Difference Between Double and Single Jersey Circular Knitting Machines

Introduction

Knitting is one of the most essential and versatile methods of textile manufacturing. It involves the interlooping of yarns to form fabric, a technique that has evolved dramatically over centuries. While hand knitting dates back to ancient times, modern industrial knitting owes much of its efficiency to circular knitting machines. These machines are designed to produce large volumes of knitted fabric quickly, meeting the high demands of the fashion, sportswear, and home textile industries.

Among the wide array of knitting technologies available today, single jersey and double jersey circular knitting machines are two of the most prominent. Each has distinct construction, capabilities, and applications. Understanding the differences between them is essential for manufacturers, designers, and textile engineers aiming to produce specific fabric qualities.

In this article, we delve into the core differences between single and double jersey circular knitting machines—highlighting their working principles, structural outputs, key advantages and disadvantages, and ideal applications.

What is a Single Jersey Circular Knitting Machine?

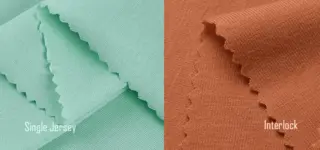

A single jersey circular knitting machine is a weft knitting machine equipped with only one set of needles mounted on a single cylinder. As the name implies, it produces single-faced fabrics, meaning the structure appears different on the front and back sides. The front typically features vertical columns of knit stitches, while the reverse displays horizontal loops.

These machines operate with latch needles and are generally simpler in design and operation than double jersey machines. The fabrics produced are lightweight, stretchy, and widely used in T-shirts, undergarments, casual wear, and sportswear.

Key Characteristics of Single Jersey Circular Knitting Machine

Needle Configuration: Single set of needles on a cylinder

Fabric Type: One-sided (face and back look different)

Gauge: Available in fine to coarse gauges

Stitch Type: Primarily plain knit, but variations like pique and mesh are possible

Advantages of Single Jersey Machines

High Production Speed

Due to their simpler configuration, single jersey machines operate at higher speeds, allowing mass production in minimal time.

Lower Yarn Consumption and Wastage

These machines use less yarn per square meter of fabric, resulting in cost savings and reduced waste.

Ease of Operation

The machinery is less complex, making it easier to set up, maintain, and operate—especially suitable for less experienced operators.

Versatility in Lightweight Fabrics

Ideal for producing breathable, stretchable, and soft fabric structures used in everyday garments.

Cost-Effective Investment

Single jersey machines are generally more affordable, both in terms of initial investment and operational expenses.

Limitations of Single Jersey Circular Knitting Machine

Fabric Curling: Edges of single jersey fabric tend to curl, requiring additional processing for stability.

Limited Thickness: Cannot produce thicker or double-layered fabrics.

Less Dimensional Stability: These fabrics are prone to distortion after washing if not treated correctly.

What is a Double Jersey Circular Knitting Machine?

A double jersey circular knitting machine—sometimes referred to as an interlock or rib machine—features two sets of needles mounted on both a cylinder and a dial. This configuration allows the machine to produce double-faced fabrics where both sides are structurally identical or symmetrically constructed.

Double jersey machines create thicker, more stable, and more durable fabrics. These fabrics are commonly used in garments where structure, warmth, and opacity are required—such as leggings, jackets, sweaters, and upholstery.

Key Characteristics of Double Jersey Circular Knitting Machine

Needle Configuration: Two needle beds (cylinder and dial) operating together

Fabric Type: Double-sided (front and back have similar or identical appearance)

Stitch Variations: Rib, interlock, and purl structures

Cam Systems: Complex cam arrangements allow advanced patterning

Advantages of Double Jersey Machines

Thicker and Warmer Fabric Output

Double-layered fabrics provide insulation and are ideal for colder climates and durable applications.

Excellent Dimensional Stability

Due to the intermeshed structure, fabrics resist curling and deformation during washing and wear.

Capability for Complex Patterns

Advanced double jersey machines can knit intricate rib or jacquard patterns for high-end fashion and technical applications.

Wide Application Range

Suitable for both fashion and industrial textiles—ranging from sweaters to seat covers.

Enhanced Comfort and Fit

Rib knits offer superior elasticity and body-conforming fit, commonly used in cuffs, waistbands, and sportswear.

Limitations of Double Jersey Circular Knitting Machine

Slower Production Speed

The mechanical complexity and dual knitting action often reduce production speed compared to single jersey machines.

Higher Investment and Maintenance Costs

More sophisticated components result in a higher cost of purchase, training, and upkeep.

Increased Yarn Usage

Producing thicker fabrics requires more yarn, contributing to higher material costs.

Comparison Table: Single Jersey vs Double Jersey Circular Knitting Machine

|

Feature |

Single Jersey Machine |

Double Jersey Machine |

|

Needle Arrangement |

Single set (cylinder) |

Two sets (cylinder and dial) |

|

Fabric Structure |

One-sided |

Double-sided |

|

Thickness of Fabric |

Thin, lightweight |

Thick, durable |

|

Elasticity |

Good in one direction |

Excellent in both directions |

|

Speed |

High |

Moderate to low |

|

Cost |

Lower machine and yarn cost |

Higher investment and yarn consumption |

|

Applications |

T-shirts, underwear, activewear |

Jackets, sweaters, upholstery |

|

Fabric Curling |

Yes |

Minimal to none |

|

Pattern Complexity |

Basic patterns |

Advanced rib and interlock designs |

|

Dimensional Stability |

Lower, prone to deformation |

Higher, maintains shape |

Applications in the Textile Industry

Single Jersey Machine Applications

T-Shirts & Tops: Lightweight, breathable, and cost-effective

Sportswear: Allows for excellent moisture management and flexibility

Casual Wear: Everyday garments that require softness and comfort

Innerwear: Due to its softness and stretch, single jersey is ideal for undergarments

Double Jersey Machine Applications

Sweaters and Outerwear: Thicker fabric ensures warmth and durability

Sports Uniforms: Offers stretch and strength needed for active movement

Home Textiles: Fabrics for blankets, cushion covers, and upholstery

Industrial Knits: Seat covers, technical fabrics for filtration or medical use

Innovation and Automation Trends

With advancements in digital control systems and smart manufacturing, modern single and double jersey machines are increasingly automated. Some machines now integrate:

Computerized Jacquard systems for advanced pattern control

Servo motors for precise needle movement

Touchscreen interfaces for ease of operation

Real-time yarn tension control

Automatic doffing and batching systems

These upgrades significantly reduce labor dependency, improve fabric consistency, and enhance production flexibility. Manufacturers are also adopting IoT-based monitoring for predictive maintenance and productivity tracking.

Choosing Between Single and Double Jersey Machines

When selecting a circular knitting machine, consider the following factors:

End Use of the Fabric: Determine whether the fabric needs to be soft and breathable (single jersey) or structured and warm (double jersey).

Fabric Weight and Thickness: If bulk or insulation is needed, double jersey is more suitable.

Budget: For startups or cost-sensitive projects, single jersey machines offer a more affordable entry point.

Pattern Complexity: If your fabric requires ribs, cables, or jacquard designs, a double jersey machine is essential.

Production Volume: Single jersey machines offer higher throughput for mass production of basic knits.

Conclusion

Single jersey and double jersey circular knitting machines both serve critical roles in the textile industry, but they differ significantly in structure, function, and application. While single jersey machines are ideal for lightweight, cost-effective fabrics, double jersey machines excel in producing high-quality, durable, and warm fabrics for a wider range of end uses.

Understanding these differences empowers textile manufacturers and designers to make informed decisions, optimize production processes, and deliver products that align with market demands. As knitting technology continues to evolve, integrating digital controls, automation, and eco-friendly innovations, both machine types are set to remain indispensable tools in the future of textile manufacturing.

Send your message to this supplier

Related Articles from the Supplier

Related Articles from China Manufacturers

Related Products Mentioned in the Article

Supplier Website

Source: https://www.xmnyuanda.com/news/difference-between-double-and-single-jersey-circular-knitting-machines.html