Industry Definition & Scope

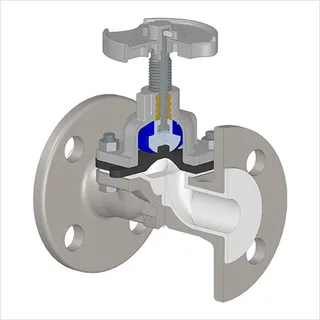

The diaphragm valves industry encompasses the design, manufacturing, and application of valves that utilize a flexible diaphragm as the primary closure element, creating a physical barrier between the process fluid and the valve's internal mechanisms. This specialized sector is particularly valued in industries requiring high purity, sterile conditions, corrosion resistance, and leak-tight operation, serving critical applications in pharmaceutical, biotechnology, food & beverage, water treatment, and chemical processing industries.

Key Product Categories

-

By Design Configuration:

-

Weir-Type Diaphragm Valves: Most common design with a raised weir for enhanced shut-off capability

-

Straight-Through Diaphragm Valves: Full bore design for minimal pressure drop and slurry handling

-

Sanitary Diaphragm Valves: Polished surfaces, crevice-free designs for hygienic applications

-

Lined Diaphragm Valves: PTFE or rubber-lined bodies for aggressive chemical service

-

Multi-Port Diaphragm Valves: 3-way and 4-way configurations for flow diversion and mixing

-

-

By Operation Mechanism:

-

Manual Diaphragm Valves: Handwheel, lever, or pneumatic/hydraulic actuation

-

Pneumatically Actuated: Air-operated for remote or automated control

-

Electrically Actuated: Motor-operated for precise positioning

-

Hydraulically Actuated: For high-force applications

-

Solenoid-Operated: For quick on/off applications

-

-

By Material Construction:

-

Body Materials: Stainless steel (304/316L), cast iron, ductile iron, PVC, CPVC, PP, PVDF

-

Diaphragm Materials:

-

EPDM (ethylene propylene diene monomer): General purpose, water service

-

PTFE (polytetrafluoroethylene): Chemical resistance, high purity

-

FKM (Viton®): High temperature, chemical resistance

-

Butyl: Gas and vacuum service

-

Silicone: High purity, pharmaceutical

-

-

Bonnet & Actuator Materials: Aluminum, stainless steel, engineered plastics

-

-

By Application Specificity:

-

Pharmaceutical/Biotech: Sterile processing, CIP/SIP systems, fermenters, bioreactors

-

Food & Beverage: Product lines, CIP systems, brewing, dairy processing

-

Water & Wastewater: Chemical dosing, sludge handling, potable water

-

Chemical Processing: Corrosive and abrasive fluid handling

-

Semiconductor: Ultra-high purity gas and chemical delivery

-

Mining & Mineral: Slurry and abrasive media handling

-

Technology & Innovation Trends

-

Advanced Diaphragm Technology:

-

Multi-layer composite diaphragms with embedded sensors for wear monitoring

-

Self-diagnostic diaphragms with integrated pressure and temperature sensors

-

Nanocomposite materials enhancing chemical resistance and service life

-

Transparent diaphragm materials for visual flow verification

-

-

Smart Valve Integration:

-

IoT-enabled position and condition monitoring

-

Wireless communication for remote diagnostics and control

-

Predictive maintenance algorithms based on diaphragm cycle counting

-

Integration with process control systems via digital protocols (PROFINET, EtherCAT)

-

-

Hygienic & Clean Design Innovations:

-

Electropolished and mirror-finished surfaces for improved cleanability

-

Zero dead-leg designs eliminating contamination traps

-

Quick-disconnect clamp connections for easy maintenance

-

Sterile barrier integrity monitoring systems

-

-

Sustainability & Efficiency:

-

Reduced-stroke actuators lowering air consumption in pneumatic valves

-

Energy recovery systems in actuation mechanisms

-

Recyclable diaphragm materials and take-back programs

-

Lightweight composite bodies reducing material usage

-

Global Market Drivers

-

Stringent regulatory requirements in pharmaceutical and food industries (FDA, EHEDG, 3-A)

-

Growth in biopharmaceutical manufacturing and single-use technologies

-

Increasing demand for water and wastewater treatment worldwide

-

Expansion of semiconductor manufacturing requiring ultra-clean valve solutions

-

Process automation trends driving demand for actuated diaphragm valves

-

Replacement of traditional valves with diaphragm valves in corrosive applications

-

Focus on reducing cross-contamination in multi-product facilities

-

Growth in microbrewing and craft beverage industries

Major Players & Value Chain

-

Global Specialists:

-

Pharmaceutical/Food Focus: GEMÜ, ITT Engineered Valves, SPX Flow (APV), Alfa Laval

-

Industrial Focus: Saunders (CIRCOR), Georg Fischer, ASAHI/America, Plast-O-Matic

-

High-Purity Focus: Fujikin, Ham-Let, Parker Hannifin (Instrumentation)

-

-

Regional Leaders:

-

Europe: Burkert, Christian Burkert, DK-Lok

-

Asia: Takasago, Nippon Daiya, Chinese manufacturers (Zhejiang, Jiangsu regions)

-

North America: Hayward, Val-Matic, Plast-O-Matic

-

-

Value Chain:

-

Raw material suppliers (elastomers, metals, polymers)

-

Diaphragm manufacturing (molding, vulcanization, coating)

-

Valve body manufacturing (casting, machining, welding)

-

Assembly and testing (pressure, leak, cleanliness)

-

Distribution (specialty distributors, OEM channels)

-

System integration and validation (for regulated industries)

-

Aftermarket services (diaphragm replacement, maintenance)

-

Challenges & Opportunities

-

Challenges:

-

Diaphragm fatigue and limited service life requiring regular replacement

-

High initial cost compared to some alternative valve types

-

Pressure and temperature limitations of diaphragm materials

-

Complex material selection for specific chemical compatibility

-

Counterfeit and substandard diaphragms in price-sensitive markets

-

-

Opportunities:

-

Single-use disposable diaphragm valves for bioprocessing

-

Smart diaphragm technology with predictive maintenance capabilities

-

Expansion in emerging pharmaceutical and biotech markets

-

Customization for specific process requirements

-

Hybrid diaphragm designs combining multiple materials for enhanced performance

-

Digital services including remote monitoring and diaphragm inventory management

-

Sustainable diaphragm materials and recycling programs

-