Industry Definition & Scope

The blind flanges industry encompasses the design, manufacturing, and application of solid, disc-shaped piping components without a central bore, used to terminate, seal, or isolate piping systems, vessels, and equipment. As critical safety and maintenance components, blind flanges provide positive isolation for pressure testing, system segregation, and future expansion points across industrial, energy, and infrastructure sectors.

Key Product Categories

-

By Design Configuration:

-

Standard Blind Flanges: Solid disc with bolt holes matching standard flange dimensions

-

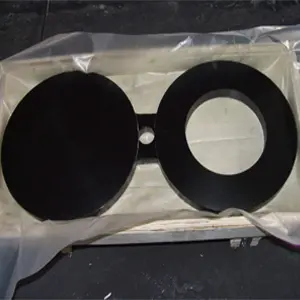

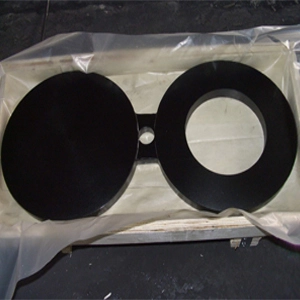

Spectacle Blinds (Spade & Spacers): Combined blind and spacer for permanent isolation points

-

Paddle Blinds (Skillet/Line Blinds): Single-piece removable blinds for frequent isolation

-

Orifice Flanges: With integral pressure tapping for flow measurement

-

Raised Face Blinds: Standard facing for gasket sealing

-

Ring-Type Joint (RTJ) Blinds: Metal-to-metal sealing for high-pressure applications

-

-

By Pressure Rating:

-

ANSI/ASME Classes: 150, 300, 600, 900, 1500, 2500

-

PN Ratings: PN6, PN10, PN16, PN25, PN40, PN64, PN100, PN150, PN250

-

API Specifications: API 6A for wellhead equipment, API 17D for subsea

-

-

By Material Composition:

-

Carbon Steel: ASTM A105, A350 LF2 for general service

-

Stainless Steel: ASTM A182 F304/F316/L for corrosive environments

-

Alloy Steel: ASTM A182 F11/F22/F91 for high-temperature service

-

Duplex/Super Duplex: For offshore and chemical applications

-

Special Alloys: Inconel, Monel, Hastelloy, Titanium

-

Non-Metallic: FRP, PVC with metallic reinforcement for specific applications

-

-

By Application Specifications:

-

Process Industry: Pressure vessel manways, reactor closures

-

Pipeline Systems: Line isolation, pigging launch/receive traps

-

Power Generation: Steam line isolation, turbine bypass systems

-

Oil & Gas: Wellhead isolation, Christmas tree components

-

Marine & Offshore: Sea chest closures, tank bulkhead isolation

-

Water Treatment: Tank and basin isolation points

-

Technology & Innovation Trends

-

Advanced Manufacturing Techniques:

-

CNC precision machining for perfect flatness and surface finish

-

Robotic welding for clad and overlay blind flanges

-

3D laser scanning for dimensional verification

-

Automated ultrasonic testing for material integrity

-

-

Material Innovations:

-

Nanostructured coatings for corrosion/erosion resistance

-

Bimetallic construction for cost-performance optimization

-

Composite materials for weight reduction in offshore applications

-

Cryogenic materials for LNG and industrial gas services

-

-

Smart Integration:

-

RFID tagging for asset tracking and maintenance history

-

Smart blinds with integrated pressure/temperature sensors

-

Quick-release designs for rapid isolation in emergency situations

-

Digital twin integration for flange management systems

-

-

Safety & Sustainability:

-

Fugitive emission control designs with advanced gasket systems

-

Lightweight designs for easier handling and installation

-

Recyclable material selection and manufacturing processes

-

Energy-efficient heat treatment and coating processes

-

Global Market Drivers

-

Increasing safety regulations requiring positive isolation in process industries

-

Oil & gas pipeline expansion and integrity management programs

-

Power plant maintenance, modification, and upgrade activities

-

Chemical plant turnarounds and safety system enhancements

-

Water and wastewater infrastructure development

-

LNG terminal construction and expansion projects

-

Offshore wind farm installation and maintenance requirements

-

Industrial automation driving systematic isolation practices

Major Players & Value Chain

-

Global Leaders: Texas Flange, Pro-Flange, Metal Udyog, Flange Guard, RMP Products

-

Integrated Manufacturers: Flowserve, Velan, Emerson, KITZ, IMI

-

Regional Specialists: China (Jiangsu Sheye, Cangzhou Longtain), India, Southeast Asia

-

Value Chain: Steel mills/forging shops → machining → coating/heat treatment → testing/certification → distributors → EPC contractors → end-users

Challenges & Opportunities

-

Challenges:

-

Weight and handling difficulties for large diameter blinds

-

Corrosion and sealing issues in harsh environments

-

Lead time pressures for custom and specialized materials

-

Safety risks during installation/removal in live systems

-

Price competition from non-standard manufacturers

-

-

Opportunities:

-

Smart pipeline management systems integration

-

Hydrogen and CCUS infrastructure development

-

Modular plant construction driving standardized components

-

Digital inventory and on-demand manufacturing

-

Aftermarket services: refurbishment, coating renewal, certification

-

Emerging market infrastructure growth

-