What Are Eccentric Reducers and Concentric Reducers?

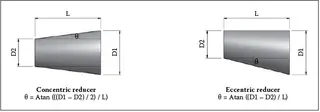

A pipe reducer is one of pipe fittings, which is used to joint pipes of different diameters. Generally, it is divided into the eccentric reducer and the concentric reducer. An eccentric reducer is a reducer whose center is not on the same straight line. Different from the eccentric reducer, the concentric reducer has a common center line. The commonly used forming process is diameter reduction pressing, diameter expansion pressing or diameter reduction plus diameter expansion pressing.

Application of the eccentric reducer

The diameter of the nozzle at both ends of the eccentric reducer is different. The reducer is used to connect pipes or flanges with different diameters. In other word, it can keep the small pipe and the big pipe together. It is generally used for vertical gas or liquid piping.

The eccentric reducer is generally used for horizontal liquid pipes. When the tangent point of the nozzle of the eccentric reducer is upward, it is called top flat installation, And this reducer is usually used for the pump inlet to prevent the build up of air bubbles. In contrast, when the tangent point is downward, it is called bottom flat installation. And this reducer is tend to be used for the installation of the regulating valve.

An eccentric reducer is beneficial to fluid flow, and has little interference to flow patterns during reducing. It is suitable for horizontal gas/vapor/steam piping. In those pipes, eccentric reducers must be installed with flat side down which allows condensed water or fluid to drain at low points.

Application of the concentric reducer

The concentric reducer is used for jointing the vertical liquid pipes of different sizes. The concentric reducer will not produce corrosion, pitting, rusting or wear, but can give full play to its good function and performance in the industry. A concentric reducer is also one of the metal materials with high strength for construction.

Application of the eccentric reducer

The diameter of the nozzle at both ends of the eccentric reducer is different. The reducer is used to connect pipes or flanges with different diameters. In other word, it can keep the small pipe and the big pipe together. It is generally used for vertical gas or liquid piping.

The eccentric reducer is generally used for horizontal liquid pipes. When the tangent point of the nozzle of the eccentric reducer is upward, it is called top flat installation, And this reducer is usually used for the pump inlet to prevent the build up of air bubbles. In contrast, when the tangent point is downward, it is called bottom flat installation. And this reducer is tend to be used for the installation of the regulating valve.

An eccentric reducer is beneficial to fluid flow, and has little interference to flow patterns during reducing. It is suitable for horizontal gas/vapor/steam piping. In those pipes, eccentric reducers must be installed with flat side down which allows condensed water or fluid to drain at low points.

Application of the concentric reducer

The concentric reducer is used for jointing the vertical liquid pipes of different sizes. The concentric reducer will not produce corrosion, pitting, rusting or wear, but can give full play to its good function and performance in the industry. A concentric reducer is also one of the metal materials with high strength for construction.

Send your message to this supplier

Related Articles from the Supplier

What Are Eccentric Reducers and Concentric Reducers?

- Aug 10, 2020

Related Articles from China Manufacturers

What are Eccentric Segmented Ball Valves?

- Aug 27, 2025

What Are the Major Future Trends of Valve Products?

- Sep 05, 2014

Related Products Mentioned in the Article

XIAMEN LANDEE INDUSTRIES CO., LTD.

- https://www.landee.cn/

- Address: NO. 321 JIAHE ROAD, XIAMEN, P.R.CHINA 361012

- Phone: 86-592-5204188

- Business Type: Trading, Manufacturer,

Supplier Website

Source: https://www.landeepipefitting.com/what-are-eccentric-reducers-and-concentric-reducers.html