Cast Iron: A Core Material in Industrial Manufacturing

On the vast stage of industrial manufacturing, cast iron plays an irreplaceable role with its unique properties and extensive applications. From ancient blacksmith forges to modern precision casting workshops, the use of cast iron has spanned the entire history of human industrial development. It not only supports traditional mechanical manufacturing but also plays a significant role in high-end fields such as automobiles, construction, and aerospace. This article will delve into the definition, classification, characteristics, production processes, and wide applications of cast iron in various industrial fields, revealing why cast iron stands out among numerous materials and becomes the cornerstone of industrial manufacturing.

Definition and Characteristics of Cast Iron

Cast iron is a type of iron-carbon alloy with a carbon content typically ranging from 2% to 4.3%. Due to its high carbon content, cast iron has good casting properties, enabling it to fill molds in a molten state at high temperatures to obtain castings with certain shapes and dimensions. The main characteristics of cast iron include:

Good casting properties: Cast iron has good fluidity, allowing it to form castings with precise shapes in complex molds.

Excellent mechanical properties: By adjusting the chemical composition and heat treatment processes, cast iron can achieve different mechanical properties, such as high strength, high toughness, and high wear resistance.

Low cost: Cast iron has abundant raw materials and relatively simple production processes, resulting in a low cost and high cost-effectiveness.

Good machinability: Cast iron has moderate hardness, making it easy to machine and suitable for manufacturing complex-shaped mechanical parts.

Classification of Cast Iron

There are many types of cast iron, which can be divided into gray cast iron, ductile cast iron, compacted graphite iron, and malleable cast iron based on their graphite morphology and matrix structure. In addition, there are special cast irons used to meet specific industrial needs.

1. Gray Cast Iron

Gray cast iron is the most common type of cast iron, with graphite distributed in flake form. This graphite morphology gives gray cast iron good casting and machinability properties, but it also reduces its strength and toughness. The main features of gray cast iron include:

Good casting properties: Gray cast iron has good fluidity, enabling it to fill complex molds and is suitable for manufacturing complex-shaped castings.

Good machinability: Gray cast iron has moderate hardness, making it easy to machine.

Lower strength and toughness: Due to the presence of graphite flakes, gray cast iron has relatively lower strength and toughness, but these properties can be improved by adjusting the chemical composition and heat treatment processes.

Gray cast iron is widely used in the mechanical manufacturing field, such as machine tool beds, engine blocks, and various housings. These parts usually bear lower loads and have lower requirements for strength and toughness.

2. Ductile Cast Iron

Ductile cast iron is a type of cast iron material with spherical graphite, obtained by treating molten iron with rare earth magnesium alloy. The strength and toughness of ductile cast iron are much higher than those of gray cast iron, approaching or even exceeding that of ordinary cast steel. The main features of ductile cast iron include:

High strength and toughness: The spherical graphite morphology of ductile cast iron reduces the cutting effect on the matrix, significantly improving the strength and toughness of the cast iron.

Good casting properties: Ductile cast iron has good fluidity, enabling it to fill complex molds.

Excellent wear resistance: Ductile cast iron has a higher hardness and good wear resistance.

Ductile cast iron is widely used in the automotive and mechanical manufacturing industries, such as automobile crankshafts, tractor transmission shafts, and rolling mill rolls. These parts usually bear higher loads and have higher requirements for strength and toughness.

3. Compacted Graphite Iron

Compacted graphite iron is a type of cast iron material with worm-like graphite, obtained by treating molten iron with rare earth magnesium alloy. Compacted graphite iron has higher strength and hardness, good wear resistance, and excellent thermal conductivity and thermal fatigue resistance. The main features of compacted graphite iron include:

High strength and hardness: The worm-like graphite morphology of compacted graphite iron reduces the cutting effect on the matrix, improving the strength and hardness of the cast iron.

Good wear resistance: Compacted graphite iron has a higher hardness and good wear resistance.

Excellent thermal conductivity and thermal fatigue resistance: Compacted graphite iron has good thermal conductivity and stable structure, making it suitable for parts used in high-temperature environments.

Compacted graphite iron is widely used in the automotive and mechanical manufacturing industries, such as automobile brake drums, internal combustion engine cylinder heads, and intake and exhaust manifolds. These parts usually work in high-temperature and wear environments and have higher requirements for wear resistance and thermal fatigue resistance.

4. Malleable Cast Iron

Malleable cast iron is an iron-carbon alloy with nodular graphite obtained by subjecting white cast iron to solid-state graphitization heat treatment (with or without decarburization). The main features of malleable cast iron include:

High strength and toughness: The nodular graphite morphology of malleable cast iron reduces the cutting effect on the matrix, improving the strength and toughness of the cast iron.

Good machinability: Malleable cast iron has moderate hardness, making it easy to machine.

Malleable cast iron is widely used in the automotive and mechanical manufacturing industries, such as automobile brake shoes and tractor track plates. These parts usually bear higher loads and have higher requirements for strength and toughness.

5. Special Cast Iron

Special cast iron refers to cast iron materials with special service properties, including wear-resistant cast iron, heat-resistant cast iron, and corrosion-resistant cast iron. Special cast iron is made by adding specific alloy elements to meet the special needs of different industrial fields.

Wear-resistant cast iron: Mainly used for manufacturing wear-resistant parts, such as grinding balls, grinding plates, and crusher hammers. The graphite morphology and matrix structure of wear-resistant cast iron have an important impact on its wear resistance.

Heat-resistant cast iron: Used for manufacturing parts that work in high-temperature environments, such as internal combustion engine cylinder heads, intake and exhaust manifolds, and high-temperature furnace components. Heat-resistant cast iron is made by adding alloy elements such as chromium, nickel, and molybdenum to improve its oxidation resistance and high-temperature strength.

Corrosion-resistant cast iron: Used for manufacturing parts that work in corrosive environments, such as chemical equipment and ship parts. Corrosion-resistant cast iron is made by adding alloy elements such as chromium, nickel, and copper to improve its corrosion resistance.

Melting and Casting Processes of Cast Iron

The melting and casting processes of cast iron have a crucial impact on its properties and quality. Since cast iron contains a large number of alloy elements, its melting and casting properties are significantly different from those of non-alloyed cast iron. Most alloy elements reduce the casting properties of cast iron, making it prone to various defects during the casting process, such as gas porosity, shrinkage porosity, and cracks. Therefore, it is necessary to take appropriate process measures based on the characteristics of various types of cast iron to ensure the quality of castings.

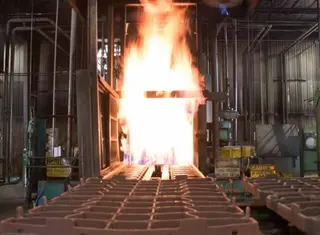

1. Melting Process

Melting is the first step in cast iron production, aiming to melt and mix various metal raw materials evenly to form an alloy melt with certain chemical composition and temperature. The key to the melting process is to control the melting temperature, time, and atmosphere to ensure the uniformity of alloy composition and the quality of the melt.

Melting equipment: Commonly used melting equipment includes cupola furnaces, electric arc furnaces, and induction furnaces. Cupola furnaces are suitable for melting cast iron, featuring high melting efficiency and low cost; electric arc furnaces and induction furnaces are suitable for melting various alloy steels and non-ferrous metal alloys, with the advantages of high melting temperature and precise composition control.

Melting process control: During the melting process, it is necessary to strictly control the melting temperature and time to prevent the burn-off of alloy elements and overheating of the melt. At the same time, the melting atmosphere should be controlled to avoid oxidation and gas absorption of alloy elements. For example, when melting high-chromium cast iron, it should be carried out in a reducing atmosphere to prevent the oxidation of chromium elements.

2. Casting Process

The casting process involves pouring the prepared alloy melt into a mold and forming a casting after cooling and solidification. The key to the casting process is to select appropriate mold materials and gating systems to ensure the quality and properties of the casting.

Mold materials: The choice of mold materials depends on the material and shape of the casting. Common mold materials include sand molds, metal molds, and ceramic molds. Sand molds are suitable for manufacturing complex-shaped and large-sized castings, featuring low cost and simple process; metal molds and ceramic molds are suitable for manufacturing small-sized castings with high precision requirements, with the advantages of high dimensional accuracy and good surface quality.

Gating system design: The design of the gating system has an important impact on the quality and properties of the casting. A reasonable gating system can ensure the smooth filling and solidification of the melt, preventing defects such as gas porosity, shrinkage porosity, and cracks in the casting. For example, when casting large cast iron parts, a complex gating system needs to be designed to ensure the uniform filling and solidification of the melt.

Application Fields of Cast Iron

Due to its excellent properties and wide applications, cast iron has become an indispensable material in modern industrial manufacturing. The following are specific applications of cast iron in different industrial fields:

1. Mechanical Manufacturing

Cast iron is widely used in mechanical manufacturing, mainly for manufacturing various mechanical parts. For example, gray cast iron is commonly used for manufacturing machine tool beds and engine blocks; ductile cast iron is used for manufacturing automobile crankshafts and tractor transmission shafts; compacted graphite iron is used for manufacturing automobile brake drums and internal combustion engine cylinder heads; malleable cast iron is used for manufacturing automobile brake shoes and tractor track plates.

2. Automotive Industry

The automotive industry is one of the main application fields of cast iron. Key components of automobiles, such as engine blocks, crankshafts, hubs, and brake drums, are mostly made of cast iron. For example, ductile cast iron crankshafts have high strength and good toughness, enabling them to withstand the high-load operation of engines; compacted graphite iron brake drums have good wear resistance and thermal fatigue resistance, making them suitable for work in high-temperature and wear environments.

3. Construction Industry

In the construction industry, cast iron is mainly used for manufacturing various building components and decorative materials. For example, cast iron drainage pipes and radiators are widely used in the water supply, drainage, and heating systems of buildings; cast iron railings and stair handrails are used for building decoration, featuring good aesthetics and durability.

4. Aerospace

The aerospace field has extremely high requirements for material properties, and cast iron also has certain applications in this field. For example, some heat-resistant cast irons are used to manufacture parts for high-temperature environments, such as certain components of engines. These cast irons are made by adding specific alloy elements to improve their oxidation resistance and high-temperature strength, meeting the special needs of the aerospace field.

Conclusion

Cast iron, a material with a long history, has occupied an irreplaceable position in modern industrial manufacturing due to its excellent casting properties, diversified mechanical properties, and relatively low cost. From gray cast iron to ductile cast iron, from compacted graphite iron to malleable cast iron, and to special cast iron, each type of cast iron has its unique properties and application scenarios, meeting the strict material requirements of different industrial fields. In the future, cast iron will continue to play an important role in industrial manufacturing, promoting technological innovation and industrial upgrading, and contributing more to the development of human industry.

Send your message to this supplier

Related Articles from the Supplier

Cast Copper Alloy Corrosion and Mechanisms

- Jan 03, 2025

Annealing Process of Cast Steel Components

- Sep 19, 2025

Casting Technologies of Cast Steels

- Sep 05, 2014

Related Articles from China Manufacturers

A brief introduction of a cast iron pipe

- Jul 04, 2018

Process and Technical Requirements of Cast Iron Tee

- Sep 08, 2020

Technical Requirements of Cast Iron Tee (Part Two)

- Dec 08, 2020

Nodular Cast Iron Pipe Fittings

- May 20, 2022

Introductions of Cast Iron Pipes

- Aug 31, 2017

Advantages of Cast Iron Valves

- Mar 28, 2024

Guide to Cast Iron Valve Surface Coating Processes

- Nov 20, 2025

Related Products Mentioned in the Article

Supplier Website

Source: http://www.forging-casting-stamping.com/cast-iron-a-core-material-in-industrial-manufacturing.html