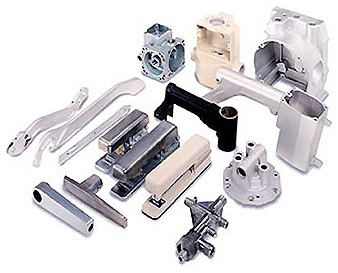

The Time Control of Die Casting

The time of die casting process means fill time, pressurized time, holding time and retention time. These times are comprehensive results from various aspects, including three factors, pressure, speed and temperature, then coupled with the physical properties of molten metal, the casting structure (especially wall thickness), the mold structure (especially the gating and overflow system). Time is a multiple factor, but it is closely related to those factors above. Therefore, time is very important for die cast process.

1. Fill time

Fill time means that the molten metal started to enter the cavity under pressure until the cavity was full.

The filling time is a result of combination of pressure, speed, temperature, mold gating and overflow system, alloy properties and casting structure (wall thickness). Thus, it is also a comprehensive reflection of the degree of intercoordination of various factors in the filling process.

The fill time should base on that the molten metal has not solidified and filled out. The following table is the choose of fill time:

1. Fill time

Fill time means that the molten metal started to enter the cavity under pressure until the cavity was full.

The filling time is a result of combination of pressure, speed, temperature, mold gating and overflow system, alloy properties and casting structure (wall thickness). Thus, it is also a comprehensive reflection of the degree of intercoordination of various factors in the filling process.

The fill time should base on that the molten metal has not solidified and filled out. The following table is the choose of fill time:

| The average wall thickness of the die casts | Fill time | The average wall thickness of the die casts | Fill time |

| 1 | 0.010-0.014 | 5 | 0.048-0.072 |

| 1.5 | 0.014-0.020 | 6 | 0.056-0.084 |

| 2 | 0.018-0.026 | 7 | 0.066-0.100 |

| 2.5 | 0.022-0.032 | 8 | 0.076-0.116 |

| 3 | 0.028-0.040 | 9 | 0.088-0.138 |

| 3.5 | 0.034-0.050 | 10 | 0.100-0.160 |

| 4 | 0.040-0.060 | ||

We should also consider the following situations for time selections:

① When alloy pouring temperature is high, the filling time can be longer.

② When the mold temperature is high, the filling time should be longer.

③ The wall of die cast is far from the inner gate, the filling time is ought to be longer.

④ Alloys which have high melting latent heat and specific heat , fill time should be longer.

2. pressurized time

The pressurized time is the pressurized phase of molten metal during the filling process, starting from the instantaneous filling of the cavity till the boost pressure reaches a predetermined value.

That is, the time required for the injection pressure rise to pressurized pressure.

3. Holding time

The time when the molten metal is solidified under the pressurized pressure after the molten metal is filled with the cavity is called the holding time. The role of holding is that injection plunger passes pressure to the cavity through the remaining material which has not yet solidified and the metal which is in the gating part, so as to crystallize the metal which is solidifying under the high pressure and gain compact casts.

The choosing of holding time is considered by the following factors:

① Die casting alloy characteristics: die casting alloy crystal has a wide crystallized range, the holding time should be longer.

② Casting wall thickness: the average cast wall thickness is big, the holding time can be longer.

③ Pouring system: When the inner gate is thick, the holding time can be longer.

The regular specific pressure

| alloy | Wall thickness of die casts (mm) | |

| <2.5 | 2.5-6 | |

| Zinc alloy | 1-2 | 3-4 |

| Aluminum alloy | 1-2 | 3-5 |

| Magnesium alloy | 1-2 | 3-5 |

| Copper alloy | 2-3 | 5-7 |

Send your message to this supplier

Related Articles from the Supplier

The Time Control of Die Casting

- Aug 13, 2019

The Precision and Durability of Moulds

- Aug 13, 2019

The Foremost Market of Fastener is Automobile

- Aug 13, 2019

The Die Cast Technology of Ferrous Metals

- Aug 13, 2019

Related Articles from China Manufacturers

The Time Control of Die Casting

- Mar 17, 2017

The Best Time to Choose A Gate Valve

- Oct 23, 2024

When is the Best Time to Charge Your Electric Car?

- Nov 21, 2024

Related Products Mentioned in the Article

topper

- www.chinatopper.com

- Address: Xiamen

- Phone: 86-592-5819200

- Business Type: Trading, Industry & Trading, Manufacturer,

Supplier Website

Source: https://www.die-castings.com/the-time-control-of-die-casting.html