Advantages and Applications of Ductile Iron Valves

Ductile iron valves have become an indispensable component in modern industry due to their superior performance and extensive applications. These valves not only possess high strength and toughness but also exhibit excellent corrosion resistance and vibration damping capabilities, enabling them to perform exceptionally well in various fields such as water supply and drainage, heating, ventilation and air conditioning (HVAC), and fire protection. In the medium and low-pressure valve market, ductile iron valves have gained popularity among numerous engineers and designers for their cost-effectiveness and reliability. Today, we will delve into the unique advantages of ductile iron and its wide range of applications.

Characteristics of Ductile Iron

Ductile iron is a special type of cast iron material, characterized by its spherical graphite structure. This unique structure endows ductile iron with many excellent properties. Compared with ordinary cast iron, ductile iron has a higher carbon content, typically above 3%. In contrast, cast steel has a relatively lower carbon content, usually less than 0.3%. The difference in carbon content leads to different internal structures of the materials, which in turn affects their properties.

In ordinary cast iron, carbon exists in the form of free graphite flakes. These flakes act as sources of cracks within the material, resulting in poor toughness and a tendency to break easily. However, in ductile iron, through a special treatment process, the graphite flakes are transformed into tiny spheres. These spherical graphite particles do not initiate cracks like flakes; instead, they can prevent the propagation of cracks, hence the term "crack terminator." This unique microstructure makes ductile iron superior to ordinary cast iron and cast steel in terms of strength, toughness, and impact resistance.

Performance Advantages of Ductile Iron Valves

Let's now explore the outstanding performance of ductile iron valves in practical use, which is the key to their standing out among various valve materials.

1. Strength and Toughness

Ductile iron has excellent tensile and yield strengths. Its tensile strength can reach 60k, and the yield strength is 40k, far higher than the 31k tensile strength of ordinary cast iron, which has no yield strength. Compared with cast steel, ductile iron also has a higher yield strength, with a minimum of 40k, while cast steel's yield strength is only 36k. This means that under the same load, ductile iron valves can better resist deformation and damage.

Moreover, the yield-to-tensile strength ratio (yield strength to tensile strength ratio) of ductile iron is 0.6 to 0.65, while that of cast steel is only 0.5 to 0.55. This indicates that ductile iron is more efficient in utilizing material strength and can fully exert its mechanical properties. In practical applications, this means that ductile iron valves can achieve higher strength and reliability with smaller size and weight.

2. Corrosion Resistance

The corrosion resistance of ductile iron is also very good. Due to the spherical form of its internal graphite and high chemical stability, in weakly corrosive environments, such as ordinary urban water supply and drainage systems, ductile iron valves can resist the erosion of dissolved oxygen and trace amounts of acidic and alkaline substances in water. In contrast, cast steel has a lower carbon content but a higher manganese content. Manganese has poor stability, is prone to rusting, and can form flaky scaling, so it is not as corrosion-resistant as ductile iron.

In some special application scenarios, such as sewage treatment systems, after being treated with anti-corrosion paint, ductile iron valves can be used for a long time in sewage containing corrosive substances such as sulfides. This surface treatment method further enhances the corrosion resistance of ductile iron valves, enabling them to maintain good performance in harsh environments.

3. Cost-effectiveness

In addition to performance advantages, the cost-effectiveness of ductile iron is also one of the important reasons for its widespread application in valve manufacturing. Compared with cast steel, ductile iron has a lower manufacturing cost, higher casting efficiency, and relatively lower machining cost. This makes ductile iron valves more cost-effective in the market and provides users with a more economical choice.

Application Scenarios of Ductile Iron Valves

The reason why ductile iron valves are so popular in the market is not only due to their excellent performance but also their wide range of applications. After understanding the performance advantages of ductile iron valves, it is natural to wonder how these advantages are reflected in practical applications.

1. Water Supply and Drainage Systems

In water supply and drainage systems of buildings, factories, and municipal projects, ductile iron valves are an ideal material choice. These systems usually require valves to have good corrosion resistance and certain strength to cope with chemical substances in water and pressure fluctuations. The corrosion resistance and high strength of ductile iron valves enable them to meet these requirements, and their cost-effectiveness also makes them a cost-effective choice.

In water supply and drainage systems, the working conditions of valves are relatively mild, with medium temperatures generally ranging from ambient temperature to around 100℃ and nominal pressures mostly not exceeding 1.6MPa. The temperature range of ductile iron valves is -30℃ to 350℃, which can fully meet these requirements. In addition, the high hardness of ductile iron can resist the wear of solid particles in water on the valve surface, thereby extending the service life of the valve.

2. HVAC and Fire Protection Systems

In HVAC and fire protection systems, valves need to withstand certain pressure and temperature changes. The high strength and good corrosion resistance of ductile iron valves enable them to adapt to the working conditions of these systems. For example, in fire protection systems, valves need to work normally in high-temperature and high-pressure environments. The temperature range and strength of ductile iron valves can meet these requirements, ensuring the reliability and safety of valves in emergencies.

3. Chemical and Industrial Environments

In chemical and industrial environments, valves need to withstand more complex chemical substances and higher pressures. Although the corrosion resistance of ductile iron valves is relatively weak in strongly corrosive environments, their corrosion resistance can be significantly improved through appropriate surface treatments such as painting and galvanizing. In addition, the high strength and toughness of ductile iron enable it to withstand certain pressures and impact forces, making it suitable for medium and low-pressure pipeline systems.

In some high-wear application scenarios, such as the transportation of fluids containing a large amount of solid particles, the wear resistance of ductile iron valves is acceptable. However, compared with high-hardness carbon steel valves, there is still a gap in wear resistance. In these cases, carbon steel valves that have undergone appropriate heat treatment may be more suitable because they can better resist the erosion of solid particles.

Comparison of Ductile Iron Valves and Carbon Steel Valves

In this section, we will conduct a comprehensive comparison of ductile iron valves and carbon steel valves, analyzing their respective advantages and disadvantages from multiple dimensions such as strength, corrosion resistance, and cost-effectiveness.

1. Strength and Toughness

Ductile iron valves and carbon steel valves each have their own strengths in terms of strength and toughness. Ductile iron valves have higher yield strength and tensile strength, enabling them to maintain good performance under higher loads. Carbon steel valves, on the other hand, have a higher elongation rate and better toughness, allowing them to better resist external impact forces. The choice of material in practical applications depends on specific working conditions and requirements.

2. Corrosion Resistance

In terms of corrosion resistance, ductile iron valves and carbon steel valves also show different performances. Ductile iron valves have better corrosion resistance in weakly corrosive environments, but may require additional surface treatment in strongly corrosive environments. Carbon steel valves are prone to corrosion without protective treatment, but their corrosion resistance can be greatly improved through appropriate anti-corrosion treatments such as applying anti-corrosion coatings, using anti-corrosion linings, or undergoing passivation treatment.

3. Cost-effectiveness

From the perspective of cost-effectiveness, ductile iron valves are generally more cost-effective than carbon steel valves. The manufacturing cost of ductile iron is lower, the casting efficiency is higher, and the machining cost is also relatively lower. This makes ductile iron valves more cost-effective in the market and provides users with a more economical choice. In contrast, the manufacturing cost of carbon steel valves is higher, especially after special anti-corrosion treatment, the cost will increase further.

Conclusion

Ductile iron valves stand out in many industrial applications with their excellent mechanical properties, corrosion resistance, and cost-effectiveness. Their high strength and toughness enable them to withstand higher loads and pressures, and their good corrosion resistance allows them to maintain good performance in various environments. Cost-effectiveness gives them a higher cost-performance ratio in the market. Whether in water supply and drainage systems, HVAC and fire protection systems, or chemical and industrial environments, ductile iron valves can meet the needs of users and provide reliable solutions. In summary, ductile iron valves are an excellent industrial material with superior performance and wide application. They not only meet current engineering needs but will also continuously expand their application fields through technological innovation. Choosing ductile iron valves means choosing a reliable, economical, and efficient solution.

Send your message to this supplier

Related Articles from the Supplier

Advantages and Applications of Ductile Iron Valves

- Aug 27, 2025

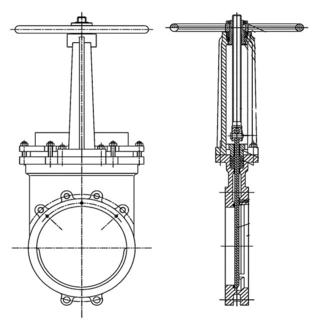

Functions and Advantages of Knife Gate Valves

- Mar 04, 2024

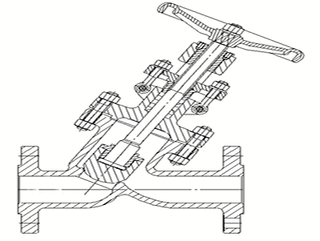

Design and Advantages of Bellows Sealed Globe Valve

- Jul 31, 2024

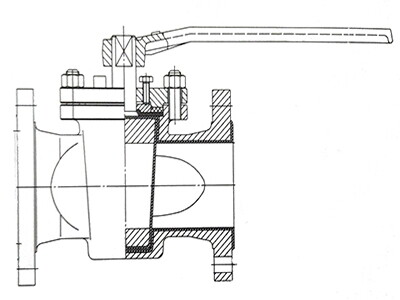

The Advantages of Ball Valves with Balance Holes

- Oct 12, 2024

Related Articles from China Manufacturers

Advantages and Applications of Ductile Iron Valves

- Feb 12, 2025

Advantages and Applications of Ductile Iron Valves

- Aug 27, 2025

Related Products Mentioned in the Article

- https://www.bossealvalves.com/

- Address: Suzhou, Jiangsu, China

- Phone: 13358051997

- Business Type: Industry & Trading,

Supplier Website

Source: https://www.bossealvalves.com/news/advantages-and-applications-of-ductile-iron-valves.html