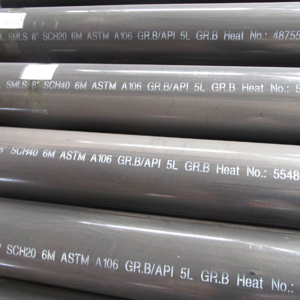

Requirements for the Quality of Seamless Steel Pipes

1. The chemical composition of steel

The chemical composition of steel is the most important factor affecting the performance of seamless steel pipes. It is also the main basis for formulating the process parameters of tube rolling and heat treatment of steel tubes. In the seamless steel pipe standard, corresponding requirements are put forward for the smelting of the steel and the manufacturing method of the pipe blank according to the different uses of the steel pipe. Strict regulations are made on the chemical composition. Certain harmful chemical elements such as arsenic, tin, antimony, lead and bismuth, and gases such as nitrogen, hydrogen and oxygen content are required in particular. In order to improve the uniformity of the chemical composition in the steel and the purity of the steel, reduce the non-metallic inclusions in the tube blank and improve its distribution, the molten steel is often refined by the refining equipment outside the furnace, and even the tube blank is remelted and refined by the electroslag furnace.

2. The geometric dimensional accuracy and outer diameter of the steel pipe

Accuracy of outer diameters, wall thickness, ovality, length, curvature of steel pipes, bevel angles and blunt edges of pipe end faces, cross-sectional sizes of special-shaped steel pipes

2. 1 Accuracy of outer diameters of steel pipes

The accuracy of the seamless steel pipe's outer diameter depends on the method of determining or reducing diameters (including tension reduction), the operation of the equipment, and the process system. Also, the outer diameter's accuracy is also related to the hole shape's machining accuracy of the sizing mill and the distribution and adjustment of the deformation amount of each rack. The accuracy of the outer diameter of the cold rolled seamless steel pipe is related to the accuracy of the die or rolling pass.

2. 2 Wall thickness

The wall thickness accuracy of the seamless steel pipe is related to the heating quality of the tube blank, the process design parameters and adjustment parameters of each deformation process, the quality of the tool and its lubrication quality. The uneven wall thickness of the steel pipe includes the uneven wall thickness in the transverse and longitudinal directions.

3. The surface quality of the steel pipe

The standard specifies the requirements for a smooth finish for steel pipes. However, there are as many as 10 surface defects for steel pipes due to various reasons in the production process, such as surface cracks of steel pipes, hair lines, inward folds, outward folds, punctures, delamination, scarring, pits, scratches, etc. On the one hand, these defects are mainly caused by the surface defects or internal defects of the tube blank. On the other hand, they are produced in the production process. If the rolling process parameters are unreasonably designed, the surface of the mold is not smooth, the lubrication conditions are not good, and the pass design and adjustment are unreasonable; they may lead to problems on the appearance of steel pipes. In the process of heating, rolling, heat treatment and straightening of the tube blank, if the heating temperature is not properly controlled, the deformation is uneven; the heating and cooling speed is unreasonable and the straightening deformation is too great. Cracks on the pipe surface will happen due to excessive residual stress.

4. Physical and chemical properties of steel pipes

The physical and chemical properties of steel pipes include mechanical properties at room temperatures, thermal strength or low-temperature performance at certain temperatures and corrosion resistance such as oxidation resistance, water corrosion resistance, acid and alkali resistance. Generally speaking, the physical and chemical properties of steel pipes mainly depend on the chemical composition, structure, purity, and heat treatment of the steel pipe. Of course, in some cases, the rolling temperature and deformation of the steel pipe also affect its performance.

5. Technical properties of steel pipes

The process properties of steel pipes include flattening, flaring, hemming, bending, ring pulling and welding of steel pipes.

6. Metallographic structure of steel pipes

The metallographic structure of the steel pipe includes the low magnification structure and the high magnification structure of the steel pipe.

7. Special requirements for steel pipes

Special conditions requested by the customer

The chemical composition of steel is the most important factor affecting the performance of seamless steel pipes. It is also the main basis for formulating the process parameters of tube rolling and heat treatment of steel tubes. In the seamless steel pipe standard, corresponding requirements are put forward for the smelting of the steel and the manufacturing method of the pipe blank according to the different uses of the steel pipe. Strict regulations are made on the chemical composition. Certain harmful chemical elements such as arsenic, tin, antimony, lead and bismuth, and gases such as nitrogen, hydrogen and oxygen content are required in particular. In order to improve the uniformity of the chemical composition in the steel and the purity of the steel, reduce the non-metallic inclusions in the tube blank and improve its distribution, the molten steel is often refined by the refining equipment outside the furnace, and even the tube blank is remelted and refined by the electroslag furnace.

2. The geometric dimensional accuracy and outer diameter of the steel pipe

Accuracy of outer diameters, wall thickness, ovality, length, curvature of steel pipes, bevel angles and blunt edges of pipe end faces, cross-sectional sizes of special-shaped steel pipes

2. 1 Accuracy of outer diameters of steel pipes

The accuracy of the seamless steel pipe's outer diameter depends on the method of determining or reducing diameters (including tension reduction), the operation of the equipment, and the process system. Also, the outer diameter's accuracy is also related to the hole shape's machining accuracy of the sizing mill and the distribution and adjustment of the deformation amount of each rack. The accuracy of the outer diameter of the cold rolled seamless steel pipe is related to the accuracy of the die or rolling pass.

2. 2 Wall thickness

The wall thickness accuracy of the seamless steel pipe is related to the heating quality of the tube blank, the process design parameters and adjustment parameters of each deformation process, the quality of the tool and its lubrication quality. The uneven wall thickness of the steel pipe includes the uneven wall thickness in the transverse and longitudinal directions.

3. The surface quality of the steel pipe

The standard specifies the requirements for a smooth finish for steel pipes. However, there are as many as 10 surface defects for steel pipes due to various reasons in the production process, such as surface cracks of steel pipes, hair lines, inward folds, outward folds, punctures, delamination, scarring, pits, scratches, etc. On the one hand, these defects are mainly caused by the surface defects or internal defects of the tube blank. On the other hand, they are produced in the production process. If the rolling process parameters are unreasonably designed, the surface of the mold is not smooth, the lubrication conditions are not good, and the pass design and adjustment are unreasonable; they may lead to problems on the appearance of steel pipes. In the process of heating, rolling, heat treatment and straightening of the tube blank, if the heating temperature is not properly controlled, the deformation is uneven; the heating and cooling speed is unreasonable and the straightening deformation is too great. Cracks on the pipe surface will happen due to excessive residual stress.

4. Physical and chemical properties of steel pipes

The physical and chemical properties of steel pipes include mechanical properties at room temperatures, thermal strength or low-temperature performance at certain temperatures and corrosion resistance such as oxidation resistance, water corrosion resistance, acid and alkali resistance. Generally speaking, the physical and chemical properties of steel pipes mainly depend on the chemical composition, structure, purity, and heat treatment of the steel pipe. Of course, in some cases, the rolling temperature and deformation of the steel pipe also affect its performance.

5. Technical properties of steel pipes

The process properties of steel pipes include flattening, flaring, hemming, bending, ring pulling and welding of steel pipes.

6. Metallographic structure of steel pipes

The metallographic structure of the steel pipe includes the low magnification structure and the high magnification structure of the steel pipe.

7. Special requirements for steel pipes

Special conditions requested by the customer

Send your message to this supplier

Related Articles from the Supplier

Requirements for the Quality of Seamless Steel Pipes

- Apr 16, 2022

Reasons for Cracking of Seamless Steel Pipes

- Jun 25, 2023

The correct selection of seamless carbon steel pipes

- Jul 08, 2020

Related Articles from China Manufacturers

Quality requirements for carbon steel pipes

- Aug 14, 2023

The Heat Treatment Process of Steel Pipes

- Jul 05, 2017

The Quality Testing Importance of Spiral Steel Pipes

- Apr 28, 2022

How to Detect the Quality of Spiral Steel Pipe

- Jul 11, 2023

Related Products Mentioned in the Article

XIAMEN LANDEE INDUSTRIES CO., LTD.

- https://www.landee.cn/

- Address: NO. 321 JIAHE ROAD, XIAMEN, P.R.CHINA 361012

- Phone: 86-592-5204188

- Business Type: Trading, Manufacturer,

Supplier Website

Source: https://www.landeepipe.com/requirements-for-the-quality-of-seamless-steel-pipes.html