How to Choose Carbon Dioxide Storage Tank Capacity?

In today's industrial and commercial sectors, the application of carbon dioxide is extremely widespread, covering multiple industries such as food and beverage, chemicals, and healthcare. Whether it is the carbonation process in breweries or the supply of medical gases in hospitals, carbon dioxide plays an indispensable role. In these application scenarios, the carbon dioxide storage tank, as the core equipment for storing and supplying carbon dioxide, is of vital importance in terms of capacity selection. It is not only related to operational costs and storage efficiency, but also closely connected with production safety and business continuity. This article will delve into how to reasonably select the capacity of a carbon dioxide storage tank to ensure that enterprises can use carbon dioxide safely and efficiently.

The Purpose of Carbon Dioxide Storage Tanks

Carbon dioxide storage tanks are the main containers for storing carbon dioxide, and their uses are extensive and significant. In hospitals, they provide high-purity medical carbon dioxide for operating rooms and wards; in food factories, they are used for the production of carbonated beverages and the preservation of food; in steel mills, they are used for metal cutting and welding. Compared with traditional steel cylinders, carbon dioxide storage tanks offer higher safety and cost-effectiveness. They can effectively reduce the operational costs of enterprises and improve work efficiency, which is why their usage rate has been increasing in recent years.

Structural Design of Carbon Dioxide Storage Tanks

The tank body of a carbon dioxide storage tank usually adopts a double-layer container structure, with an inner and an outer container. The materials of the inner and outer containers are different. The inner container is typically made of low-temperature-resistant stainless steel, while the outer container is made of high-strength carbon steel. After a series of processes such as sandblasting on the tank surface, a special coating is applied to enhance corrosion resistance. The space between the inner and outer containers is evacuated and filled with insulating material, with perlite being the most common. This design can effectively reduce heat transfer and maintain the low-temperature liquid state of carbon dioxide.

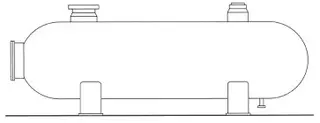

Carbon dioxide storage tanks come in two forms: vertical and horizontal, and can be selected according to actual needs. Vertical tanks have a small footprint and are suitable for places with limited space; horizontal tanks are more convenient for transportation and installation. To maintain the low-temperature state of carbon dioxide, the tanks are also equipped with refrigeration equipment inside. When the temperature exceeds the set limit, the refrigeration machine will automatically start to ensure that the carbon dioxide inside the tank remains below the specified temperature.

Considerations for CO2 Storage Tank Capacity Selection

In many industries involving the storage and use of carbon dioxide, choosing the right capacity for a carbon dioxide storage tank is a crucial decision point. It is not only related to cost and efficiency but also to safety and the stable operation of the business. So, what factors do we need to focus on? Next, we will discuss in detail the key factors in selecting the tank capacity.

1. Short-term and Long-term Usage

When selecting the capacity of a carbon dioxide storage tank, it is first necessary to accurately calculate the short-term usage of carbon dioxide. Taking the food and beverage industry as an example, breweries need a large amount of carbon dioxide for carbonation and preservation during the brewing and canning processes of beer. Suppose a brewery produces 100,000 bottles of beer per day, and each bottle requires 5 grams of carbon dioxide to be injected, then the daily usage of carbon dioxide is 500 kilograms. By calculating the daily and weekly beer production, as well as the amount of carbon dioxide consumed for a certain quantity of beer produced, the total short-term demand for carbon dioxide can be determined.

In addition to short-term usage, long-term usage trends should not be overlooked. As a company's business grows, product output may gradually increase. For example, a chemical enterprise in the expansion phase may see its carbon dioxide usage rise year by year with the introduction of new production lines. Therefore, it is necessary to analyze the growth trend of carbon dioxide usage by forecasting the company's production plans and market demands over the next few years, and to reserve some capacity for the tank selection to avoid frequent equipment replacement due to insufficient tank capacity, which would increase costs.

2. Usage Frequency

Usage frequency also affects the selection of tank capacity. If the usage frequency is high, such as in the fresh food section of some large supermarkets, where carbon dioxide needs to be continuously injected into the refrigerated display cabinets to maintain the freshness of fresh food, a larger capacity tank is required to reduce the frequency of gas replenishment and ensure stable supply. On the contrary, if the usage frequency is low, such as in some small laboratories that occasionally conduct experiments requiring carbon dioxide, a smaller capacity tank can meet the demand.

3. Storage Conditions

The physical state and storage density of carbon dioxide change under different pressure and temperature conditions. At normal temperature and pressure, carbon dioxide is in a gaseous state, but it can be transformed into a liquid state under certain pressure and low temperature. The storage density of liquid carbon dioxide is much greater than that of gaseous carbon dioxide, which can effectively save tank space. For example, in industry, carbon dioxide is usually pressurized to 5 - 7 megapascals and cooled to around -20℃ to be stored in a liquid state. Therefore, when selecting the tank capacity, the storage state of carbon dioxide should be considered, and the required storage space should be accurately calculated based on the density under the actual storage pressure and temperature conditions.

4. Loss Factors

During storage, there will inevitably be some loss of carbon dioxide, such as minor leakage due to poor valve sealing. In addition, when the tank is being filled and gas is being discharged, some gas will remain. Therefore, when calculating the tank capacity, these loss factors should be taken into account, and a certain amount of extra capacity should be added to ensure that the tank can still meet the actual usage requirements under normal loss conditions. At the same time, the replenishment cycle and method of carbon dioxide should be clarified to reasonably arrange the remaining capacity of the tank.

5. Regulatory Requirements

Different industries and regions have strict regulatory requirements for the installation and use of carbon dioxide storage tanks. In the medical industry, tanks used to store medical carbon dioxide must comply with relevant medical device regulatory standards in terms of capacity, material, and safety protection devices. For example, it is required that the tanks have high-precision pressure monitoring and alarm devices to ensure the safety of medical gas usage. In the chemical industry, chemical safety regulations must be followed, with clear stipulations on the capacity, spacing, and fire and explosion prevention measures of the tanks. When selecting tank capacity, enterprises must strictly comply with these regulatory requirements to avoid penalties and safety risks due to non-compliance.

6. Safety Margin

From a safety perspective, the tank capacity should not be completely filled, and a certain safety space should be reserved to cope with possible pressure fluctuations and temperature changes. Generally, the safety margin is usually 5% - 10% of the total tank capacity. For example, for a carbon dioxide storage tank with a design capacity of 10 cubic meters, the actual effective capacity for storing carbon dioxide should be controlled between 9 - 9.5 cubic meters, with the remaining space used to buffer pressure changes and prevent safety accidents such as tank rupture due to excessive pressure.

Case Analysis

After discussing the key factors in selecting the capacity of a carbon dioxide storage tank, let's further understand how to apply these factors to practical scenarios through specific cases.

1. Carbon Dioxide Storage Tank for a Brewery

Taking a medium-sized brewery as an example, the brewery produces 100,000 bottles of beer per day, and each bottle requires 5 grams of carbon dioxide to be injected, with a daily carbon dioxide usage of 500 kilograms. According to the production plan, the output will increase by 10% year by year over the next three years. Considering the high usage frequency and the need for continuous carbon dioxide supply, as well as to deal with losses and safety margins, a horizontal carbon dioxide storage tank with a capacity of 5 cubic meters was finally selected. The tank is equipped with efficient refrigeration equipment and a dual safety system to ensure stable and safe carbon dioxide supply during the production process.

2. Carbon Dioxide Storage Tank for a Hospital

In the medical industry, a large hospital needs to store medical carbon dioxide for operating rooms and wards. According to the hospital's usage statistics, 100 kilograms of medical carbon dioxide are required daily. Considering the low usage frequency but the extremely high requirements for safety and purity, a vertical carbon dioxide storage tank with a capacity of 2 cubic meters was finally selected. The tank complies with medical device regulatory standards and is equipped with high-precision pressure monitoring and alarm devices to ensure the safety and reliability of medical gas usage.

Conclusion

Reasonably selecting the capacity of a carbon dioxide storage tank is a complex but crucial task. It requires a comprehensive consideration of various factors such as short-term and long-term usage, usage frequency, storage conditions, loss factors, regulatory requirements, and safety margins. By accurately calculating and scientifically forecasting, combined with the actual needs of the application scenarios, choosing the right tank capacity can not only improve storage efficiency and reduce operating costs, but also ensure production safety and business continuity. When selecting a tank, attention should also be paid to its safety performance and ease of operation, and high-quality products that meet industry standards should be chosen. Only in this way can enterprises ensure that the use of carbon dioxide is both safe and efficient, achieving sustainable development.

Send your message to this supplier

Related Articles from the Supplier

How to Choose Carbon Dioxide Storage Tank Capacity?

- Aug 18, 2025

How to Choose Pressure Gauges for Pressure Vessels

- Apr 14, 2025

Related Articles from China Manufacturers

How to Choose the Right Carbon Dioxide Sensor

- Dec 29, 2023

How to choose locks for doors?

- Jun 27, 2018

How to Choose a Weatherproof Lock for Base Stations?

- Dec 14, 2021

How to Choose Swimming Equipment?

- Aug 07, 2020

How to Choose the Swimsuit for a Model?

- Jan 12, 2021

How to Choose the Appropriate Forged Valve?

- May 17, 2024

How to Choose Regulating Valve?

- Sep 23, 2016

Related Products Mentioned in the Article

topper

- www.chinatopper.com

- Address: Xiamen

- Phone: 86-592-5819200

- Business Type: Trading, Industry & Trading, Manufacturer,

Supplier Website

Source: https://www.fabtank.com/news/how-to-choose-carbon-dioxide-storage-tank-capacity.html