What are Metal C-Ring and O-Ring Gaskets?

Magpie Sealing Technology Insights

Flanges and Gaskets — Sealing Gasket Types (Part 15): What are Metal C-Ring and O-Ring Gaskets?

In this edition, we provide a concise overview of metal C-ring and O-ring gaskets, two high-performance sealing solutions widely used in demanding industries such as petrochemicals and nuclear power.

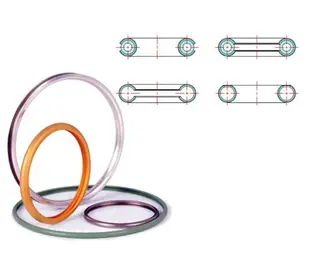

Metal C-Ring and O-Ring Gaskets

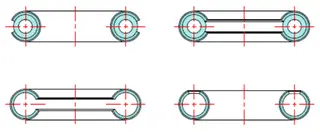

Metal C-ring and O-ring gaskets derive their names from their cross-sectional shapes, C-shaped and O-shaped, respectively. These gaskets offer innovative engineering sealing solutions, characterized by their elastic and pressure-activated sealing capabilities. They are designed to withstand high-pressure and complex service environments.

Structurally, these gaskets may incorporate an internal helical spring and are often coated or plated with a soft sealing material to enhance adaptability and performance. When subjected to bolt preload or radial compression, the gasket deforms axially or radially to generate a preload sealing stress, ensuring reliable sealing under various operating conditions.

One of the key advantages of these gaskets lies in their self-energizing elastic sealing behavior. As the internal media pressure increases, the gasket expands radially or axially, enhancing the sealing force proportionally. This makes them particularly suitable for environments with pressure fluctuations, such as in petrochemical plants or nuclear power systems.

Key Considerations for Use

To maximize the performance of metal C-ring and O-ring gaskets, attention should be paid to the following aspects:

Material and Structure Selection: Choose the appropriate gasket material and structure according to specific working conditions such as temperature, pressure, and media.

Proper Preload During Installation: Ensure the correct tightening force to achieve the necessary sealing stress without causing over-compression or damage.

Regular Inspection and Maintenance: Periodically check gasket conditions and replace any components that show signs of wear or aging.

With advances in materials science and manufacturing technology, the performance of metal C-ring and O-ring gaskets continues to improve. The use of new alloy materials enhances their resistance to extreme temperatures and pressures, while precision machining ensures dimensional accuracy and surface quality, enabling reliable operation in increasingly harsh environments.

Conclusion

Thanks to their elastic, self-tightening sealing mechanism, metal C-ring and O-ring gaskets have become a preferred choice in high-pressure and demanding industrial settings. With proper material selection, standard-compliant installation, and routine maintenance, these gaskets can deliver long-term sealing performance and safety.

For low-leakage sealing challenges, Magpie Sealing provides innovative solutions. If you have questions about sealing technologies, feel free to follow us at Magpie Sealing. We welcome your inquiries, comments, and feedback.

Thank you for reading, and stay tuned for the next installment on sealing gasket forms!

Send your message to this supplier

Related Articles from the Supplier

What are Metal C-Ring and O-Ring Gaskets?

- Jun 19, 2025

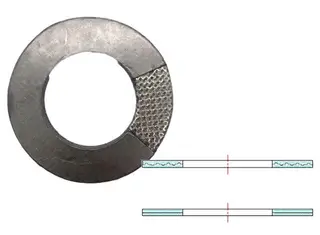

What are Reinforced Flexible Graphite Gaskets?

- Jun 13, 2025

What is High-Temperature Ball Valve?

- Dec 23, 2025

Related Articles from China Manufacturers

Related Products Mentioned in the Article

Supplier Website

Source: https://www.magpievalves.com/what-are-metal-c-ring-and-o-ring-gaskets.html