirements and have reliable performance so as to improve productivity.

Send your message to this supplier

Related Articles from the Supplier

Related Articles from China Manufacturers

Cautions for filling grease to valves

- Dec 17, 2018

How to maintain the sealing performance of valves?

- Feb 25, 2019

Related Products Mentioned in the Article

Zhejiang Xinhai Valve Manufacturing Co., Ltd.

- Address: Xinhai Industry Zone, Sanqiao, Oubei, Wenzhou, Zhejiang, P. R. China.

- Phone: +86 577 6699 3222

- Business Type: Industry & Trading, Manufacturer,

Supplier Website

Source: https://www.xinhaivalve.com/factors-to-be-considered-in-butterfly-valves-design-part-four.html