The Correct Selection of Seamless Steel Pipes-Part 2

(2) Low alloy steel seamless pipes

In petrochemical production units, the commonly used standards of seamless steel pipes of chromium molybdenum steel and chromium molybdenum vanadium steel are as follows:

GB9948 Seamless Steel Pipe for Petroleum Cracking

GB6479 High Pressure Seamless Steel Pipes for Fertilizer Equipment

GB/T5310 Seamless Steel Pipes for High Pressure Boilers

Material grades of GB9948 containing chromium molybdenum steel: 12CrMo, 15CrMo, 1Cr2Mo, 1Cr5Mo, etc.

Material grades of GB6479 containing chromium molybdenum steel: 12CrMo, 15CrMo, 1Cr5Mo, etc.

Material grades of GB/T5310 including chromium-molybdenum steel and chromium-molybdenum vanadium steel: 15Mog, 20Mog, 12CrMog, 15CrMog, 12Cr2Mog, 12Cr 1MoVg, etc.

Among them, the more commonly used standard is GB9948, and please kindly see the above selection conditions.

(3) Stainless steel seamless steel pipes

Common standards of stainless steel seamless steel pipes are GB/T14976, GB13296, GB9948, GB6479 and GB5310. Among them, only two or three grades of stainless steel materials are listed in the last three standards. In addition, they are not commonly used material grades. Therefore, when the engineering select the standards of stainless steel seamless steel pipes, GB/T14976 and GB13296 standard will be chosen.

GB/T14976 Seamless Stainless Steel Pipes for Fluid Conveying

Material grades: there are a total of 19 kinds, like 304, 304L, etc, which are suitable for general fluid transport.

GB13296 Stainless Steel Seamless Steel Pipes for Boilers and Heat Exchangers

Material grades: there are a total of 25 kinds, such as 304 and 304L.

Ultra-low carbon stainless steels (304L, 316L) have excellent corrosion resistance. Under certain conditions, they can replace stable stainless steels (321, 347) for corrosion resistance of medium. The high temperature mechanical properties of ultra-low carbon stainless steel are low. They are generally only used below 525℃. Stable austenitic stainless steel has good corrosion resistance and high temperature mechanical properties. However, TI in 321 is easy to be oxidized and lost in the welding process. Thus, its corrosion resistance reduces. The price is high, and this kind of material is generally used on important occasions. 304 and 316 have general corrosion resistance, cheap, so they are widely used.

In petrochemical production units, the commonly used standards of seamless steel pipes of chromium molybdenum steel and chromium molybdenum vanadium steel are as follows:

GB9948 Seamless Steel Pipe for Petroleum Cracking

GB6479 High Pressure Seamless Steel Pipes for Fertilizer Equipment

GB/T5310 Seamless Steel Pipes for High Pressure Boilers

Material grades of GB9948 containing chromium molybdenum steel: 12CrMo, 15CrMo, 1Cr2Mo, 1Cr5Mo, etc.

Material grades of GB6479 containing chromium molybdenum steel: 12CrMo, 15CrMo, 1Cr5Mo, etc.

Material grades of GB/T5310 including chromium-molybdenum steel and chromium-molybdenum vanadium steel: 15Mog, 20Mog, 12CrMog, 15CrMog, 12Cr2Mog, 12Cr 1MoVg, etc.

Among them, the more commonly used standard is GB9948, and please kindly see the above selection conditions.

(3) Stainless steel seamless steel pipes

Common standards of stainless steel seamless steel pipes are GB/T14976, GB13296, GB9948, GB6479 and GB5310. Among them, only two or three grades of stainless steel materials are listed in the last three standards. In addition, they are not commonly used material grades. Therefore, when the engineering select the standards of stainless steel seamless steel pipes, GB/T14976 and GB13296 standard will be chosen.

GB/T14976 Seamless Stainless Steel Pipes for Fluid Conveying

Material grades: there are a total of 19 kinds, like 304, 304L, etc, which are suitable for general fluid transport.

GB13296 Stainless Steel Seamless Steel Pipes for Boilers and Heat Exchangers

Material grades: there are a total of 25 kinds, such as 304 and 304L.

Ultra-low carbon stainless steels (304L, 316L) have excellent corrosion resistance. Under certain conditions, they can replace stable stainless steels (321, 347) for corrosion resistance of medium. The high temperature mechanical properties of ultra-low carbon stainless steel are low. They are generally only used below 525℃. Stable austenitic stainless steel has good corrosion resistance and high temperature mechanical properties. However, TI in 321 is easy to be oxidized and lost in the welding process. Thus, its corrosion resistance reduces. The price is high, and this kind of material is generally used on important occasions. 304 and 316 have general corrosion resistance, cheap, so they are widely used.

Send your message to this supplier

Related Articles from the Supplier

The Correct Selection of Seamless Steel Pipes-Part 2

- Sep 26, 2021

The Correct Selection of Seamless Steel Pipes-Part 1

- Sep 26, 2021

The Forming Method of Square Steel Tube

- Jul 20, 2020

Related Articles from China Manufacturers

The correct selection of seamless carbon steel pipes

- Jul 08, 2020

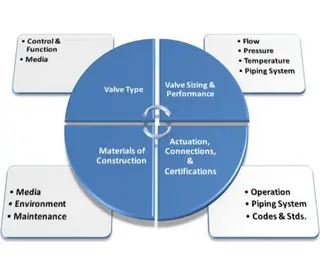

The Correct Direction for Installing Ball Valves

- Dec 09, 2021

The principle of anti-corrosion steel pipe

- Dec 19, 2023

Related Products Mentioned in the Article

- www.chinatopper.com

- Address: Xiamen

- Phone: 86-592-5819200

- Business Type: Trading, Industry & Trading, Manufacturer,

Supplier Website

Source: https://www.pipessteel.com/news/the-correct-selection-of-seamless-steel-pipes-part-2.html