Industry Definition & Scope

The ball valves industry encompasses the design, manufacturing, and distribution of quarter-turn valves that use a perforated, pivoting ball to control fluid flow. Known for their reliability, tight sealing, and quick operation, ball valves are essential components in industrial fluid systems across energy, chemical, water management, and general manufacturing sectors.

Key Product Categories

-

By Design Configuration:

-

Floating Ball Valves: Ball floats between seats, suitable for low-medium pressure

-

Trunnion-Mounted Ball Valves: Ball fixed on trunnions, for high-pressure/large diameter

-

Top-Entry Valves: Maintenance-friendly design with removable bonnet

-

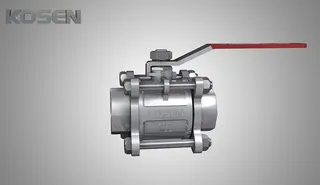

Side-Entry/Split-Body Valves: Three-piece construction for easy servicing

-

Fully Welded Valves: Permanent pipeline installation with maximum integrity

-

-

By Material Construction:

-

Body Materials: Carbon steel, stainless steel (CF8/CF8M), alloy steel, bronze, brass, PVC, CPVC

-

Ball Materials: Chrome-plated steel, 316SS, Monel, ceramic-coated, PFA-lined

-

Seat Materials: PTFE (Teflon), reinforced PTFE, Nylon, Delrin, metal-seated (Stellite)

-

Seal Materials: Viton, EPDM, Buna-N, Kalrez for chemical compatibility

-

-

By Application Specifications:

-

Standard Pressure: ANSI Class 150-600, PN10-PN100

-

High-Pressure: ANSI Class 900-2500, nuclear applications

-

Cryogenic Service: Extended stems for LNG applications (-196°C)

-

High-Temperature: Metal-seated valves for >400°C service

-

Sanitary/Hygienic: Tri-clamp, polished finishes for food/pharma

-

Fire-Safe: API 607/ISO 10497 certified with secondary metal seals

-

-

By Actuation & Control:

-

Manual: Lever, gear-operated, pneumatic/hydraulic actuators

-

Automated: Electric, pneumatic, hydraulic actuation

-

Smart Valves: IoT-enabled with sensors for position, torque, temperature monitoring

-

Control Valves: V-port or characterized ball for precise flow regulation

-

Technology & Innovation Trends

-

Digital Integration:

-

WirelessHART/ISA100 compatible smart valve positioners

-

Predictive maintenance through vibration and torque analytics

-

Digital twins for valve performance simulation

-

-

Advanced Materials:

-

Nanocomposite seats for extended cycle life

-

Cryogenic coatings for LNG and hydrogen applications

-

Corrosion-resistant alloys for offshore and chemical service

-

-

Manufacturing Excellence:

-

Robotic welding for consistent weld quality

-

CNC machining with AI-powered quality inspection

-

Additive manufacturing for complex prototypes and spare parts

-

-

Sustainability Focus:

-

Low-emission designs meeting ISO 15848-1 fugitive emission standards

-

Energy-efficient actuation systems

-

Recyclable material selection and packaging

-

Global Market Drivers

-

Energy infrastructure expansion (oil & gas pipelines, LNG terminals, hydrogen systems)

-

Water and wastewater treatment plant construction worldwide

-

Industrial automation and IIoT adoption in process industries

-

Replacement demand in aging petrochemical and power facilities

-

Stringent environmental regulations on emissions and leak prevention

-

Growth in pharmaceutical, food & beverage processing industries

Major Players & Value Chain

-

Global Leaders: Emerson (Fisher), Flowserve, Cameron (Schlumberger), KITZ, IMI PLC, Velan

-

Specialty Manufacturers: Apollo Valves, Swagelok, Parker Hannifin, Bray International

-

Regional Champions: Dazhong Valve (China), L&T Valves (India), Valvitalia (Italy)

-

Value Chain: Raw material suppliers → component manufacturers → valve assembly → testing/certification → distribution network → system integrators → end users

Challenges & Opportunities

-

Challenges:

-

Intense price competition from commoditized products

-

Raw material cost volatility (special alloys, polymers)

-

Technical skill shortage in valve engineering and maintenance

-

Counterfeit products in emerging markets

-

-

Opportunities:

-

Digital valve services and performance contracts

-

Hydrogen economy valve development and certification

-

Water conservation and smart water network solutions

-

Aftermarket services (repair, refurbishment, retrofitting)

-

Growth in Asia-Pacific infrastructure projects

-

Videos

More About Ball Valves

What are the key standards and certifications for industrial ball valves?

Adherence to standards ensures performance, safety, and interchangeability.

-

Design & Pressure Ratings: ASME B16.34 (fundamental design), API 6D (specifically for pipeline and industrial ball valves), ISO 17292 (international metal ball valve standard).

-

Fire Safety: API 607 / ISO 10497 (Fire Test for Soft-Seated Quarter-Turn Valves). Certifies that the valve will not externally leak for a specified time during a fire after the soft seats have burned away.

-

End Connections: ASME B16.5 (Flanged), ASME B16.11 (Threaded/Socket Weld).

-

Face-to-Face Dimensions: ASME B16.10 / ISO 5752 (ensures valves from different manufacturers are dimensionally interchangeable in a pipeline).

-

Industry-Specific: 3-A Sanitary Standard (for food, beverage, pharmaceuticals), ATEX / IECEx (for valves used in explosive atmospheres).

What does "blow-out proof stem" mean, and why is it important?

Importance: It prevents catastrophic failure and ensures operator safety. If high internal pressure could force the stem out, it would create a dangerous, uncontrolled release of process fluid. Most modern industrial ball valve standards (like API 6D) require this feature.

What are the main types of ball valve seat materials, and how do I choose?

The seat material is critical for sealing, temperature resistance, and chemical compatibility.

-

PTFE (Teflon): Most common. Offers excellent chemical resistance and low friction but is limited by temperature (typically -50°C to 200°C / -58°F to 392°F) and can be prone to cold flow (deformation under load).

-

Reinforced PTFE (e.g., Glass-filled, Carbon-filled): Improves mechanical strength, reduces cold flow, and slightly increases temperature limits.

-

PEEK (Polyether Ether Ketone): A high-performance thermoplastic with excellent chemical and thermal resistance (up to 260°C / 500°F), superior to PTFE in harsh conditions.

-

Metal Seats (e.g., Stainless Steel, Inconel): Used for extreme temperatures (cryogenic or high-heat), abrasive slurries, or where fire-safe certification is required (after a soft seat burns away, metal seats provide a secondary seal).

Selection Guide: Match seat material to the fluid's chemical compatibility, continuous operating temperature, pressure, and any required certifications (FDA, USP Class VI for sanitary applications).