What Makes a Good Low-Emission Graphite Packing: Our View and Process

Currently, across the global valve industry, low-emission packing solutions generally fall into three main structural types: composite designs (with graphite sandwiched between upper and lower braided rings), fully braided structures, and specially profiled shapes such as V-type or X-type. Many manufacturers also apply various surface impregnation treatments to the packing to enhance sealing performance and reduce emissions.

However, this approach is largely based on the perspective of packing manufacturers and does not necessarily reflect the actual requirements of valve applications in real operating environments.

In real-world scenarios, such as in Northern Europe, pipeline media may operate at 300°C during the day, then drop to -40°C overnight after shutdown. Under such extreme thermal fluctuations, packing materials are subjected to intense tensile stress. This presents the most authentic test of their sealing principles and manufacturing integrity.

We have observed that while some packing manufacturers' packing products can pass ISO 15848-1 type tests from ambient temperature to 400°C and back, they often fail during low-temperature phases, such as from ambient down to -50°C. This is because, in pursuit of lower leakage rates, excessive impregnating emulsions are often used to improve sealing of the packing. However, these additives can introduce undesirable side effects, such as thermal shrinkage at low temperatures and softening at high temperatures. Such treatments pose significant emission risks under operating conditions like those in Northern Europe, where the media fluctuates between +300°C and -40°C.

Moreover, many ISO 15848-1 type tests are performed in separate stages: high-temperature cycles and low-temperature cycles are conducted independently. This segmented testing approach does not fully reflect actual application environments and may leave blind spots in verifying true low-emission performance.

Through long-term research and field validation, we have refined our understanding of performance standards and manufacturing requirements for low-emission graphite packing to better reflect real application needs. For example, in conditions ranging from +300°C to -40°C, we focus on achieving an optimal balance between sealing effectiveness and thermal adaptability. Our goal is to ensure both high-temperature resilience and low shrinkage at low temperatures.

We continue to explore new processes based on the principle of "pressure-responsive adaptability", a design philosophy that enables the packing structure to remain flexible and responsive to variations in pressure and temperature, rather than becoming rigid or unable to adjust after thermal cycling.

This is how we define a truly reliable graphite packing: not merely a sealing product from the manufacturer's perspective, but a purposefully engineered component with "responsiveness" that delivers safer, more stable performance in dynamic, real-world valve applications.

Send your message to this supplier

Related Articles from the Supplier

What is High-Temperature Ball Valve?

- Dec 23, 2025

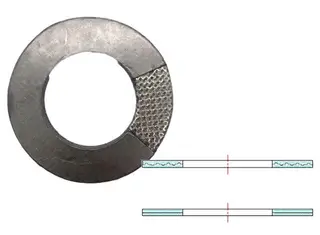

What are Reinforced Flexible Graphite Gaskets?

- Jun 13, 2025

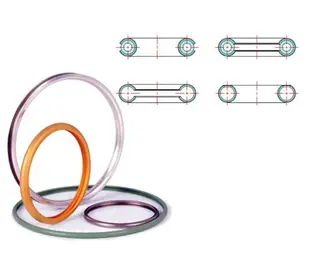

What are Metal C-Ring and O-Ring Gaskets?

- Jun 19, 2025

Related Articles from China Manufacturers

What Make Air Cooler a Popular Choice?

- May 25, 2024

What Makes the Forging Process Indispensable?

- Mar 29, 2024

What Makes Drop Forging Best for Industrial Metal

- Jan 08, 2025

Related Products Mentioned in the Article

Supplier Website

Source: https://www.magpievalves.com/media-hub/what-makes-a-good-low-emission-graphite-packing-our-view-and-process.html