Casting Material Selection: How to Ensure High-Quality Parts

The craft of casting has been used since ancient times and remains particularly important in modern industry. Whether it is ancient bronze artifacts or today's automotive engines and aircraft components, they are all produced through casting. Simply put, casting involves melting metal into a liquid, pouring it into a mold, and letting it solidify, which allows for creating parts with complex shapes. However, to produce good cast parts, selecting the right material is especially crucial, as it directly determines how long the part can last and how it performs. This article discusses how to choose the right casting materials.

Common Casting Materials and Their Characteristics

There is a wide variety of casting materials, from inexpensive cast iron to advanced nickel-based alloys, each with its own capabilities and suitable applications. Understanding the characteristics of these materials is the first step to choosing the right one.

1. Cast Iron

Cast iron is one of the most commonly used materials in casting. Its advantage is that it can fill every corner of a mold, allowing the production of complex parts. Additionally, cast iron can absorb and dampen mechanical vibrations, which is important for equipment requiring stable operation. For example, the beds of machine tools and automobile engine blocks are well-suited for gray cast iron. Gray cast iron is low-cost and especially suitable for parts that bear pressure, require vibration damping, and wear resistance. Ductile iron is even more capable, with high strength and toughness, able to withstand complex stresses and impacts. Automotive crankshafts and bridge supports are excellent applications for ductile iron. This is because the spherical graphite structure inside ductile iron significantly enhances both strength and toughness.

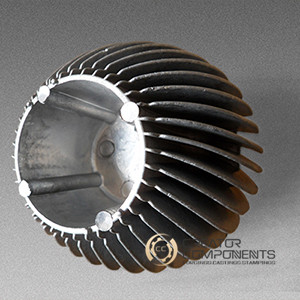

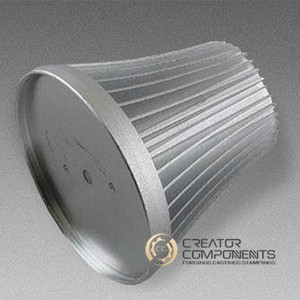

2. Aluminum Alloys

Aluminum alloys are lightweight, strong, and corrosion-resistant. They are widely used in aerospace, transportation, and other fields. For instance, airplane wings and automotive engine blocks made from aluminum alloys are both lightweight and high-performing. However, casting aluminum alloys requires strict process control; temperature and pouring speed must be precisely managed. If the temperature is too high or the pouring speed too fast, the casting can develop porosity and inclusions, affecting performance.

3. Copper Alloys

Copper alloys offer good electrical conductivity, thermal conductivity, and corrosion resistance, making them suitable for electrical components, pipes, and valves. During casting, controlling alloy composition and pouring temperature is important. Different alloying elements give copper alloys different properties. For example, adding zinc increases strength and hardness, while adding tin enhances corrosion resistance.

4. Stainless Steel

Stainless steel contains a high chromium content, offering excellent corrosion resistance and strength. It can be used in many applications, such as surgical equipment and electronic hardware. Adding more chromium and molybdenum further improves corrosion resistance. When casting stainless steel, process parameters must be strictly controlled to ensure uniform internal structure and stable performance.

5. Carbon Steel

Carbon steel is cost-effective, durable, and environmentally friendly. Its composition can be customized to meet different application requirements. Carbon steel has good machinability and weldability, and high toughness, making it widely used in mechanical manufacturing and structural applications. Its casting performance is good, meeting general casting requirements. Raw materials are widely available and low-cost, making it economical for large-scale production.

6. Nickel-Based Alloys

Nickel-based alloys have exceptional corrosion resistance and can combine with multiple elements to form different alloys with various properties. For example, high-nickel alloys are very stable in chemical processing applications. Casting nickel-based alloys involves complex process control; temperature, composition, and cooling rates must be precisely managed to ensure casting quality.

7. Copper-Based Alloys

Copper-based alloys have high corrosion resistance, with performance depending on alloy composition. For example, brass, an alloy of copper and zinc, has good machinability and corrosion resistance; bronze, an alloy of copper and tin or lead, has high strength and wear resistance. When casting copper-based alloys, alloy composition and pouring temperature must be carefully controlled.

Key Considerations for Selecting Casting Materials

Choosing casting materials not only determines the performance and lifespan of castings but also affects production cost and process feasibility. Therefore, material selection must comprehensively consider many key factors, including material performance characteristics, castability, the role of alloying elements, cost, and availability.

1. Understand Material Performance Characteristics

When selecting materials, it is necessary to understand their physical, chemical, and mechanical properties.

Physical properties: Density, melting point, and thermal conductivity affect the solidification process and dimensional accuracy. For example, low-density materials produce lighter parts; high-melting-point materials increase casting difficulty and cost; materials with good thermal conductivity help reduce hot cracking.

Chemical properties: Chemical composition affects corrosion resistance and mechanical properties. For example, chromium in stainless steel improves corrosion resistance; silicon in aluminum alloys enhances wear resistance.

Mechanical properties: Strength and toughness influence the lifespan and safety of the casting. High-strength materials can bear heavy loads, while high-toughness materials resist impact and fatigue failure.

2. Consider Material Castability

Castability is also important, including fluidity, shrinkage, and gas absorption.

Fluidity: Materials with good fluidity can fill fine mold details and produce more precise castings. For example, aluminum alloys have good fluidity and are suitable for complex automotive components; cast steel has poor fluidity and requires higher pouring temperature and pressure.

Shrinkage: Materials with low shrinkage reduce deformation and cracking during cooling. For example, cast iron has low shrinkage and is suitable for large castings; cast steel has higher shrinkage and requires measures to minimize deformation and cracking.

Gas absorption: Materials with low gas absorption reduce porosity and inclusions. For example, copper alloys have low gas absorption and produce high-quality castings; aluminum alloys have higher gas absorption and require strict gas control.

3. Choose Appropriate Alloying Elements

Alloying elements can change the structure and properties of the material to meet different requirements.

Increase strength and toughness: For example, adding manganese and silicon increases cast iron's strength and toughness; adding nickel and molybdenum improves cast steel's strength and toughness.

Improve conductivity and corrosion resistance: For example, adding copper increases aluminum alloy conductivity and corrosion resistance; adding chromium increases stainless steel corrosion resistance.

Enhance castability: For example, adding sulfur and phosphorus improves cast iron fluidity; adding aluminum and titanium improves aluminum alloy gas absorption.

4. Consider Cost and Availability

Material selection must also consider cost and availability.

Cost: Cast iron is low-cost and suitable for large-scale production; nickel-based alloys are expensive and suitable for small-batch, high-performance production. Selection should balance material value and batch size for cost-effectiveness.

Availability: Some materials are abundant and easily obtainable, while others may require import or special customization, increasing procurement cost and lead time. It is necessary to ensure materials are available on time, in the right quality, and in sufficient quantity.

Practical Case Studies

In the casting industry, proper material selection directly affects product quality and cost. Here are some real examples illustrating how to choose appropriate materials and processes.

1. Material Selection for Automotive Engine Blocks

Automotive engine blocks are critical components that must withstand high temperatures, high pressures, and complex stresses. When selecting materials, factors such as strength, toughness, thermal conductivity, and corrosion resistance must be considered. Aluminum alloys are an ideal choice; they are lightweight, strong, thermally conductive, and corrosion-resistant. Aluminum engine blocks not only reduce weight, improving fuel economy and performance, but also provide good heat dissipation, allowing engines to operate stably under high temperatures. During casting, temperature and pouring speed must be strictly controlled, using advanced processes such as high-pressure or low-pressure casting to minimize porosity and inclusions and improve casting quality.

2. Material Selection for Large Construction Machinery Components

Large construction machinery components, such as excavator arms and loader buckets, must bear heavy loads and complex stresses. Materials with high strength and toughness are required. Cast steel is a good choice due to its high strength and toughness, capable of handling heavy loads and complex stress conditions. Casting requires higher temperatures and stricter process control, using advanced methods such as sand casting or lost-foam casting to reduce defects, while carefully controlling composition to ensure stable performance.

Conclusion

Selecting casting materials is a particularly important step in casting processing. A deep understanding of material performance characteristics, castability, the role of alloying elements, cost, and availability is essential to choosing the right material for different casting requirements. In practice, all factors must be considered based on the specific use conditions and requirements of the casting to select cost-effective materials. Only by doing so can high-quality, high-performance parts be produced to meet the demands of modern industry.

Send your message to this supplier

Related Articles from the Supplier

Casting Technologies of Cast Steels

- Sep 05, 2014

Casting and Forging Used for Automobile Hub

- Aug 12, 2015

The Role of Temperature Control in Casting Process

- Mar 18, 2025

Influences of Cooling Intensity on Precision Casting

- Nov 09, 2015

Sand Casting: Process, Advantages and Challenges

- Feb 06, 2025

What is Centrifugal Casting Technology?

- Apr 17, 2025

Related Articles from China Manufacturers

Related Products Mentioned in the Article

Supplier Website

Source: http://www.forging-casting-stamping.com/casting-material-selection-how-to-ensure-high-quality-parts.html