Industry Definition & Scope

The ceramic valves industry encompasses the design, manufacturing, and application of industrial valves utilizing advanced ceramic materials (primarily alumina, zirconia, silicon carbide, and silicon nitride) for critical components. This specialized sector addresses extreme operating conditions where conventional metallic valves fail, offering exceptional wear resistance, corrosion immunity, high-temperature stability, and chemical inertness for abrasive, corrosive, and high-purity applications across mining, chemical processing, power generation, and semiconductor industries.

Key Product Categories

-

By Ceramic Material Type:

-

Alumina (Al₂O₃) Valves: 92-99.9% purity grades for general abrasion and corrosion resistance

-

Zirconia (ZrO₂) Valves: Partially stabilized (PSZ) and fully stabilized for high toughness and thermal shock resistance

-

Silicon Carbide (SiC) Valves: Reaction-bonded and sintered types for extreme abrasion and chemical environments

-

Silicon Nitride (Si₃N₄) Valves: High-strength, thermal shock resistant for high-temperature applications

-

Composite Ceramics: Ceramic-metal composites (cermets) and ceramic-polymer hybrids

-

-

By Valve Type & Design:

-

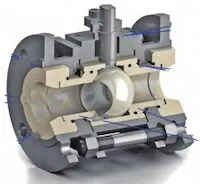

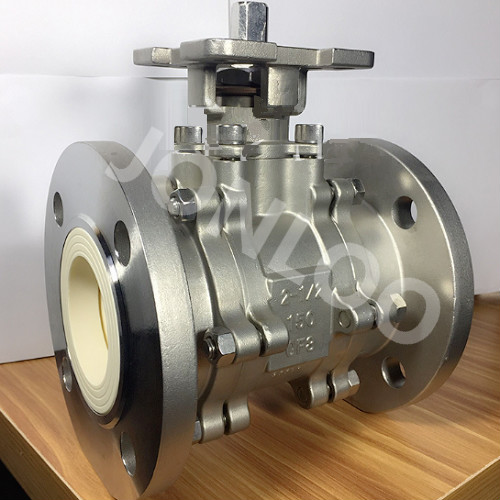

Ceramic Ball Valves: Quarter-turn valves with ceramic balls and seats for slurry services

-

Ceramic Gate Valves: Knife-gate and wedge-gate designs for abrasive media isolation

-

Ceramic Check Valves: Spring-assisted and swing types for corrosive fluid backflow prevention

-

Ceramic Control Valves: Trim parts (plugs, seats) for throttling abrasive/corrosive flows

-

Ceramic Diaphragm Valves: For ultra-pure and sterile processing in pharmaceutical/food industries

-

Specialized Designs: Ceramic-lined valves, double-block-and-bleed ceramic valves

-

-

By Application Industry:

-

Mining & Mineral Processing: Tailings, ore slurries, concentrate pipelines

-

Chemical & Petrochemical: Acid, alkali, solvent, and catalyst handling

-

Power Generation: Fly ash, bottom ash, flue gas desulfurization (FGD) systems

-

Semiconductor & Electronics: Ultra-high purity gas and chemical delivery systems

-

Pharmaceutical & Biotechnology: Sterile processing, CIP/SIP systems

-

Water & Wastewater: Desalination, abrasive water, chemical dosing

-

Pulp & Paper: Stock preparation, chemical recovery, bleaching systems

-

-

By Performance Characteristics:

-

Abrasion Resistance: For services with solid particle content exceeding 5-10%

-

Corrosion Resistance: Handling acids (HF, HCl, H₂SO₄), alkalis, and organic solvents

-

High-Temperature Capability: Continuous operation up to 1600°C in specific ceramics

-

High-Purity Applications: Ceramic-to-ceramic sealing preventing contamination

-

Technology & Innovation Trends

-

Advanced Ceramic Manufacturing:

-

Net-shape and near-net-shape forming reducing machining costs

-

Hot isostatic pressing (HIP) for defect-free, high-density components

-

Additive manufacturing (3D printing) of complex ceramic valve parts

-

Laser processing for precision surface finishing and sealing surfaces

-

-

Material Science Innovations:

-

Nanostructured ceramics for enhanced mechanical properties

-

Gradient and composite materials optimizing wear and impact resistance

-

Self-lubricating ceramic composites reducing friction

-

Transparent ceramics for visual flow monitoring in critical applications

-

-

Design & Engineering Advances:

-

Finite element analysis (FEA) for stress optimization in ceramic components

-

Modular designs allowing ceramic trim replacement in metallic bodies

-

Cryogenic and high-temperature sealing technologies

-

Integrated sensors for wear monitoring and predictive maintenance

-

-

Testing & Quality Assurance:

-

Non-destructive testing (ultrasonic, X-ray) for internal defect detection

-

Wear testing under simulated service conditions

-

Corrosion testing per ASTM and ISO standards

-

Cyclic fatigue testing for high-cycle applications

-

Global Market Drivers

-

Increasing severity of industrial processes requiring extreme material performance

-

Growth in mining activities and mineral processing worldwide

-

Stringent environmental regulations driving zero-leakage valve requirements

-

Expansion of semiconductor and electronics manufacturing

-

Water scarcity driving desalination and aggressive water treatment

-

Chemical industry capacity expansion in Asia and Middle East

-

Replacement demand for failed metallic valves in abrasive/corrosive services

-

Advancements in ceramic manufacturing reducing costs and expanding applications

Major Players & Value Chain

-

Global Ceramic Valve Specialists:

-

Mining & Heavy Industry: Weir Minerals, Metso, GIW Industries, Schaffner

-

Industrial Process: Flowserve, KSB, Xylem, Neles

-

High-Purity Applications: Fujikin, CKD, Parker Hannifin (specified lines)

-

-

Ceramic Material Suppliers:

-

CoorsTek, Kyocera, Morgan Advanced Materials, CeramTec

-

-

Regional Manufacturers:

-

China: Jiangsu Lianggong, Shanghai Karon, Ningbo Better

-

Japan: TOTO, NGK Insulators

-

Europe: Saint-Gobain Ceramics, Ceramaret

-

-

Value Chain:

-

Raw material processing (alumina/zirconia/silicon powders)

-

Ceramic component forming and sintering

-

Precision machining and finishing

-

Valve assembly with metallic/other components

-

Testing and certification

-

Distribution to OEMs and end-users

-

Field service and technical support

-

Challenges & Opportunities

-

Challenges:

-

Brittle nature requiring careful handling and installation

-

Higher initial cost compared to metallic alternatives

-

Limited size range for monolithic ceramic components

-

Specialized machining and joining techniques

-

Thermal expansion mismatch with metallic components

-

-

Opportunities:

-

Additive manufacturing enabling complex ceramic geometries

-

Expansion in hydrogen economy applications (corrosive hydrogen services)

-

Digitalization with embedded sensors in ceramic components

-

Growth in lithium mining and battery chemical processing

-

Nuclear industry applications for next-generation reactors

-

Water treatment in developing regions with aggressive water chemistry

-

Lightweight ceramic valves for aerospace and defense applications

-

.jpg)

.jpg)

.jpg)