Three Way Ball Valve: Function, Types, Applications, and Maintenance

Introduction

Valves are the unsung heroes of industrial piping systems. They regulate, direct, and control the movement of fluids and gases that power everything from water treatment facilities and HVAC systems to oil refineries and pharmaceutical plants. Within this broad category, the three way ball valve holds a special place because of its versatility and efficiency.

Unlike conventional two-way valves, which allow media to move in only one direction (inlet to outlet), three way ball valves open up more possibilities. By incorporating a ball with three ports inside the valve body, they allow operators to divert flow, mix multiple streams, or isolate pipelines — all with a simple quarter-turn.

As industries demand more flexible, compact, and cost-effective solutions, the three way ball valve continues to grow in importance. This article takes a deep dive into the technology: what it is, how it works, its types, advantages and limitations, common problems, best practices for maintenance, and its evolving role in modern industrial systems.

What Is a Three Way Ball Valve?

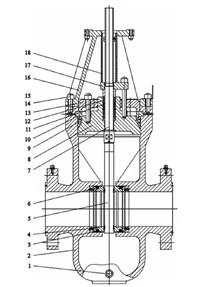

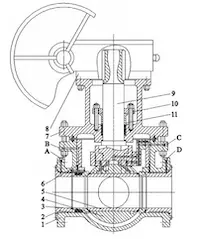

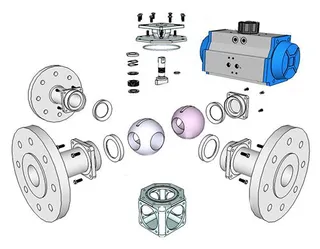

At its core, a three way ball valve is a rotary-motion valve. Inside the valve body is a polished, perforated ball with a through-hole that aligns with the ports in different configurations. By rotating the actuator or handle 90 degrees, the ball’s passage changes the path of flow.

Key features:

Three connection ports: labeled A, B, and C, each can act as inlet or outlet depending on orientation.

Quarter-turn operation: quick and easy to operate.

High sealing performance: when closed, ball valves provide tight shutoff.

Low pressure drop: thanks to the ball’s smooth bore design.

Unlike throttling valves (e.g., globe valves), ball valves — including three way variants — are primarily intended for on/off or directional control rather than fine flow regulation. Still, their simplicity, durability, and adaptability make them a favorite across industries.

Types of Three Way Ball Valves

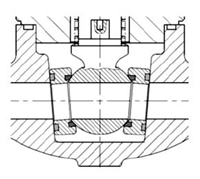

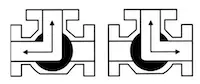

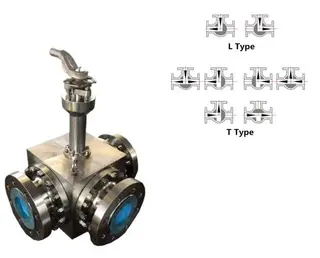

Three way ball valves come in two main configurations: L-Port and T-Port. Both share the same working principle but differ in internal ball passage shape, which dictates their function.

L-Port Configuration

Ball passage design: shaped like an “L.”

Function: diverting flow.

Typical operations:

Connect one inlet to one of two possible outlets.

Switch flow direction between two pipelines.

Example: In a water treatment plant, an L-port valve can switch raw water flow between two different filtration units.

T-Port Configuration

Ball passage design: shaped like a “T.”

Function: mixing and diverting.

Typical operations:

Combine flow from two inlets into one outlet.

Split one inlet into two simultaneous outlets.

Example: In beverage processing, a T-port valve can blend two ingredients into one outlet pipeline or send one stream into two tanks at once.

Flow Patterns and Configurations

Diverting: send one stream to multiple outlets.

Mixing: combine two streams into one.

Isolating: shut off flow to one or more lines.

The choice between L-port and T-port depends entirely on the system’s flow requirements.

Operation: Manual vs. Automated

Three way ball valves can be operated in different ways depending on application:

Manual Operation

Controlled with a handle or lever.

Best for low-frequency operation, small systems, or where human supervision is available.

Automated Operation

Equipped with actuators (electric, pneumatic, or hydraulic).

Suitable for remote control, frequent switching, or integration with SCADA/PLC systems.

Pneumatic actuators are fast and reliable in hazardous areas, while electric actuators are common in automated plants.

Advantages of Three Way Ball Valves

Design Efficiency

Eliminates the need for multiple two-way valves and complex piping.

Reduces installation footprint and costs.

Operational Flexibility

One valve can perform multiple functions: diverting, mixing, or shutting off.

Switching between flow paths is fast and simple.

Durability

With proper material selection, they withstand high pressures, high temperatures, and corrosive media.

Fewer moving parts compared to plug or globe valves.

Safety and Reliability

Tight shutoff prevents leakage.

Options for lockable handles reduce accidental operation.

Ease of Maintenance

Many three way ball valves are designed for easy disassembly.

Replacement of seats and seals can be done without removing the valve from the pipeline.

Disadvantages and Limitations of Three Way Ball Valve

Limited Throttling Capability

Not suitable for precise flow control; mainly used for routing.

Potential Leakage Between Ports

If seals wear out, unintended mixing or bypass can occur.

Application-Specific Selection

Wrong choice of L-port or T-port can cause misrouting.

Size Limitations

While available in many sizes, very large diameters are less common compared to gate or butterfly valves.

Material Constraints

In abrasive or extremely corrosive environments, wrong material selection leads to premature failure.

Materials of Construction

Selecting the right material ensures the valve matches the fluid’s chemistry, pressure, and temperature.

Stainless Steel (CF8M / 316): Excellent corrosion resistance; used in chemical and food industries.

Carbon Steel: Economical for non-corrosive services such as oil pipelines.

Brass/Bronze: Common in HVAC and potable water systems.

PVC / Plastic: Lightweight, corrosion-resistant, ideal for low-pressure chemical applications.

Exotic Alloys (Hastelloy, Monel, Titanium): For highly aggressive chemicals, seawater, or high-temperature gases.

Seat and seal materials are equally important. Options include PTFE (Teflon), RPTFE (reinforced PTFE), PEEK, or metal seats depending on service conditions.

Industrial Applications of Three Way Ball Valve

Three way ball valves are used wherever flow redirection or mixing is needed. Some major sectors include:

1. HVAC Systems

Switching chilled or hot water between loops.

Controlling heat exchangers and cooling towers.

2. Food & Beverage Processing

Sanitary-grade valves used for milk, juice, beer, and syrups.

Easy-to-clean designs meet FDA and 3A sanitary standards.

3. Water & Wastewater Treatment

Switching between different treatment tanks.

Controlling disinfection processes with chlorine or ozone dosing.

4. Oil & Gas Industry

Diverting crude oil streams.

Blending natural gas with additives.

Handling high-pressure service with metal-seated valves.

5. Chemical and Petrochemical Plants

Mixing or diverting aggressive chemicals.

Used in polymer, resin, and specialty chemical production.

6. Pharmaceuticals

Handling sterile solutions and ingredients.

Designed with clean-in-place (CIP) features.

7. Marine Industry

Bronze and aluminum bronze variants are used for seawater.

Control ballast water and cooling water systems.

Troubleshooting Common Issues

Even robust valves encounter problems. Below are common issues and solutions:

Leakage

Stem Leakage: Caused by worn packing. Tighten gland or replace packing.

Body Joint Leakage: Often due to loose bolts or damaged gaskets. Retighten or replace.

Ball Leakage: Seat wear, debris, or ball erosion. Inspect, clean, or replace components.

Hard to Operate

Cause: Build-up of scale, corrosion, or actuator issues.

Solution: Clean, lubricate, or realign actuator.

Blockage

Cause: Solids or debris trapped inside.

Solution: Flush system, inspect filters, and clean valve.

Incorrect Flow Routing

Cause: Wrong orientation of ball (L-port vs T-port).

Solution: Verify actuator position and correct installation.

Installation and Maintenance Best Practices

Proper installation and maintenance are essential to ensure the long-term reliability and efficiency of three way ball valves. Careful attention during setup can prevent costly downtime, while routine maintenance keeps the valve functioning at its best.

Correct positioning is the first step. Before installation, always align the valve ports according to the system’s flow diagram to avoid misrouting. Once positioned, perform torque-controlled bolting, tightening body bolts evenly with a torque wrench to prevent leaks and maintain structural integrity.

For smooth operation, apply the recommended lubricants to moving parts, which minimizes friction and reduces wear. It is also advisable to perform periodic cycling, turning the valve occasionally even during idle periods to prevent sticking or seizing.

Regular seat and seal inspections are critical. Over time, these components can wear due to pressure, temperature, or abrasive media, so timely replacement helps maintain tight shutoff. Always use OEM parts for gaskets, seals, and other replacements, as they are specifically designed for compatibility and performance.

Finally, cleanliness is vital, especially in industries like food, beverage, and pharmaceuticals. Employ CIP (clean-in-place) or SIP (steam-in-place) procedures to maintain hygiene and prevent contamination.

By following these practices, operators can significantly extend valve service life and ensure consistent performance.

Standards and Certifications

Three way ball valves are designed to meet international standards to ensure performance and safety:

API 6D – Pipeline valves.

ISO 17292 – Metal ball valves for industrial applications.

ASME B16.34 – Pressure-temperature ratings, dimensions, and materials.

FDA & 3A Sanitary Standards – For food and pharma valves.

ATEX Certification – For use in explosive atmospheres.

Future Trends in Three Way Ball Valves

IoT and Smart Monitoring

Sensors integrated into valves for real-time monitoring of pressure, temperature, and leak detection.

Advanced Materials

Development of corrosion-proof composites and ceramic linings.

Energy Efficiency

Lower torque requirements reduce actuator power consumption.

Sustainability

Eco-friendly materials and longer service lifespans to minimize environmental impact.

Conclusion

The three way ball valve is far more than just a simple piping accessory. Its ability to divert, mix, and shut off flow within a single compact body makes it one of the most versatile valves in modern industry. With proper material selection, adherence to standards, and regular maintenance, three way ball valves can deliver decades of reliable service.

From HVAC and water treatment to food production, pharmaceuticals, and oil & gas, these valves are everywhere — silently ensuring that fluids move where they should, when they should. As industries evolve, three way ball valves will continue to adapt, incorporating smart technologies and advanced materials to meet tomorrow’s challenges.

Send your message to this supplier

Related Articles from the Supplier

Everything You Should Know About Three-Way Valves

- Aug 21, 2024

Related Articles from China Manufacturers

Related Products Mentioned in the Article

topper

- www.chinatopper.com

- Address: Xiamen

- Phone: 86-592-5819200

- Business Type: Trading, Industry & Trading, Manufacturer,

Supplier Website

Source: https://www.mfrsvalve.com/news/three-way-ball-valve-function-types-applications-and-maintenance.html