Permanent Mold Casting vs. Sand Casting: A Detailed Comparison

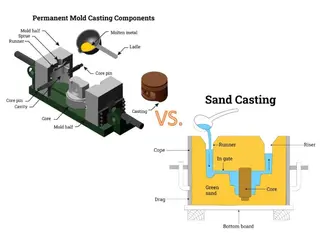

In the realm of manufacturing, casting technologies have always been a cornerstone for shaping metal components. Today, we will delve into a detailed comparison of two prevalent casting methods: Permanent Mold Casting and Sand Casting. Each method has its own strengths and is suited for different production scenarios and requirements. They exhibit significant differences in terms of technical principles, production efficiency, cost control, and casting quality.

Permanent Mold Casting: Efficiency and Precision

In the field of casting, Permanent Mold Casting stands out for its exceptional production efficiency and outstanding casting quality, making it an indispensable precision casting technology in modern manufacturing.

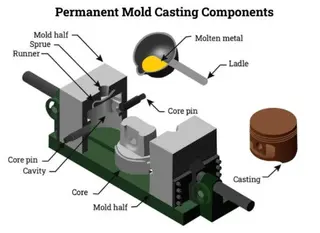

1. Principle of Permanent Mold Casting

Permanent Mold Casting, also known as hard mold casting, is a method where liquid metal is poured into a metal mold to obtain castings. This mold is made of metal and is highly durable, capable of being reused hundreds or even thousands of times. While there are certain limitations in terms of weight and shape for castings produced by Permanent Mold Casting, such as the production of simple-shaped castings for ferrous metals, with restrictions on casting weight and wall thickness, it offers significant advantages in production efficiency and casting quality.

2. Advantages of Permanent Mold Casting

Permanent Mold Casting boasts numerous technical and economic benefits. Firstly, castings produced by this method have higher mechanical properties compared to sand castings. For the same alloy, the tensile strength can be increased by an average of about 25%, the yield strength by about 20%, and there is a notable improvement in corrosion resistance and hardness. Secondly, the precision and surface finish of the castings are superior to those of sand castings, with stable quality and dimensions. Additionally, the process yield is higher, reducing the consumption of liquid metal by about 15–30%. Since little or no sand is used, there is a significant saving of molding materials, up to 80–100%. Moreover, the high production efficiency of Permanent Mold Casting reduces the causes of casting defects, simplifies the process, and is more conducive to mechanization and automation.

3. Limitations of Permanent Mold Casting

However, Permanent Mold Casting is not without its drawbacks. The high cost of mold manufacturing somewhat restricts its widespread application. The lack of permeability and flexibility of the metal mold can lead to defects such as insufficient pouring, cracking, or white mouth in cast iron pieces. During the Permanent Mold Casting process, factors such as the working temperature of the mold, the pouring temperature and speed of the alloy, the dwell time of the casting in the mold, and the type of coating used are highly sensitive to the quality of the casting and require strict control.

4. Cooling Technology

To ensure the stable quality of Permanent Mold castings and maintain normal production, it is crucial to maintain a constant temperature change in the metal mold during the production process. Therefore, after each pouring, the metal mold needs to be opened and left to cool until it reaches the specified temperature before the next pouring. If relying solely on natural cooling, the time required would be longer, reducing production efficiency. Hence, forced cooling methods are commonly used. The common forced cooling methods in Permanent Mold Casting include:

Air cooling, which involves blowing air around the metal mold to enhance convective heat dissipation. This method has a simple mold structure, is easy to manufacture, and has low cost, but the cooling effect is not ideal.

Indirect water cooling, where a water jacket is embedded in the back or a specific part of the metal mold. This method has better cooling effect than air cooling and is suitable for casting copper or malleable cast iron pieces. However, for thin-walled gray iron or ductile iron castings, intense cooling can increase casting defects.

Direct water cooling, where a water jacket is directly created on the back or a specific part of the metal mold, with water circulating inside for cooling. This method is mainly used for casting steel or other alloy pieces where strong cooling of the mold is required. Due to its high cost, it is only suitable for mass production. If the casting has a significant difference in wall thickness, it is also common to use a combination of heating and cooling in different parts of the metal mold to regulate the temperature distribution of the mold wall.

Sand Casting: Flexibility and Economy

In stark contrast to the efficiency and precision of Permanent Mold Casting, Sand Casting stands out for its high flexibility and economy, making it one of the widely used processes in the casting industry.

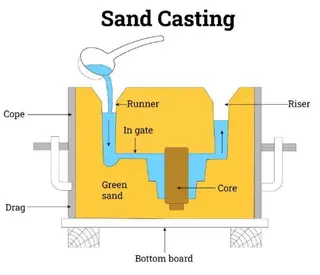

1. Principle of Sand Casting

Sand Casting is one of the common casting methods and is also a cost-effective casting method with low investment and production costs. Its process is simple and easy to operate, suitable for the manufacture of castings of various materials and sizes. First, the shape and size of the part to be cast are determined, and a reasonable casting plan is designed, including draft angle, fillet, and other pattern data. Then, according to the casting plan, suitable mold materials and sand with the appropriate grain size, as well as corresponding cores, are selected. The pattern is placed in the mold, and the corresponding sand material is filled in, compacted, and vibrated to ensure a perfect fit with the pattern, guaranteeing the accuracy of the casting. After the mold is opened and the pattern is removed, the two sand shells are assembled into a core, which is then placed in the correct position. The molten metal is poured into the sand mold until the entire cavity is filled. Once the casting has cooled and solidified, it is removed from the sand box and cleaned and trimmed.

2. Advantages of Sand Casting

The process of Sand Casting is simple and does not require special equipment, tools, or high technical skills, making it easy to learn and operate. It is cost-effective and has high production efficiency, suitable for single-piece and small-batch production, significantly reducing casting costs.

3. Challenges of Sand Casting

However, Sand Casting also has its limitations. Defects such as sand holes and gas pores can easily occur during the mold-making process, requiring repair and treatment. This not only affects the quality of the casting but also increases production time. Moreover, due to the limitations of the quality of the sand mold material and the number of cores, it is difficult to manufacture high-precision complex parts and is not suitable for the production of parts with high requirements for surface precision, strength, and density.

Performance Comparison Between Permanent Mold and Sand Casting

There are significant differences in performance between Permanent Mold and Sand Casting. Sand molds are permeable, while metal molds are not; sand molds have poor thermal conductivity, whereas metal molds have good thermal conductivity; sand molds are flexible, but metal molds are not. These characteristics determine different patterns in the casting formation process.

1. Gas State Changes in Mold Cavity and Casting Formation

During the Permanent Mold Casting process, when the metal fills the cavity, the gas inside the cavity must be quickly expelled. However, since the metal mold is impermeable, any slight negligence in the process can adversely affect the quality of the casting. In contrast, in Sand Casting, the permeability of the sand mold allows gases to be relatively easily expelled, reducing casting defects caused by residual gases.

2. Characteristics of Heat Exchange During Casting Solidification

Once the molten metal enters the cavity, it transfers heat to the metal mold wall. The liquid metal loses heat through the mold wall, solidifies, and contracts, while the mold wall, which gains heat and increases in temperature, expands. As a result, a "gap" forms between the casting and the mold wall. Before the "casting-gap-metal mold" system reaches the same temperature, the casting can be considered to be cooling in the "gap", while the metal mold wall is heated through the "gap". In Sand Casting, due to the poor thermal conductivity of the sand mold, the cooling speed of the casting is relatively slow, which to some extent affects the precision and surface finish of the casting.

3. The Impact of Metal Mold Restriction on Casting Contraction

During the solidification of the casting, the metal mold or core has no flexibility and restricts the contraction of the casting, which is another characteristic of Permanent Mold Casting. In contrast, Sand Casting, due to its flexibility, can better accommodate the contraction of the casting, reducing defects caused by contraction.

Application Scenarios and Selection Suggestions

After understanding the characteristics of permanent mold casting and sand casting, let's take a look at their respective application scenarios and how to make the right choice based on actual needs.

1. Application Scenarios for Permanent Mold Casting

Permanent Mold Casting is suitable for producing castings with simple shapes, moderate wall thickness, and moderate weight, especially when high requirements for mechanical properties, precision, and surface finish of the castings are needed. It is widely used in the automotive, aerospace, and mechanical manufacturing industries for producing key components such as engine blocks, cylinder heads, crankshafts, and connecting rods. These components need to withstand high-load, high-precision working environments, and Permanent Mold Casting can meet these requirements.

2. Application Scenarios for Sand Casting

Sand Casting is suitable for producing castings with complex shapes, uneven wall thickness, and large weight, especially when high requirements for production costs and efficiency are needed. It is widely used in the construction, mining, and agricultural industries for producing large castings such as cast iron pipes, cast iron manhole covers, and large steel castings. These castings have relatively low requirements for precision and surface finish but high demands for production costs and efficiency.

3. Selection Suggestions

When selecting a casting process, it is necessary to take into account various factors such as the shape, size, weight, precision requirements, surface finish requirements, production volume, and cost budget of the casting. If the casting requires high precision, high surface finish, high strength, and large production volume, Permanent Mold Casting is a better choice. If the casting has a complex shape, uneven wall thickness, small production volume, and high requirements for cost and production efficiency, Sand Casting may be a more suitable option.

Conclusion

Permanent Mold Casting and Sand Casting are two common casting processes, each with its own advantages and disadvantages, and are suitable for different production scenarios and requirements. Permanent Mold Casting, with its efficient and precise characteristics, has a significant advantage in producing high-precision, high-strength castings. Sand Casting, on the other hand, with its flexible and economical features, has a unique advantage in producing complex-shaped, small-batch castings. In actual production, it is necessary to select the appropriate casting process based on the specific requirements and production conditions of the casting to achieve the best production results.

Send your message to this supplier

Related Articles from the Supplier

What is Permanent Mold Casting?

- May 22, 2025

Related Articles from China Manufacturers

Related Products Mentioned in the Article

Supplier Website

Source: http://www.forging-casting-stamping.com/permanent-mold-casting-vs-sand-casting-a-detailed-comparison.html