Industry Definition & Scope

The gate valves industry involves the design, manufacturing, and application of linear-motion valves that control fluid flow by raising or lowering a solid gate (wedge or parallel disc) perpendicular to the flow direction. Renowned for their straight-through flow characteristics and tight shutoff capabilities, gate valves serve as primary isolation valves in critical industrial systems where minimal pressure drop and full bore flow are essential.

Key Product Categories

-

By Design Configuration:

-

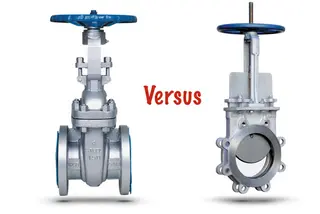

Wedge Gate Valves: Solid, flexible, or split-wedge designs for varying sealing conditions

-

Parallel Slide Gate Valves: Parallel disc design with spring-loaded sealing

-

Knife Gate Valves: Sharp-edged gate for slurry and viscous media applications

-

Through-Conduit Gate Valves: Full-bore design for pipeline pigging operations

-

Expanding Gate Valves: Mechanical expansion for bidirectional sealing (API 6D)

-

-

By Stem Operation:

-

Rising Stem (OS&Y): Stem rises with gate movement for visual position indication

-

Non-Rising Stem (NRS): Compact design where stem rotates but doesn't rise

-

Slab Gate Valves: Through-conduit design with floating gate for pipeline isolation

-

-

By Material Construction:

-

Body Materials: Carbon steel (WCB, LCB), stainless steel (CF8, CF8M), alloy steel (WC6, WC9), bronze, ductile iron

-

Gate Materials: 13% Cr stainless, Stellite-faced, Monel, Inconel, nickel-plated

-

Seat Materials: Metal-to-metal, resilient seated (EPDM, NBR, Viton), PTFE inserts

-

Stem Materials: 316SS, 410SS, Monel, Inconel with hardened surfaces

-

-

By Application Specifications:

-

Oil & Gas: API 6D/6A gate valves for pipelines, wellheads, and refineries

-

Power Generation: High-temperature power plant valves (MSS SP-70/81)

-

Water Distribution: Resilient-seated gate valves (AWWA C500/C509)

-

Marine & Offshore: Bronze and naval brass valves for seawater systems

-

Chemical Processing: Alloy valves for corrosive service

-

Mining & Slurry: Knife gate valves for abrasive media handling

-

Cryogenic Service: Extended bonnet designs for LNG applications (-196°C)

-

Technology & Innovation Trends

-

Advanced Sealing Technology:

-

Double block and bleed (DBB) designs for maintenance safety

-

Fire-safe designs meeting API 607/ISO 10497 standards

-

Cryogenic seat materials for LNG and industrial gases

-

-

Digital Integration:

-

Smart position indicators with wireless HART/Profibus communication

-

IoT-enabled torque monitoring for predictive maintenance

-

Digital twins for wear prediction and remaining life calculation

-

-

Material Science Advancements:

-

Nanostructured coatings for erosion/corrosion resistance

-

Composite materials for weight reduction in large diameter valves

-

Advanced polymer seats for improved cycle life

-

-

Manufacturing Innovation:

-

Automated welding systems for consistent pressure boundary integrity

-

CNC machining with real-time quality monitoring

-

Robotic assembly for high-volume production

-

Global Market Drivers

-

Oil and gas pipeline expansion projects worldwide

-

Power plant construction and refurbishment programs

-

Water infrastructure modernization initiatives

-

Mining and mineral processing industry growth

-

LNG terminal construction and expansion

-

Industrial automation and smart valve adoption

-

Stringent safety and environmental regulations

Major Players & Value Chain

-

Global Leaders: Cameron (Schlumberger), Emerson, Flowserve, Velan, KITZ, IMI

-

Specialty Manufacturers: DeZURIK, Val-Matic, GWC, Weir Group, Cla-Val

-

Regional Manufacturers: China (Zhejiang, Jiangsu clusters), India, Middle East

-

Value Chain: Raw material suppliers → component manufacturing → valve assembly → testing/certification → distributors → EPC contractors → end-users

Challenges & Opportunities

-

Challenges:

-

Extended lead times for large diameter custom valves

-

Seal wear and leakage in high-cycle applications

-

Operational issues with improper installation/maintenance

-

Price competition from alternative valve types

-

Technical skill shortage in specialized valve engineering

-

-

Opportunities:

-

Smart pipeline networks with integrated valve monitoring

-

Hydrogen and CCUS infrastructure development

-

Water conservation and leak reduction programs

-

Aftermarket services and digital upgrades

-

Modular and compact designs for space-constrained applications

-

Emerging market infrastructure development

-

.jpg)