Gravity Casting: Choice for Non-Ferrous Metal Casting

In modern manufacturing, casting technology has always been an important means of producing metal components. There are many types of casting processes, among which gravity casting holds a pivotal position in the field of non-ferrous metal casting due to its unique advantages and wide applications. This article will provide an in-depth discussion of the gravity casting process flow, advantages and limitations, as well as its applications in various industries, helping readers gain a comprehensive understanding of this efficient and economical casting technology.

Overview of Gravity Casting

Casting is a process in which metal is heated to a molten state and then poured into a mold to cool and solidify, thereby obtaining a casting with a specific shape and properties. According to the method of pouring molten metal, casting can be divided into gravity casting and pressure casting. Gravity casting is the process of pouring molten metal into a mold under the action of Earth's gravity, also known as free-flow casting. Pressure casting, on the other hand, is completed under external forces other than gravity.

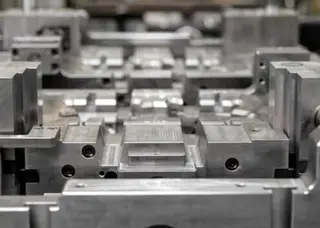

In a broad sense, gravity casting includes sand casting, permanent mold casting, investment casting, lost-foam casting, clay mold casting, and other forms; in a narrow sense, gravity casting specifically refers to permanent mold casting. Permanent mold casting is a process used to produce metal parts with complex shapes and fine details, and it is commonly used for casting aluminum and other non-ferrous metals. This process uses reusable metal molds, usually made of steel or iron, and preheated to a specific temperature. The mold consists of two halves clamped together to form a cavity in the shape of the desired part. The mold is designed with a gating and riser system to allow the molten metal to flow and vent during solidification.

Gravity Casting Process Flow

The gravity casting process flow is a systematic process involving multiple steps, each of which plays a crucial role in the quality of the final casting. From model making to post-processing of the casting, each step requires precise operation and strict quality control. The following will provide a detailed introduction to each stage of this process.

1. Model Making

The gravity casting process begins with model making. The model is a replica of the final desired part and is usually made of wood, plastic, or metal. The accuracy of the model is critical because it directly determines the shape and dimensions of the mold, thereby affecting the quality of the final casting. Model making requires precision and meticulousness to ensure that the mold can accurately reflect the features of the target part.

2. Mold Preparation

After the model is prepared, the next step is to prepare the mold. The mold is usually made of steel or sand and is divided into two halves. Before use, the mold must be thoroughly cleaned and coated with a release agent. The purpose of the release agent is to prevent the molten metal from sticking to the mold, facilitating smooth demolding of the casting. Proper application of the release agent can reduce the risk of casting defects and improve the surface quality and dimensional accuracy of the casting.

3. Mold Assembly

The two halves of the mold are firmly clamped together to form a sealed cavity. The mold is designed with a gating and riser system, which helps the molten metal flow smoothly and vent gas during solidification. Precise alignment and firm clamping of the halves are crucial to prevent molten metal leakage and ensure that the metal fills the cavity evenly and solidifies properly.

4. Mold Preheating

The assembled mold needs to be preheated to a certain temperature. The purpose of preheating is to reduce the temperature difference between the mold and the molten metal, thereby improving the metal’s fluidity and solidification. Appropriate preheating temperature helps enhance the quality and dimensional accuracy of the casting and reduces the occurrence of defects.

5. Metal Melting

Next, the metal (usually aluminum or other non-ferrous alloys) is heated and melted in a furnace or crucible. The metal must be heated to the appropriate casting temperature, which depends on the material used. Accurate temperature control and alloy composition are key to achieving ideal fluidity and preventing defects such as shrinkage or porosity. Once the molten metal reaches the target temperature, it is poured into a ladle or pouring basin and then gravity-fed into the mold cavity.

6. Pouring

The molten metal flows into the mold cavity under the force of gravity, filling it to form the desired shape. Proper pouring speed, correct gating design, and sufficient metal volume are key factors to ensure complete filling of the cavity. These factors help avoid turbulence, air entrapment, or splashing, thereby improving the quality of the casting.

7. Cooling and Solidification

After the molten metal fills the cavity, it gradually solidifies and forms the shape. The cooling process can be accelerated through internal cooling channels or water-cooled molds. Appropriate cooling time, well-designed cooling channels, and a controlled solidification process help achieve a uniform metal structure and dimensional accuracy, reducing defects such as cracks or shrinkage.

8. Mold Opening and Demolding

Once the casting has fully solidified and cooled, the mold can be opened. The two halves of the mold are separated to reveal the casting inside. Proper mold separation and demolding prevent damage to both the casting and the mold, ensuring smooth removal of the casting.

9. Post-Processing

After removal from the mold cavity, the casting may require further post-processing such as grinding, sandblasting, machining, or surface treatment. These post-processing steps improve the appearance, dimensional accuracy, and surface quality of the casting, meeting the final usage requirements.

Advantages of Gravity Casting

Gravity casting has several significant advantages, making it widely used in non-ferrous metal casting.

1. Production of Complex Shapes and Thin-Walled Parts

Gravity casting can produce parts with complex shapes, thin walls, and high dimensional accuracy. This process can precisely replicate the shape and details of the model, suitable for manufacturing metal parts with complex shapes and high precision requirements.

2. High Production Efficiency

Compared with other casting methods, gravity casting is relatively fast and efficient. It does not require complex equipment or high-pressure systems, operations are relatively simple, and production cycles are shorter, making it suitable for medium-to-high volume production.

3. Cost-Effectiveness

Gravity casting uses reusable metal molds with long service life and relatively low cost. This makes it an economical choice, especially suitable for medium-to-high volume production. In addition, gravity casting requires relatively low equipment investment and maintenance costs.

Limitations of Gravity Casting

Although gravity casting has many advantages, it also has some limitations.

1. Limitations for Complex Parts

Gravity casting is not well-suited for producing extremely complex or very small-featured parts. For such parts, more advanced casting processes such as die casting or precision casting may be required.

2. Labor and Time Costs

Compared with processes like die casting, gravity casting generally requires more manual operations and time. This may increase production costs and reduce production efficiency.

Common Materials for Gravity Casting

Gravity casting is commonly used for casting various non-ferrous metals, especially aluminum. Aluminum is widely used due to its low melting point, good fluidity, and excellent mechanical properties. Other non-ferrous metals can also be used in gravity casting.

1. Aluminum and Aluminum Alloys

Aluminum and its alloys are widely used in gravity casting because of their light weight, high strength-to-weight ratio, good corrosion resistance, and excellent thermal conductivity. Different aluminum alloy grades can be selected according to specific application requirements. Some alloys have higher strength, while others offer better corrosion resistance.

2. Copper Alloys

Copper-based alloys, such as brass and bronze, can also be gravity cast. These alloys have good electrical and thermal conductivity and excellent wear resistance, commonly used in applications requiring high strength, durability, and good thermal conductivity.

3. Zinc Alloys

Zinc alloys have excellent casting properties, including high fluidity, low melting point, and good dimensional accuracy. They also have good corrosion resistance and high strength, often used for decorative items or small mechanical parts requiring complex shapes or thin-walled structures.

4. Magnesium Alloys

Magnesium alloys have low density, high strength-to-weight ratio, good damping performance, and high thermal conductivity. Although gravity casting of magnesium alloys is not as widespread as aluminum, it is still used in applications requiring lightweight components with good mechanical properties, such as aerospace or automotive parts.

Applications of Gravity Casting

Gravity casting is widely used across multiple industries, especially in automotive, aerospace, and consumer goods.

1. Automotive Industry

In the automotive industry, gravity casting is widely used for producing engine components, transmission housings, wheel hubs, and other parts. These components often require complex shapes and high precision, which gravity casting can fulfill.

2. Aerospace Industry

The aerospace industry has extremely high requirements for the quality and precision of components. Gravity casting is used to produce critical aerospace components, such as engine parts and wing structures. These components require high strength, light weight, and excellent mechanical properties, which gravity casting can provide.

3. Consumer Goods Industry

In the consumer goods industry, gravity casting is used to produce various metal components, such as furniture hardware, lighting fixtures, and decorative items. These products often require good appearance and dimensional accuracy, which gravity casting can achieve.

Conclusion

Gravity casting is an efficient, economical, and widely used casting process. It can produce metal parts with complex shapes and high precision, particularly suitable for medium-to-high volume production. Although it has some limitations, gravity casting still plays an important role in industries such as automotive, aerospace, and consumer goods. By selecting materials appropriately and optimizing the process flow, gravity casting can produce high-quality castings to meet various industrial and consumer needs. With ongoing technological advancements, gravity casting will continue to improve and contribute to the development of modern manufacturing.

Send your message to this supplier

Related Articles from the Supplier

Related Articles from China Manufacturers

Gravity Casting Mold and Die Casting Mold

- Oct 27, 2016

Gravity Casting Mold and Die Casting Mold

- Mar 01, 2016

Gravity Casting Mold and Die Casting Mold

- Aug 13, 2019

Related Products Mentioned in the Article

Supplier Website

Source: http://www.forging-casting-stamping.com/gravity-casting-choice-for-non-ferrous-metal-casting.html