Difference between High Platform and Ordinary Ball Valves

The high platform ball valve adopts the manufacturing standard ISO 5211. A square or round flange and the ball valve are cast into a whole, and the end face of the platform is higher than the outer edges of the flanges at both ends, which not only facilitates the installation of pneumatic actuators, electric actuators and others, but also greatly improves the stability between the valve and the actuator, and makes the valve more beautiful and delicate.

The high platform ball valve is evolved from the conventional ball valve with the bracket. The difference between the high platform ball valve and the common ball valve is that the former can be directly connected with the driving actuator without installing the connecting bracket, while the bracket should be fixed on the latter before installing actuators. In addition, the high platform ball valve is directly installed on the platform, greatly improving the stability between the actuator and the ball valve.

The advantage of the high platform ball valve is that pneumatic or electric actuators can be directly installed on its own platform, while ordinary ball valves need the additional valve to connect with the actuators, which may cause the ball valves to be affected in use due to the loose bracket or the large coupling gap, but the high platform ball valve will not have this problem, and its performance is extremely stable during operation.

The internal structure and the principle of opening and closing of the high platform ball valve is the same as those of ordinary ball valves. In the selection of high platform ball valves and ordinary ball valves, when the medium temperature is relatively high, it is necessary to adopt the connecting bracket to protect the normal use of the actuator and prevent it from being unusable because of the heat transfer of the medium.

The high platform ball valve is evolved from the conventional ball valve with the bracket. The difference between the high platform ball valve and the common ball valve is that the former can be directly connected with the driving actuator without installing the connecting bracket, while the bracket should be fixed on the latter before installing actuators. In addition, the high platform ball valve is directly installed on the platform, greatly improving the stability between the actuator and the ball valve.

The advantage of the high platform ball valve is that pneumatic or electric actuators can be directly installed on its own platform, while ordinary ball valves need the additional valve to connect with the actuators, which may cause the ball valves to be affected in use due to the loose bracket or the large coupling gap, but the high platform ball valve will not have this problem, and its performance is extremely stable during operation.

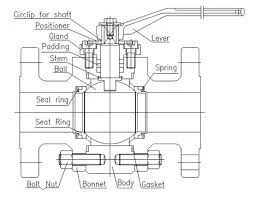

The internal structure and the principle of opening and closing of the high platform ball valve is the same as those of ordinary ball valves. In the selection of high platform ball valves and ordinary ball valves, when the medium temperature is relatively high, it is necessary to adopt the connecting bracket to protect the normal use of the actuator and prevent it from being unusable because of the heat transfer of the medium.

Send your message to this supplier

Related Articles from the Supplier

Difference Between Ball Valve and Butterfly Valve

- Dec 15, 2017

Difference Between Gate Valve and Globe Valve

- Mar 19, 2018

Different Connection Ends for Valves

- May 06, 2021