A Guide to The Types of Ball Valves

A ball valve is one of the most universal and reliable components in fluid control systems today. They are widely used in industries such as oil and gas, power generation, and petrochemicals. The chemical processing industry is able to achieve tight closure, easy operation, and stable performance under harsh conditions.

The ball valve adopts a quarter turn rotating mechanism and a spherical closing element, which can achieve fast closing, minimal pressure drop, and long-term durability even in high-pressure or high-pressure environments. Their design also allows for automation in corrosive environments. Pneumatic or electric actuators are therefore very suitable for manual and remote control systems.

In this guide, we will explore the main types of ball valves, their internal mechanisms, and key factors to consider when choosing the appropriate valve for your industrial application.

What are the different types of ball valves?

The design purpose of a ball valve is to use a spherical closing element (usually referred to as a sphere) to rotate inside the valve body to control or stop fluid flow. When the spherical hole is aligned with the pipeline, the valve opens, allowing full flow to pass through. When rotated 90 degrees, the valve can be tightly closed with minimal leakage.

This simple and robust mechanism makes ball valves the preferred choice for industries such as oil and gas, petrochemicals, water treatment, and power generation that require reliable, fast closing, and precise control. Based on the support, sealing, and driving methods of the sphere, engineers can choose from several configurations optimized for different pressures, temperatures, and media.

Let us explore the most commonly used types of ball valves in modern industrial applications and understand the optimal application scenarios for each design.

1. Floating ball valves

The characteristic of a floating ball valve is that the ball is not fixed in place, but is secured in place by the valve seat. When pressure is applied, the steel ball will move downstream a bit, compressing the valve seat and forming a tight seal.

Key Features:

Simple structure and economical design.

Suitable for low to medium voltage applications

Compact and lightweight

Due to valve seat wear, its application is limited in large diameter or high-pressure systems.

Due to its reliable sealing performance and compact structure, float valves are commonly used in oil and gas pipelines, water treatment plants, and chemical systems. To better understand their comparison with other designs, please refer to our detailed guide on this topic.

2. Trunnion ball valves

An additional mechanical anchoring device called an ear shaft is also provided at the top and bottom of the ball body of an ear shaft ball valve. These components absorb pressure loads, thereby reducing the stress on the valve seat.

Advantages:

Suitable for high-pressure large-diameter pipelines

Reduce operating torque

Enhanced sealing performance

Longer service life under harsh conditions

This design is widely used in refineries, natural gas facilities, and petrochemical systems, where reliability and zero leakage are crucial.

As a ball valve manufacturer, we, Landee, provide 100% ear shaft ball valves that comply with API and EN standards and have been tested to ensure zero leakage performance.

3. Fully welded ball valves

The fully welded ball valve adopts a seamless and permanently welded valve body design, eliminating all potential leakage paths around the valve body joints and bolt connections. This structure enhances structural integrity and corrosion resistance, making it an ideal choice for long-term use in harsh environments.

Due to its leak proof and maintenance free design, fully welded ball valves are particularly important for underground, buried, or subsea pipeline installations, where accessibility is limited and reliability is crucial. It is commonly used in natural gas transportation areas for heating and oil pipeline systems, ensuring safe and uninterrupted transportation even under extreme pressure and temperature conditions.

Core functions:

Leak proof and corrosion-resistant welded body

Maintenance free design. It can be used for a long time.

Suitable for pipelines, oil and gas, and district heating systems

Capable of withstanding pressure fluctuations and environmental pressures

Landee's fully welded valves are designed specifically for critical energy and utility sectors, providing unparalleled durability and integrity even under extreme conditions.

4. Top goal valves

The top inlet ball valve allows maintenance or repair without removing the valve from the pipeline. The top cover can be disassembled for inspection or replacement of internal components.

Benefits:

Easy to maintain online

Suitable for high-voltage applications

It is common in the fields of oil refining, offshore operations, and power generation.

5. Side entry (split type) ball valves

A side entry ball valve, also known as a split valve, is composed of two or three assembled components connected by bolts. This modular design is easy to assemble and clean.

Advantages:

Manufacturing and maintenance are both very simple.

Provide two-piece or three piece designs

Suitable for general industrial use

6. V-shaped ball valves

The V-shaped ball valve adopts a V-shaped ball or valve seat, which can achieve precise flow control. This design does not use an on/off function, but allows for flow regulation through throttling.

Common applications:

Process control system

Chemical dosing system

Steam and slurry control

7. Multi-port ball valves

Multi-port valves (usually three-way or four-way valves) can divert fluid in multiple directions without the need for additional piping.

Typical use:

Process mixing and diversion

Cooling and heating system

Industrial automation equipment

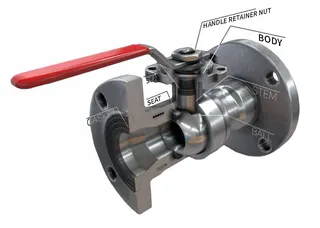

Understand the structure of ball valves

In addition to mechanical design and seat structure, the type of ball valve also depends on the construction of its internal flow channel, resulting in differences in configuration and function. These configurations will affect factors such as flow rate, pressure drop, sealing performance, and maintenance requirements.

Understanding these differences can help engineers choose the most effective valve layout for a specific system, whether it requires full flow, throttling accuracy, or multi-directional control.

Common configurations include the following points.

Full bore (full port): Same as the inner diameter of the pipeline, minimizing flow resistance to the greatest extent possible.

Shrinkage (standard port): a smaller spherical opening that is cost-effective for non-critical systems.

Segmented ball: optimized for throttling and flow regulation.

How to choose the appropriate type of ball valves?

When selecting ball valves for a system, several key factors that directly affect performance, safety, and long-term reliability must be considered. The correct choice depends on operating conditions, fluid characteristics, and installation requirements. Evaluating these aspects can ensure that the valve not only meets technical specifications, but also maintains stable efficiency throughout its entire service life.

Selection List:

Rated pressure and temperature of the system

Fluid type (liquid, gas, slurry, or corrosive medium)

Installation location (above ground, underground, or offshore)

Maintain the channel

Certification and standards (API, ISO, CE, EN)

Send your message to this supplier

Related Articles from the Supplier

A Guide to The Types of Ball Valves

- Dec 10, 2025

A New Development Force Boosts Valve Industry

- Oct 20, 2014

A Brief Introduction of Forged Steel Gate Valves

- Jan 21, 2021

Q&A of valve type selection (part one)

- Apr 04, 2019

Q&A of valve type selection (part two)

- Apr 08, 2019

Related Articles from China Manufacturers

A Guide to the Selection and Use of Valve

- Nov 08, 2024

How to Choose the Right Pump: A Comprehensive Guide

- Sep 20, 2025

Related Products Mentioned in the Article

XIAMEN LANDEE INDUSTRIES CO., LTD.

- https://www.landee.cn/

- Address: NO. 321 JIAHE ROAD, XIAMEN, P.R.CHINA 361012

- Phone: 86-592-5204188

- Business Type: Trading, Manufacturer,

Supplier Website

Source: https://www.landeevalve.com/a-guide-to-the-types-of-ball-valves.html