Industry Definition & Scope

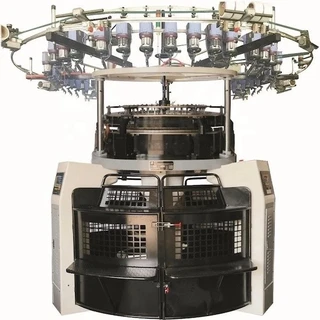

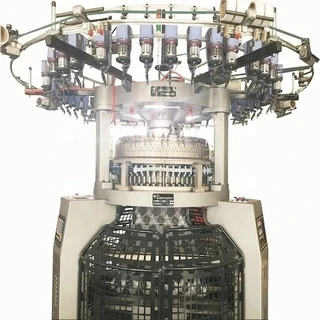

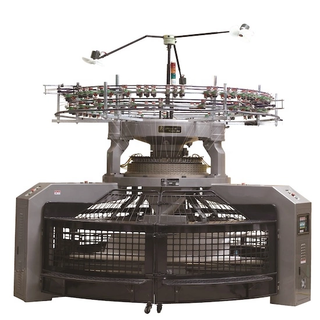

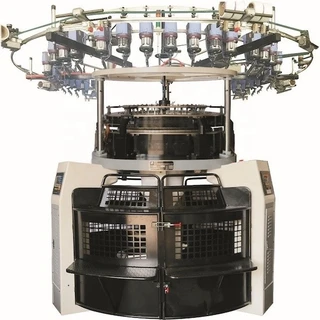

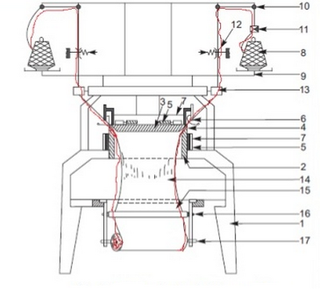

The circular knitting machine industry encompasses the design, manufacturing, and distribution of specialized textile machinery featuring needles arranged in a circular formation to produce seamless tubular fabrics. This advanced sector serves as the technological backbone for producing knitted textiles across apparel, technical, and industrial applications, characterized by high-speed continuous production and versatile fabric creation capabilities.

Key Product Categories

By Machine Construction & Needle Bed Type:

-

Single Jersey Machines: Machines with one set of needles (cylinder needles) producing basic plain knit fabrics with distinct right and wrong sides.

-

Double Jersey/Rib Machines: Machines with two sets of needles (cylinder and dial needles) producing double-faced fabrics with vertical rib structures, offering greater elasticity and thickness.

-

Interlock Machines: Specialized double-knit machines producing smooth, stable fabrics with identical appearance on both sides.

-

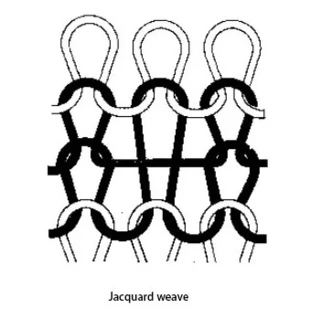

Jacquard Circular Machines: Machines equipped with electronic or mechanical selection devices for creating complex color patterns, textures, and designs.

By Diameter & Application:

-

Small Diameter Machines (1.5" - 4.5"): Primarily for producing seamless hosiery, socks, gloves, and sleeves.

-

Medium Diameter Machines (7" - 22"): For producing body fabrics for T-shirts, underwear, sportswear, and other apparel.

-

Large Diameter Machines (24" - 60"+): For producing wide-width fabrics that are later cut and sewn into various garments.

By Technological Generation:

-

Mechanical Circular Machines: Traditionally controlled by pattern wheels, chain links, or punch cards.

-

Electronic Circular Machines: Computer-controlled with servo motors, digital pattern input, and automated yarn carriers.

-

Computerized Integration Systems: Fully automated systems with CAD/CAM connectivity, real-time monitoring, and production data management.

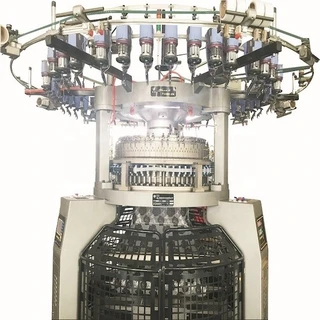

Technology & Innovation Trends

-

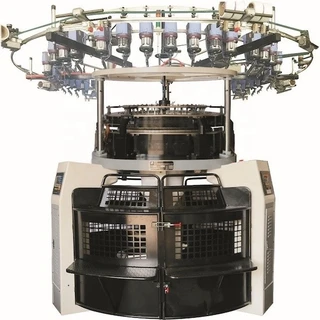

High-Speed Production Capabilities: Modern machines achieving speeds exceeding 50 RPM with multiple feeders for maximum productivity.

-

Multi-Feed & Multi-Cam Systems: Advanced machines featuring 90-144 feeders for complex patterning and reduced production time.

-

Electronic Needle Selection: Individual needle control through piezoelectric or electromagnetic actuators for unlimited patterning possibilities.

-

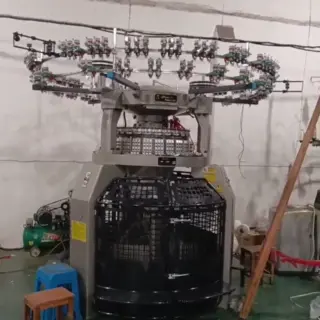

Smart Monitoring & IoT Connectivity: Real-time production monitoring, fault detection, and predictive maintenance through cloud-based systems.

-

Energy-Efficient Drives: Advanced servo motor systems reducing power consumption by 20-40% compared to traditional mechanical drives.

-

Quick-Change Systems: Modular components allowing rapid conversion between different fabric structures and yarn types.

-

Automated Yarn Handling: Integrated systems for automatic creeling, tension control, and defect detection.

Global Market Drivers

-

Fast Fashion & Apparel Industry Demand: Need for rapid, cost-effective production of knitted fabrics for global clothing brands.

-

Athleisure & Sportswear Growth: Increased demand for performance fabrics and seamless construction in activewear.

-

Technical Textile Expansion: Growing applications in medical textiles, automotive interiors, and industrial fabrics.

-

Labor Cost Optimization: Automation reducing dependency on skilled labor in textile manufacturing.

-

Sustainability Requirements: Machines enabling production with recycled fibers and minimizing waste through efficient knitting.

-

Supply Chain Regionalization: Re-establishment of textile manufacturing capacities in various regions driving machinery investment.

Industry Value Chain

-

Raw Material & Component Suppliers: Specialized steel manufacturers, precision gear producers, electronic component suppliers, and control system developers.

-

Machine Manufacturers: Global and regional companies producing complete circular knitting systems.

-

Software & Control System Developers: Companies providing pattern design, machine control, and production management software.

-

Distributors & Service Networks: Regional representatives providing sales, installation, and technical support.

-

Spare Parts & Accessories Suppliers: Manufacturers of needles, sinkers, cams, and other consumable components.

-

End Users: Textile mills, apparel manufacturers, technical textile producers, and fabric converters.

Key Industry Challenges

-

High Capital Investment: Significant upfront costs limiting accessibility for small and medium enterprises.

-

Technical Complexity: Requirement for highly trained technicians for operation, maintenance, and programming.

-

Competition from Alternative Technologies: Competition from warp knitting and woven fabric technologies in certain applications.

-

Rapid Technological Obsolescence: Fast pace of innovation requiring frequent machine upgrades.

-

Global Economic Sensitivity: Cyclical demand tied to apparel consumption and textile industry health.

-

Supply Chain Disruptions: Dependence on specialized components from limited global suppliers.

-

Environmental Regulations: Compliance with energy consumption and noise emission standards.

Future Outlook

The circular knitting machine industry is advancing toward smarter, more sustainable, and highly integrated production systems.

-

Digital Twin Technology: Virtual replicas of machines for simulation, optimization, and remote troubleshooting.

-

Artificial Intelligence Integration: Machine learning algorithms for automatic defect detection, pattern optimization, and production planning.

-

Sustainable Production Systems: Machines specifically designed for recycled fibers, biodegradable yarns, and minimal resource consumption.

-

Customization & Small-Batch Capabilities: Flexible systems enabling economical production of customized and small-lot fabrics.

-

Complete Smart Factory Integration: Seamless connectivity with upstream and downstream processes in fully automated textile plants.

-

Advanced Seamless Technologies: Development of complete garment knitting on circular machines with integrated shaping capabilities.

-

Global Service Networks: Enhanced remote diagnostic and maintenance capabilities through augmented reality and IoT platforms.