Mastering Fastener Solutions for Demanding Environments

Fasteners play a pivotal role in diverse industries, with their performance requirements hinging on the unique challenges posed by different environmental conditions. We explores the multifaceted demands placed on fasteners in high-temperature, high-pressure, corrosive, extreme cold, and vibration-fatigue environments. This article delves into the specific properties and surface treatments imperative for ensuring the durability, reliability, and functionality of fasteners in these demanding scenarios.

Mastering the Heat: Fasteners in High-Temperature Environments

Pressure Points: Fasteners in High-Pressure Environments

Battling the Elements: Fasteners in Corrosive Environments

Cold Resistance: Fasteners in Extreme Cold Environments

Harmony in Motion: Fasteners in Vibration and Fatigue Environments

Fasteners, molded for high-temperature, high-pressure, corrosive, extreme cold, and vibration-fatigue realms, emerge as indispensable allies across diverse industries. The showcased scenarios highlight the significance of judicious fastener selection, emphasizing their role in project success and safety. A meticulous approach to choice, installation, and maintenance is essential for unlocking optimal fastener performance and durability in the face of formidable industrial challenges.

Mastering the Heat: Fasteners in High-Temperature Environments

1. Exceptional Characteristics: Fasteners in high-temperature domains, spanning power plants to aerospace, must endure elevated temperatures while retaining essential mechanical properties like strength, ductility, and resistance to creep.

2. Protective Coatings: Oxidation-resistant shields, such as aluminizing or chromium plating, become the armor that shields fasteners from oxidation in the crucible of high temperatures.

3. Application Showcase: Within jet engines, high-temperature alloy fasteners secure critical components, demonstrating resilience at temperatures surpassing 1000°C, ensuring sustained engine reliability and performance.

2. Protective Coatings: Oxidation-resistant shields, such as aluminizing or chromium plating, become the armor that shields fasteners from oxidation in the crucible of high temperatures.

3. Application Showcase: Within jet engines, high-temperature alloy fasteners secure critical components, demonstrating resilience at temperatures surpassing 1000°C, ensuring sustained engine reliability and performance.

Pressure Points: Fasteners in High-Pressure Environments

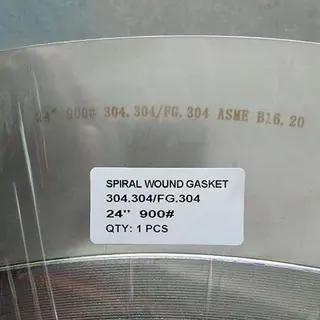

1.Resilient Features: Fasteners in high-pressure applications, including oil and gas, demand resilience through high-strength materials and sealing capabilities.

2. Corrosion Safeguards: Coatings with corrosion-resistant properties, from electroplating to PTFE applications, create a shield against corrosion, safeguarding fasteners in high-pressure settings.

3. Case in Point: In oil refineries, high-pressure alloy steel fasteners stand guard over flanges in high-pressure piping systems, ensuring a secure seal and uninterrupted refinery operations.

2. Corrosion Safeguards: Coatings with corrosion-resistant properties, from electroplating to PTFE applications, create a shield against corrosion, safeguarding fasteners in high-pressure settings.

3. Case in Point: In oil refineries, high-pressure alloy steel fasteners stand guard over flanges in high-pressure piping systems, ensuring a secure seal and uninterrupted refinery operations.

Battling the Elements: Fasteners in Corrosive Environments

1. Corrosion-Resistant Attributes: Fasteners navigating corrosive landscapes, from marine to chemical processing, demand corrosion-resistant materials and compatibility with diverse elements.

2. Protective Measures: Safeguards against corrosion, including electroplating and Dacromet applications, offer an impenetrable defense in hostile environments.

3. Illustrative Scenario: In seawater desalination plant construction, stainless steel fasteners combat corrosive saltwater, standing resilient to maintain plant functionality.

2. Protective Measures: Safeguards against corrosion, including electroplating and Dacromet applications, offer an impenetrable defense in hostile environments.

3. Illustrative Scenario: In seawater desalination plant construction, stainless steel fasteners combat corrosive saltwater, standing resilient to maintain plant functionality.

Cold Resistance: Fasteners in Extreme Cold Environments

1. Cold-Weather Durability: Fasteners in extreme cold settings, such as polar regions or aerospace applications, require materials resistant to low temperatures and the prevention of brittle fracture.

2. Freezing Safeguards: Coatings designed for low temperatures, featuring cryogenic-compatible lubricants, fortify fasteners against the chilling effects of extreme cold environments.

3. Case Exemplar: In satellite assembly, low-temperature-resistant fasteners defy the harsh cold of space, preserving strength and integrity in the frigid expanse.

2. Freezing Safeguards: Coatings designed for low temperatures, featuring cryogenic-compatible lubricants, fortify fasteners against the chilling effects of extreme cold environments.

3. Case Exemplar: In satellite assembly, low-temperature-resistant fasteners defy the harsh cold of space, preserving strength and integrity in the frigid expanse.

Harmony in Motion: Fasteners in Vibration and Fatigue Environments

1. Dynamic Resilience: Fasteners in dynamic environments, from automotive to heavy machinery, necessitate high-strength materials and fatigue resistance.

2. Vibration Control: Safeguards against loosening or failure induced by constant vibrations, such as dry film lubricants or thread-locking compounds, serve as protective measures.

3. Real-World Application: Within off-road vehicle suspension systems, high-strength steel fasteners, coupled with thread-locking compounds, endure vibrations, ensuring both performance and safety during challenging off-road adventures.

2. Vibration Control: Safeguards against loosening or failure induced by constant vibrations, such as dry film lubricants or thread-locking compounds, serve as protective measures.

3. Real-World Application: Within off-road vehicle suspension systems, high-strength steel fasteners, coupled with thread-locking compounds, endure vibrations, ensuring both performance and safety during challenging off-road adventures.

Fasteners, molded for high-temperature, high-pressure, corrosive, extreme cold, and vibration-fatigue realms, emerge as indispensable allies across diverse industries. The showcased scenarios highlight the significance of judicious fastener selection, emphasizing their role in project success and safety. A meticulous approach to choice, installation, and maintenance is essential for unlocking optimal fastener performance and durability in the face of formidable industrial challenges.

Send your message to this supplier

Related Articles from the Supplier

Related Articles from China Manufacturers

Solutions for Multi-Way Valves Failure

- Apr 16, 2015

Solutions for High-frequency Pipe Opening and Crack

- Aug 25, 2014

The Preferred Valve for Corrosive Environments

- Mar 05, 2021

Related Products Mentioned in the Article

XIAMEN QISHINE IMP.& EXP. CO., LTD.

- https://www.qishine.com/

- Address: NO.1 FENGZE YUAN,JINFENG LI,NO.17 JINSHENG LI,XIAMEN,CHINA

- Phone: +86 592 5255 951

- Business Type: Industry & Trading,

Supplier Website

Source: https://www.flangegasketboltkits.com/news/mastering-fastener-solutions-for-demanding-environments.html